Joint Replacement Prosthesis

A joint replacement and prosthesis technology, applied in the direction of prosthesis, joint implants, joint implants, etc., can solve the problem of weak coating, failure of implanted prosthesis without consideration of peeling of the layer from the polymer substrate, Implanted prosthesis and bone tissue are not firmly connected to achieve the effect of avoiding fluid accumulation and inflammation, light weight, and improving the degree of integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

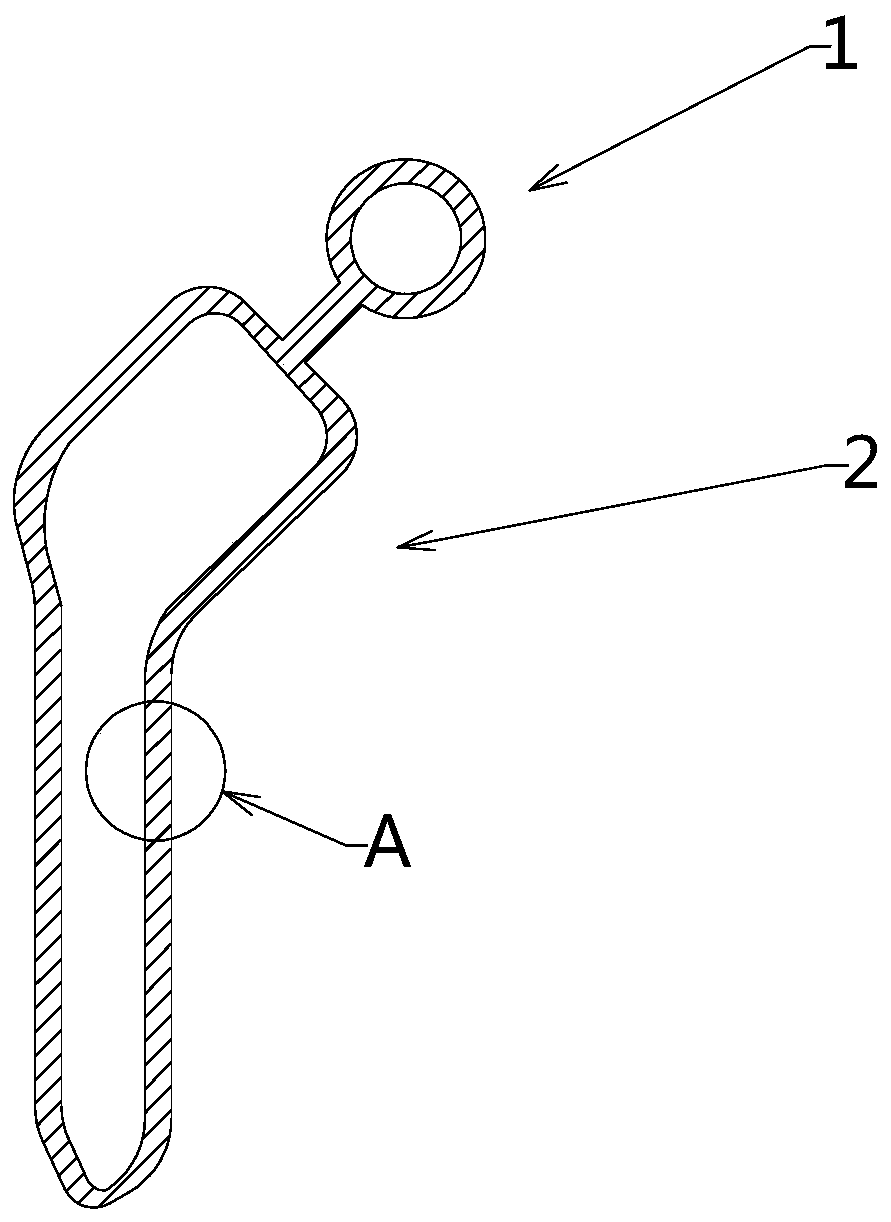

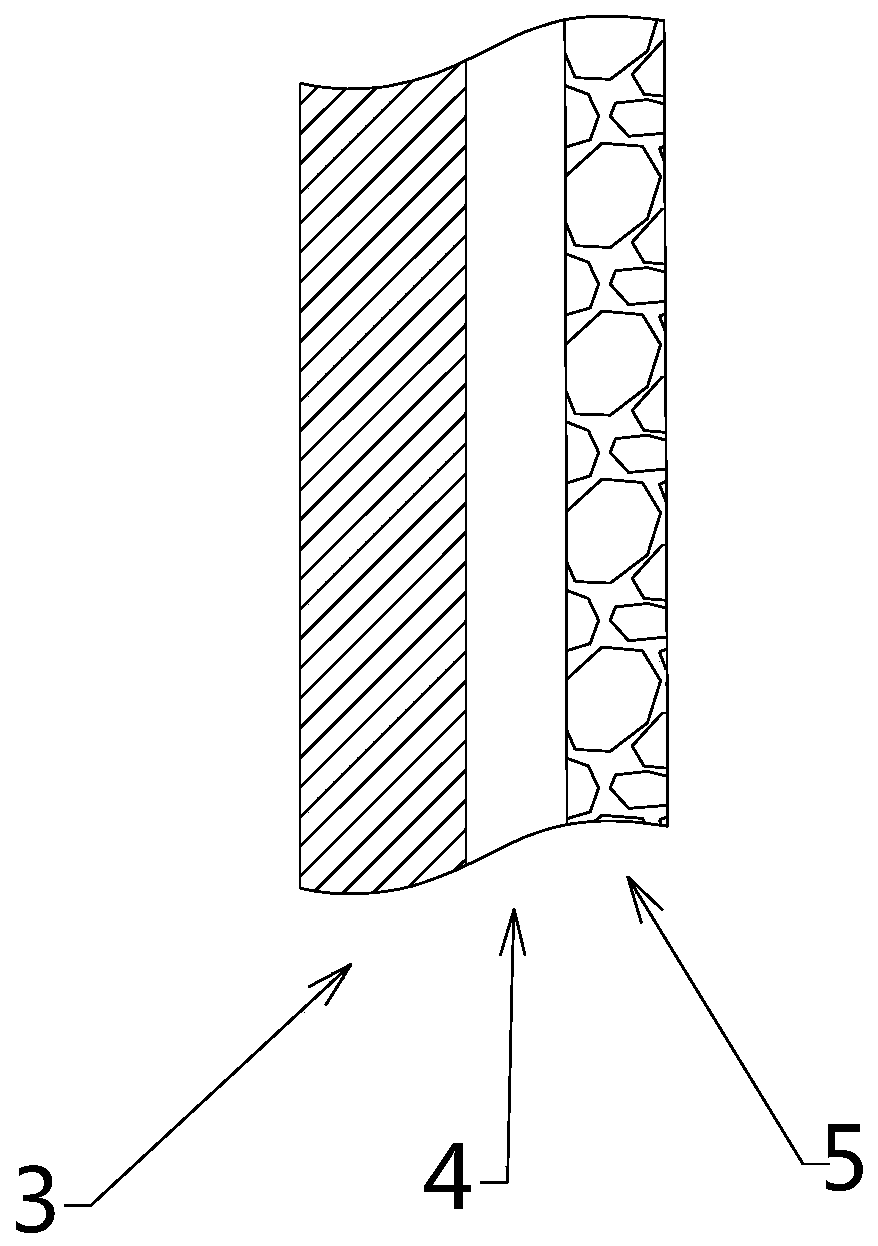

[0030] This embodiment shows the joint replacement prosthesis with non-degradable metal layer 3 and degradable metal layer 4 and its preparation method.

[0031] see figure 1 , the joint replacement prosthesis has a prosthesis head 1 and a prosthesis lower part 2 connected as one, the prosthesis head 1 is in the natural shape of a bone end, the prosthesis lower part 2 is rod-shaped, and the prosthesis Both the body head 1 and the lower part of the prosthesis 2 are hollow structures made of non-degradable polymer material 3 . The hollow structure made of the non-reducible polymer material 3 uses polyether ether ketone as the manufacturing material, and is formed by injecting molten polyether ether ketone into a mold of a corresponding shape using a single-screw extruder to obtain a joint replacement prosthesis polymer matrix. The inner wall of the mold has protrusions with a height ranging from 100-120 μm, so that the surface of the polymer matrix has corresponding blind hole...

Embodiment 2

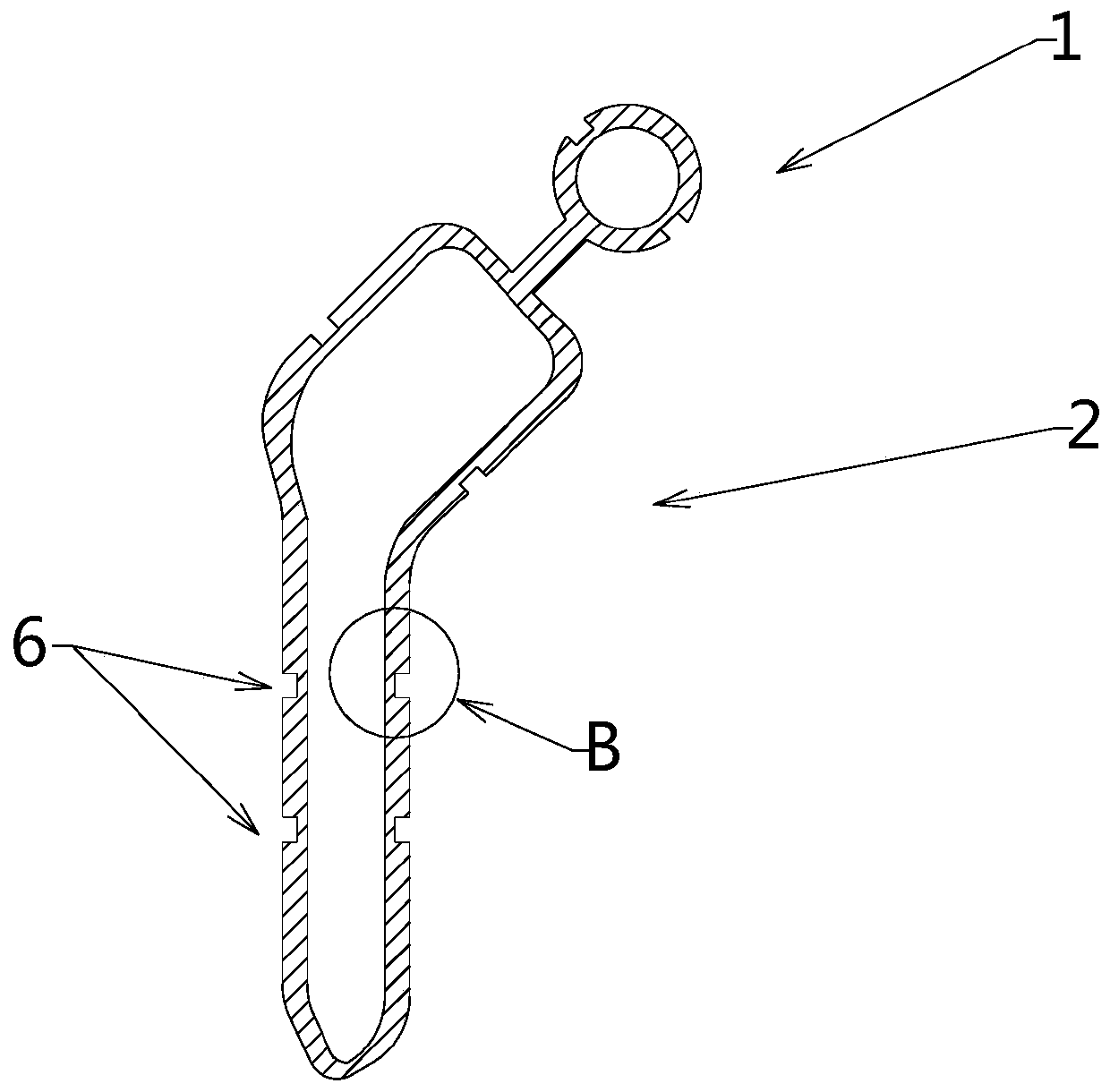

[0035] This example shows a joint replacement prosthesis with a groove 5 filled with a degradable polymer.

[0036] see image 3, using high-density polyethylene as raw material, according to the actual situation of the patient's defective bone restored from the CT image, the hollow matrix with the groove 5 is manufactured by 3D printing. The groove 5 surrounds the prosthesis for one week, with a width of 0.4 mm and a depth of 0.25 mm.

[0037] see Figure 4 , dipping the matrix into the gel of polylactic acid, and stirring the matrix in the gel so that the polylactic acid remains in the groove 5, taking out the matrix and wiping to remove more polylactic acid attached to the surface of the body.

[0038] Subsequently, the groove 5 with polylactic acid was covered with a removable adhesive tape, and then a titanium-zirconium alloy layer with a thickness of 40 μm was covered by physical vapor deposition as the non-degradable metal layer 3 . Referring again to the method show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com