Processing method of complete stool corn green fodder

A whole-plant corn and silage technology, which is applied in the field of whole-plant corn silage processing, can solve the problems of nutrient loss and impact on the quality of silage land, and achieve faster acidification speed, high plant utilization rate, and good anaerobic growth and reproduction conditional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

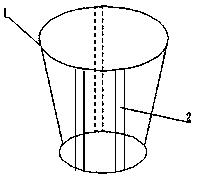

[0021] see figure 1 Shown, a kind of processing method of whole-plant corn silage comprises the following steps: (1) selection of corn harvesting period, harvesting the whole-plant corn which is in the wax ripening period 5 days ahead of schedule;

[0022] (2) preparing silage raw materials, cutting the whole corn plant short within 1-2 days after harvesting, to obtain silage raw materials with a length of 1-1.5 cm and a moisture content of 65%-75%;

[0023] (3) Add silage additives to the prepared silage raw materials; the additives include 3 parts by weight of Pediococcus lactis, 10 parts of Pediococcus pentosaceae, 6 parts of Lactobacillus plantarum, 1 part of Lactobacillus rhamnosus, and 15 parts of glycanase;

[0024] (4) Clean up the silage pit 1: clean and disinfect the silage pit 1, excavate drainage ditches around the silage pit 1, the distance between the drainage ditch and the bottom edge of the cellar wall is 0.8-1.5m, The bottom of the cellar is laid with choppe...

Embodiment 2

[0034] A method for processing whole-plant corn silage, comprising the following steps: (1) selecting the corn harvesting period, harvesting the whole-plant corn that is in the wax ripening period 7 days earlier;

[0035] (2) preparing silage raw materials, cutting the whole corn plant short within 1-2 days after harvesting, to obtain silage raw materials with a length of 1-1.5 cm and a moisture content of 65%-75%;

[0036] (3) Add silage additives to the prepared silage raw materials; the additives include 5 parts by weight of Pediococcus lactis, 15 parts of Pediococcus pentosaceae, 3 parts of Lactobacillus plantarum, 3 parts of Lactobacillus rhamnosus, and 20 parts of glycanase;

[0037] (4) Clean up the silage pit 1: clean and disinfect the silage pit 1, excavate drainage ditches around the silage pit 1, the distance between the drainage ditch and the bottom edge of the cellar wall is 0.8-1.5m, The bottom of the cellar is laid with chopped straw or soft grass with a thickn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com