Cooker, cooking utensil assembly and manufacture method of cooker

A technology for cooking utensils and substrates, which is applied in the field of kitchen utensils, can solve the problems that the heating plate is difficult to achieve three-dimensional heating, affects the environment, iron is easy to rust, etc., and achieves the effects of compact structure, avoiding pollution, and enhancing bonding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

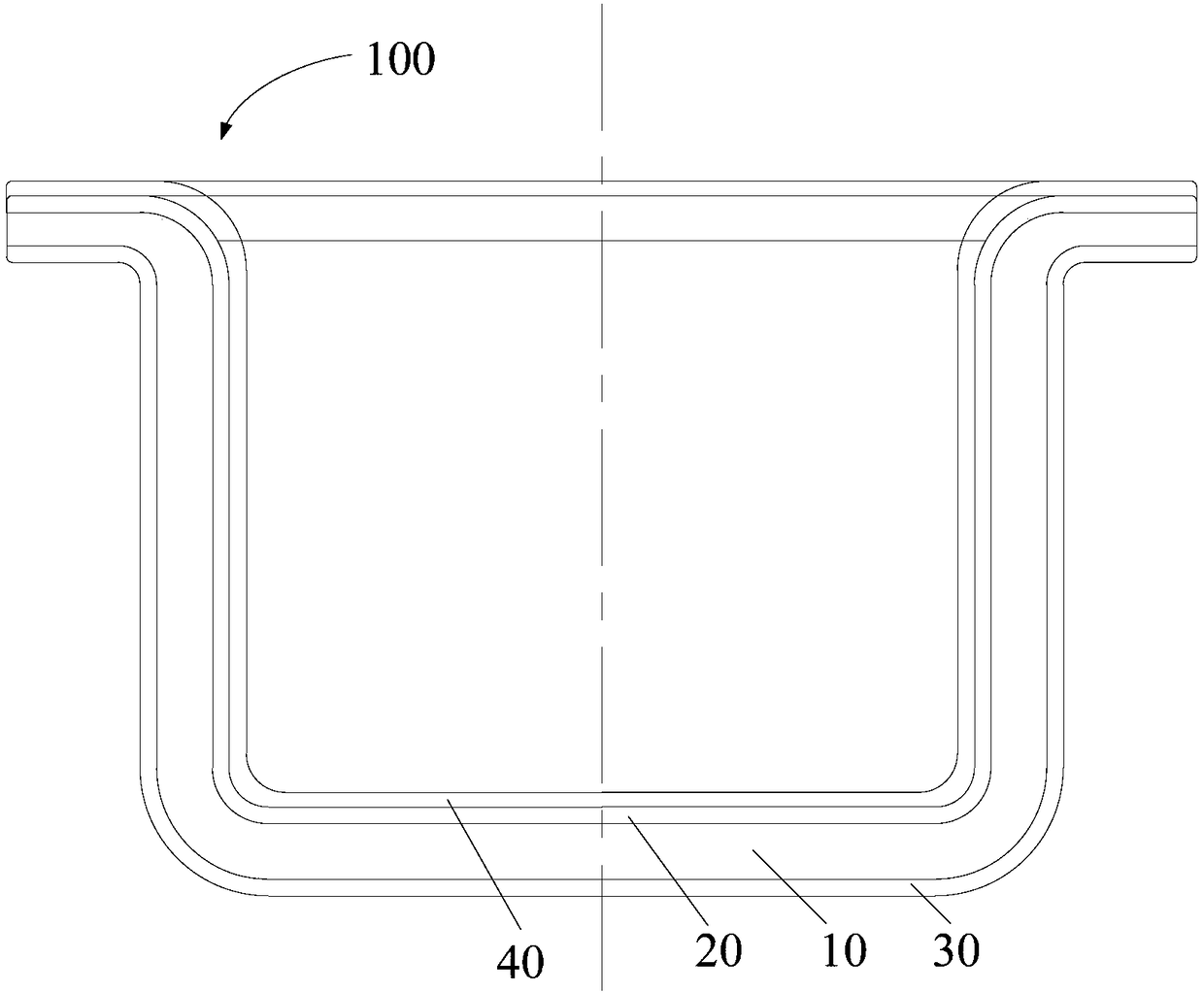

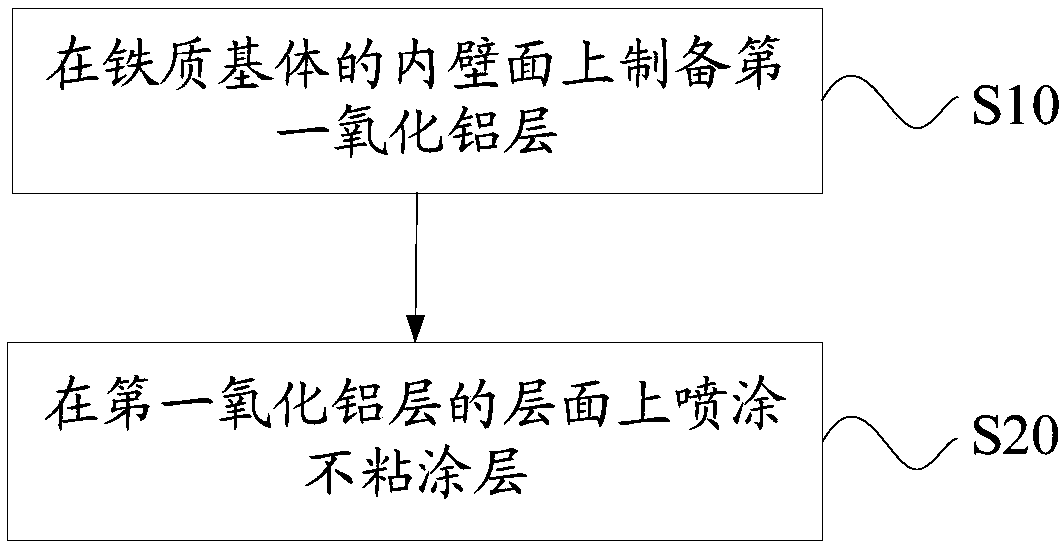

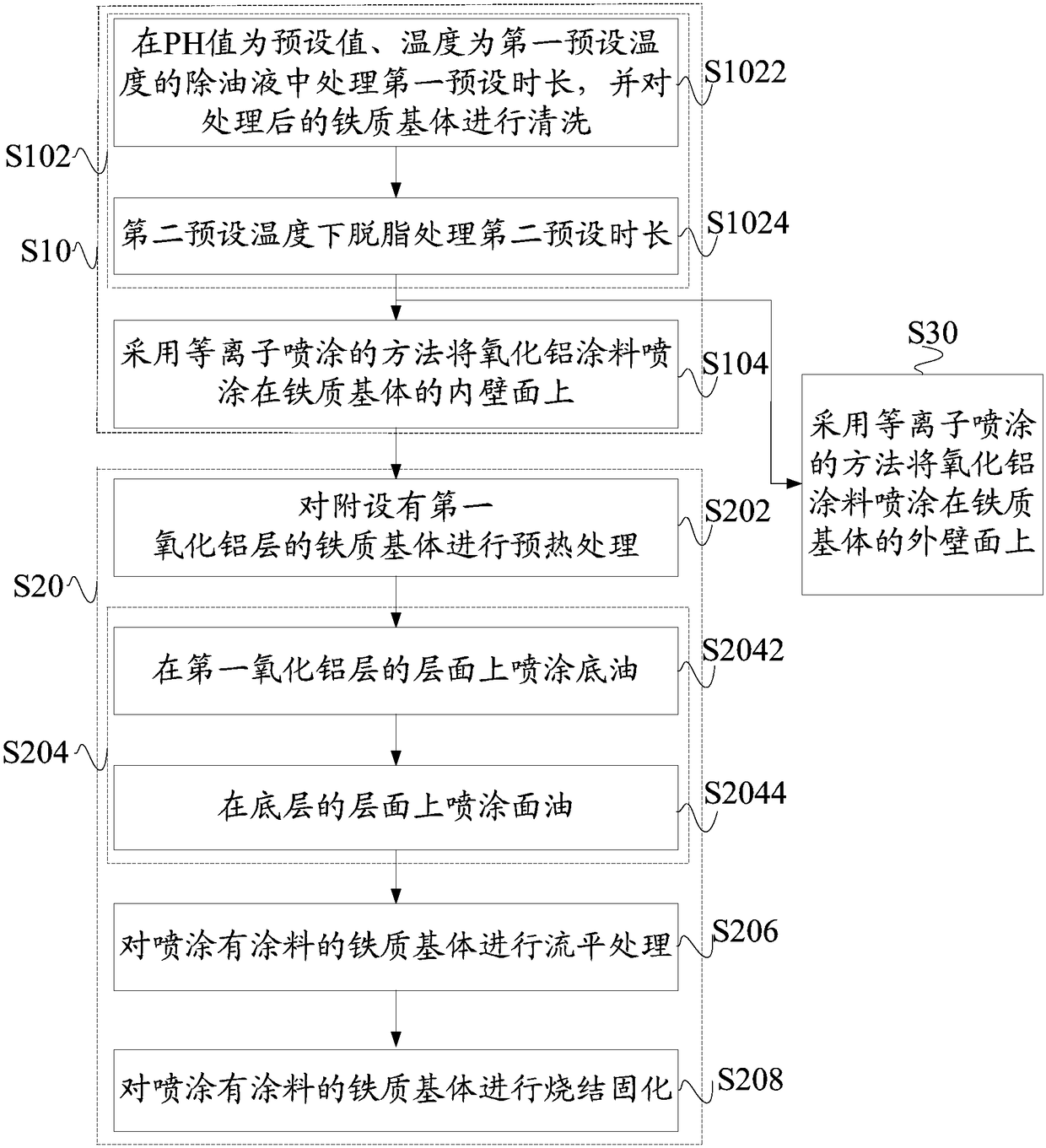

[0093] The embodiment of the third aspect of the present invention provides a preparation method of the cooker 100, which is used to prepare the cooker 100 of any of the above embodiments, such as figure 2 As shown, the preparation method includes: step S10, preparing the first alumina layer 20 on the inner wall surface of the iron substrate 10; step S20, spraying the non-stick coating 40 on the layer of the first alumina layer 20.

[0094] The preparation method of the cooker 100 provided by the embodiment of the third aspect of the present invention includes preparing an alumina layer on the inner wall surface of the ferrous base 10, so as to form a first alumina layer 20 on the inner wall surface of the ferrous base 10, A non-stick coating 40 is sprayed on the level of the first aluminum oxide layer 20 . The first aluminum oxide layer 20 is used as an intermediate layer between the non-stick coating 40 and the inner wall surface of the iron substrate 10, and fully utilizes...

Embodiment 1

[0126] Treat at 50°C for 5 minutes in a degreasing solution with a pH value of 8;

[0127] Use deionized water to spray the iron substrate, the spray pressure is 0.2MPa, and the temperature of deionized water is 50°C;

[0128] After the spray treatment, the iron substrate is cleaned with deionized water, and the temperature of the deionized water is 50°C;

[0129] Carry out high-temperature degreasing treatment on the iron substrate, the treatment temperature is 320°C, and the treatment time is 10 minutes;

[0130] The aluminum oxide paint is sprayed on the inner and outer walls of the iron substrate by plasma spraying, where the spraying distance is 90mm, the spraying power is 60W, the spraying current is 480A, the powder feeding rate is 15g / min, and the flow rate of the working gas Ar 30L / min, auxiliary gas H 2 The flow rate is 1L / min, and the film thickness of the first aluminum oxide layer and the second aluminum oxide layer is 50 μm;

[0131] Preheating the ferrous sub...

Embodiment 2

[0138] Treat in a degreasing solution with a pH value of 8.5 at 55°C for 8 minutes;

[0139] Use deionized water to spray the iron substrate, the spray pressure is 0.3MPa, and the temperature of deionized water is 55°C;

[0140] After the spray treatment, the iron substrate is cleaned with deionized water, and the temperature of the deionized water is 55°C;

[0141] Carry out high-temperature degreasing treatment on the iron substrate, the treatment temperature is 350°C, and the treatment time is 10 minutes;

[0142] The aluminum oxide paint is sprayed on the inner and outer walls of the iron substrate by plasma spraying, the spraying distance is 120mm, the spraying power is 80W, the spraying current is 580A, the powder feeding rate is 20g / min, and the flow rate of the working gas Ar 40L / min, auxiliary gas H 2 The flow rate is 2L / min, and the film thickness of the first aluminum oxide layer and the second aluminum oxide layer is 80 μm;

[0143] Non-stick coating spraying: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com