A kind of Kyoho rosé wine and its brewing process

A technology for rosé wine and Kyoho grapes, which is applied in the preparation of wine, alcoholic beverages, biochemical equipment and methods, etc., can solve problems such as less research on rosé wine technology, and achieve long-term development, soft taste and bright color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

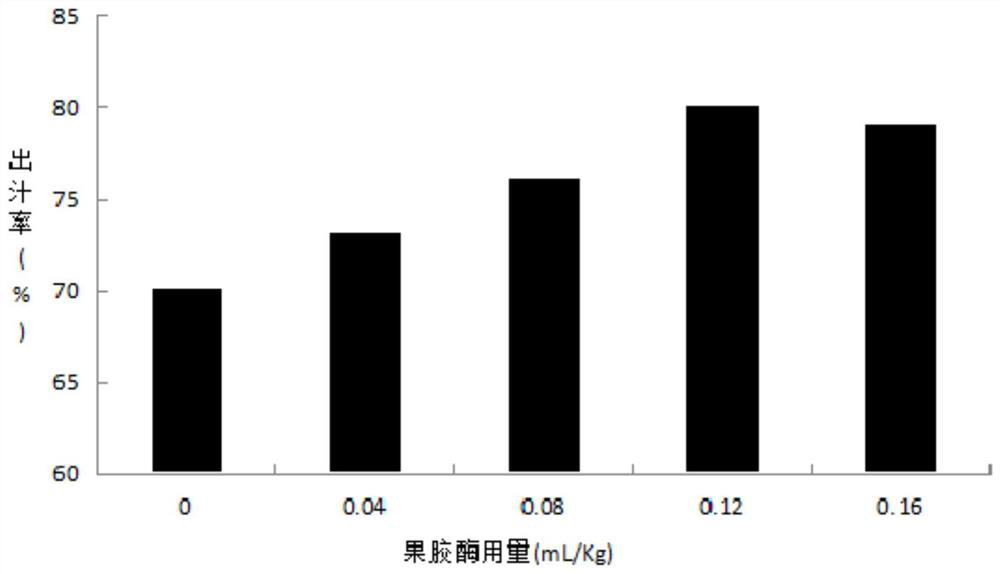

[0028] Experimental Example 1 Effect of Pectinase Addition Amount on Juice Yield

[0029] Select fresh, ripe Kyoho grapes with consistent color and a sugar content above 17°Bx to remove rotten and moldy fruits. Weigh 5 parts of Kyoho grapes, 500g each, break into grape pulp, add 0, 0.04mL / kg, 0.08mL / kg, 0.12mL / kg and 0.16mL / kg pectinase to hydrolyze for 30min, and detect the juice yield. The result is as figure 1 shown. When the amount of pectinase added is 0-0.12mL / kg, the juice yield has an obvious increasing trend. When the amount of pectinase added is 0.08mL / kg and 0.16mL / k, the grape juice yield is higher, 76% and 79%. %, the juice yield was the highest when the addition amount was 0.12mL / kg, reaching 80%. Therefore, the addition amount of pectinase is preferably 0.08-0.16mL / kg.

experiment example 2

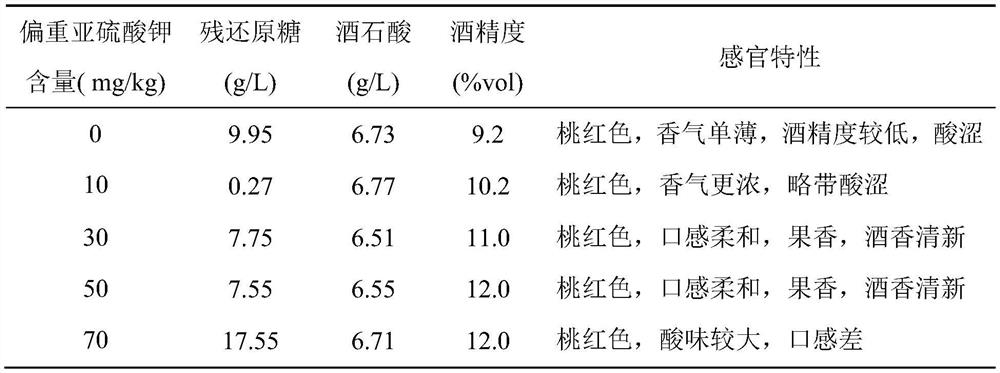

[0030] Experimental Example 2 Effect of Addition of Potassium Metabisulfite on Wine Fermentation

[0031] (1) Sorting: Select fresh, ripe Kyoho grapes with consistent chroma and sugar content above 17°Bx, and remove rotten and moldy fruits. Weigh 5 parts respectively, each 500g.

[0032] (2) Crushing: Soak the sorted Kyoho grapes in water to remove dust respectively, dry them naturally, remove grape stems and grape seeds, crush pulp and pericarp, and obtain grape pulp mixed with pomace.

[0033] (3) Dipping fermentation: 0, 10 mg / kg, 30 mg / kg, 50 mg / kg and 70 mg / kg of potassium metabisulfite were added to 5 portions of grape pulp respectively, and allowed to stand for 2 hours. Add 0.12mL / kg pectinase, and enzymatically hydrolyze for 30min. Add sucrose to bring the initial brix of the grape syrup to 26°Bx. Add 0.02% wine active dry yeast RW, mix well, soak and ferment in a constant temperature incubator at 24° C. for 10 days to obtain preliminary fermented wine.

[0034] (4...

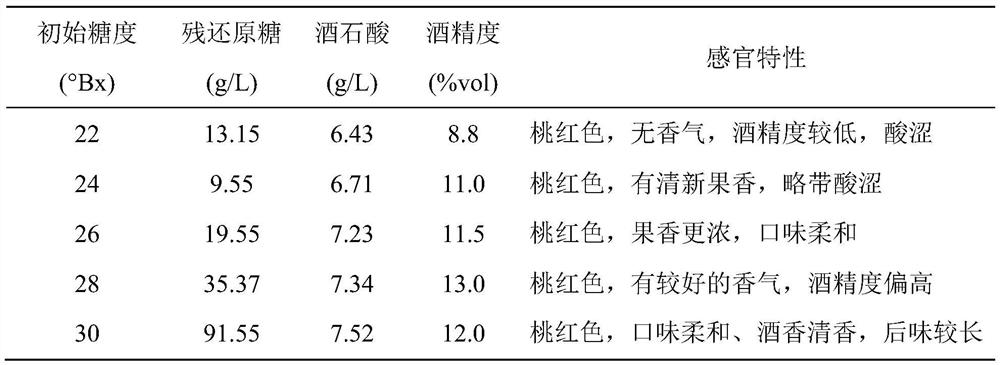

experiment example 4

[0048] Experimental Example 4 Effect of Yeast Inoculum on Wine Fermentation

[0049] (1) Sorting: Select fresh, ripe Kyoho grapes with consistent chroma and sugar content above 17°Bx, and remove rotten and moldy fruits. Weigh 5 parts respectively, each 500g.

[0050] (2) Crushing: Soak the sorted Kyoho grapes in water to remove dust respectively, dry them naturally, remove grape stems and grape seeds, crush pulp and pericarp, and obtain grape pulp mixed with pomace.

[0051] (3) Dipping fermentation: Add 30 mg / kg of potassium metabisulfite to 5 portions of grape juice respectively, and let stand for 2 hours. Add 0.12mL / kg pectinase, and enzymatically hydrolyze for 30min. Add sucrose again, make the initial brix of grape syrup reach 26 ° Bx. Then add 0, 0.01%, 0.02%, 0.03% and 0.04% wine active dry yeast RW respectively, mix well, soak and ferment for 10 days in a constant temperature incubator at 24°C to obtain preliminary fermented wine.

[0052] (4) Separation: The wines...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com