Anti-aging and antibacterial PE (Polyethylene) water service pipe

A water supply pipe and anti-aging technology, applied in the field of pipelines, can solve the problems of complex storage environment, shortened service life, decline, etc., and achieve the effect of low energy consumption and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3、 comparative example 1-3

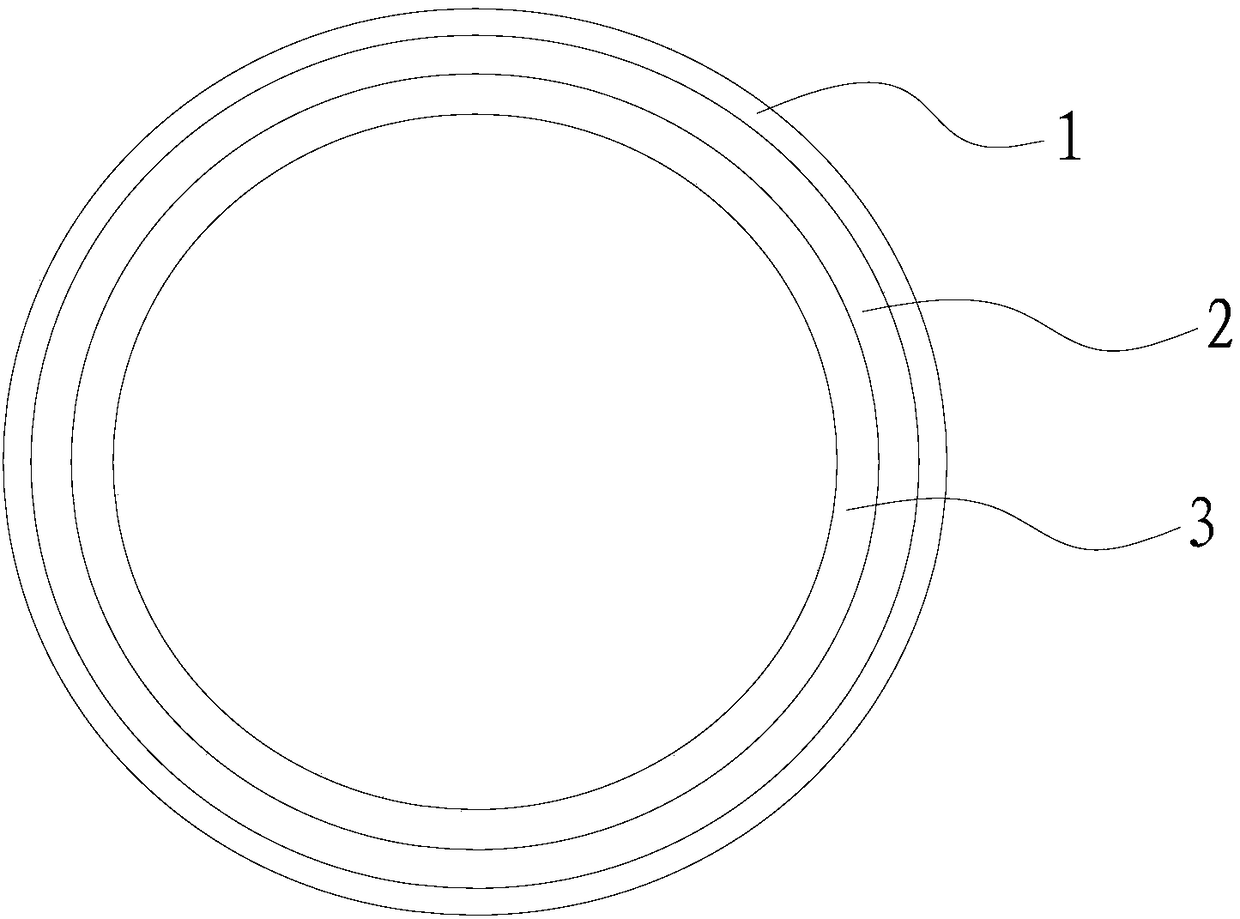

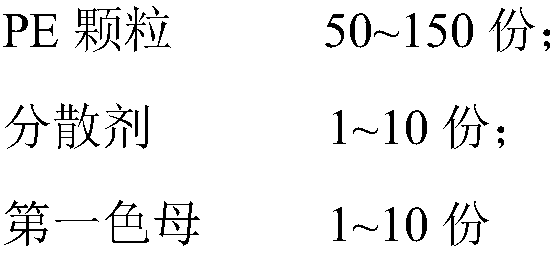

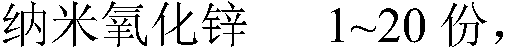

[0029] Embodiment 1-3 provides a kind of anti-aging antibacterial PE water supply pipe respectively, and their structure is as follows figure 1 As shown, the inner layer 3, the middle layer 2 and the outer layer 1 are arranged sequentially from the inside to the outside. The inner layer 3, the middle layer 2 and the outer layer 1 are formed by three-layer co-extrusion. The raw material components of each layer are shown in Table 1. Comparative examples 1-3 provide a kind of PE water supply pipe respectively; Wherein, the inner layer of comparative example 1 does not contain nano-zinc oxide, the outer layer of comparative example 2 does not contain hindered amine free radical scavenger, and the inner layer of comparative example 3 The hindered amine free radical scavenger contained in the outer layer is not a mixture of Hals622 and Hals944, but light stabilizer 770.

[0030] The raw material formula of anti-aging antibacterial PE water supply pipe in the embodiment 1-3 of table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com