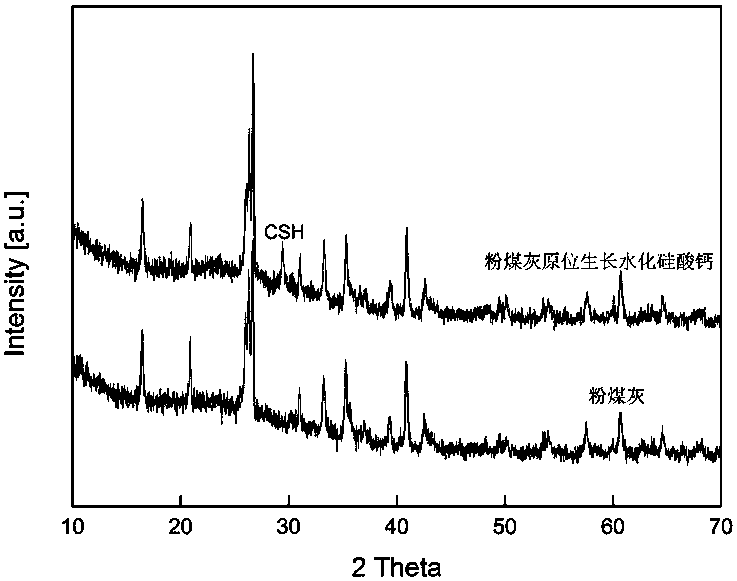

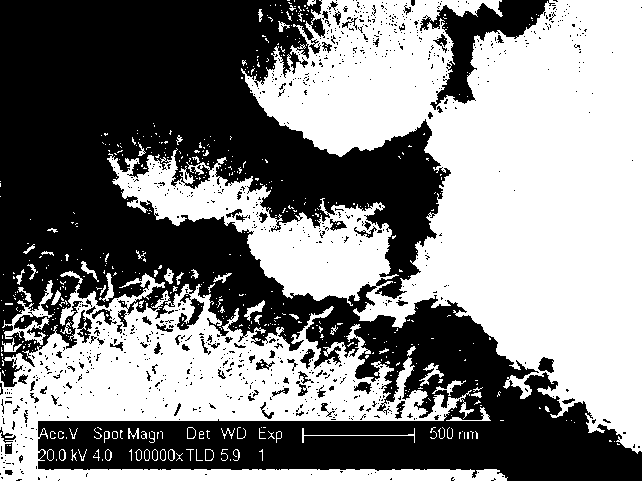

Method for in-situ growth of calcium silicate hydrate on surface of mineral admixture

A technology of mineral admixture and calcium silicate hydrate, which is applied in the direction of silicate, alkaline earth metal silicate, etc., to achieve the effect of improving dispersion uniformity, improving early strength and later strength, and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for in-situ growth of calcium silicate hydrate on the surface of a mineral admixture, comprising the following steps:

[0024] (1) Alkali erosion: first prepare 1000ml of sodium metasilicate nonahydrate aqueous solution with a silicon ion molar concentration of 0.1mol / L, then add 100g of fly ash to it, and stir for 6 hours to obtain a fly ash slurry;

[0025] (2) Chemical co-precipitation reaction: Continue to stir the fly ash slurry obtained in step (1), and prepare 1000ml of calcium acetate aqueous solution with a calcium ion molar concentration of 0.1mol / L, and then add the calcium acetate solution dropwise to the fly ash slurry , The dropping rate is 300ml / min. After the dropwise addition was completed, the stirring was continued for 60 min. Suction filtration and washing are then carried out until the pH value of the filtrate is less than 8. Finally, vacuum-dry at 60° C. to constant weight to obtain calcium silicate hydrate grown in situ on the surface o...

Embodiment 2

[0027] A method for in-situ growth of calcium silicate hydrate on the surface of a mineral admixture, comprising the following steps:

[0028] (1) Alkali erosion: first prepare 1000ml of sodium metasilicate pentahydrate aqueous solution with a silicon ion molar concentration of 0.25mol / L, and then

[0029] 100g of fly ash was added thereto, and stirred for 3 hours to obtain the fly ash slurry;

[0030] (2) Chemical co-precipitation reaction: continue to stir the fly ash slurry obtained in step (1), and prepare 1000ml of calcium ion friction

[0031] A calcium acetate aqueous solution with a concentration of 0.25mol / L is then added dropwise to the fly ash slurry at a rate of 100ml / min. After the dropwise addition was completed, the stirring was continued for 120 min. Suction filtration and washing are then carried out until the pH value of the filtrate is less than 8. Finally, vacuum-dry at 60° C. to constant weight to obtain calcium silicate hydrate grown in situ on the sur...

Embodiment 3

[0033] A method for in-situ growth of calcium silicate hydrate on the surface of a mineral admixture, comprising the following steps:

[0034] (1) Alkali erosion: first prepare 1000ml of sodium silicate aqueous solution with a silicon ion molar concentration of 0.5mol / L, and then

[0035] Add 100g of fly ash and stir for 3 hours to obtain the fly ash slurry;

[0036] (2) Chemical co-precipitation reaction: continue to stir the fly ash slurry obtained in step (1), and prepare 1000ml of calcium ion friction

[0037] A calcium acetate solution with a concentration of 0.5mol / L is added dropwise to the fly ash slurry at a rate of 100ml / min. After the dropwise addition was completed, the stirring was continued for 60 min. Suction filtration and washing are then carried out until the pH value of the filtrate is less than 8. Finally, vacuum-dry at 60° C. to constant weight to obtain calcium silicate hydrate grown in situ on the surface of fly ash.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com