High vacuum winding type capacitor coating machine

A winding-type coating machine technology, which is applied in the field of coating machines, can solve the problems of affecting normal use, poor adhesion of the base film, inconvenient adjustment of the pressure of the base film, etc., and achieves the effect of strong practicability and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

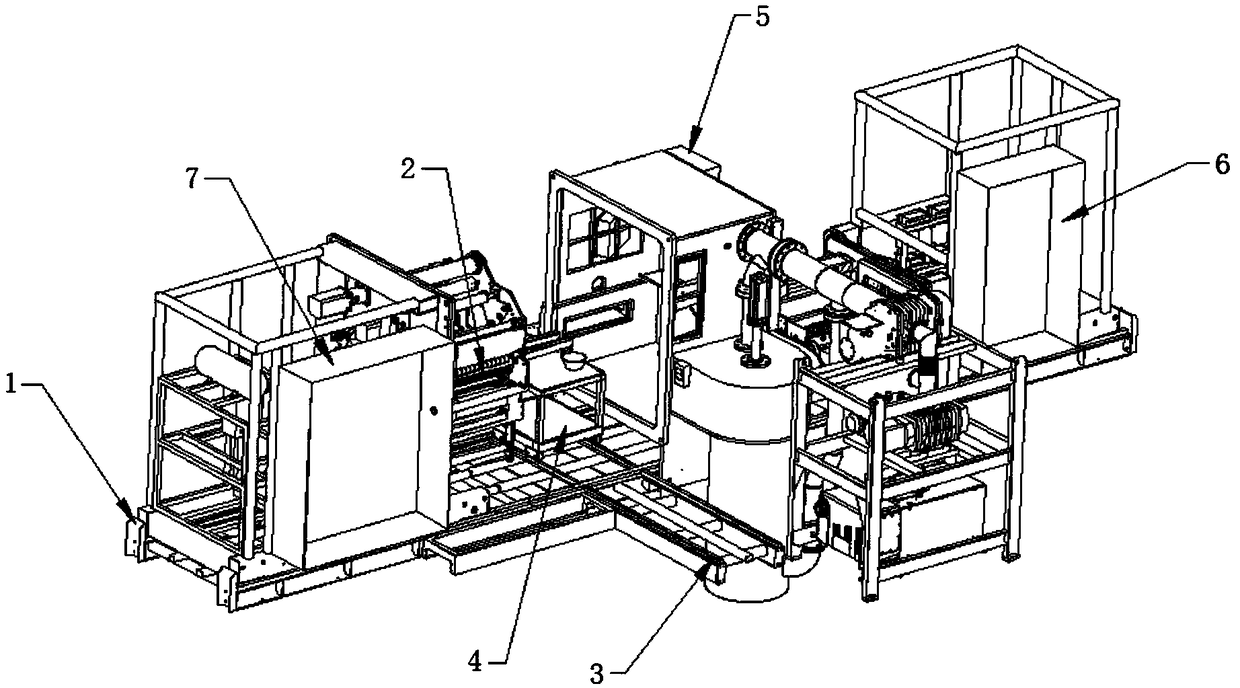

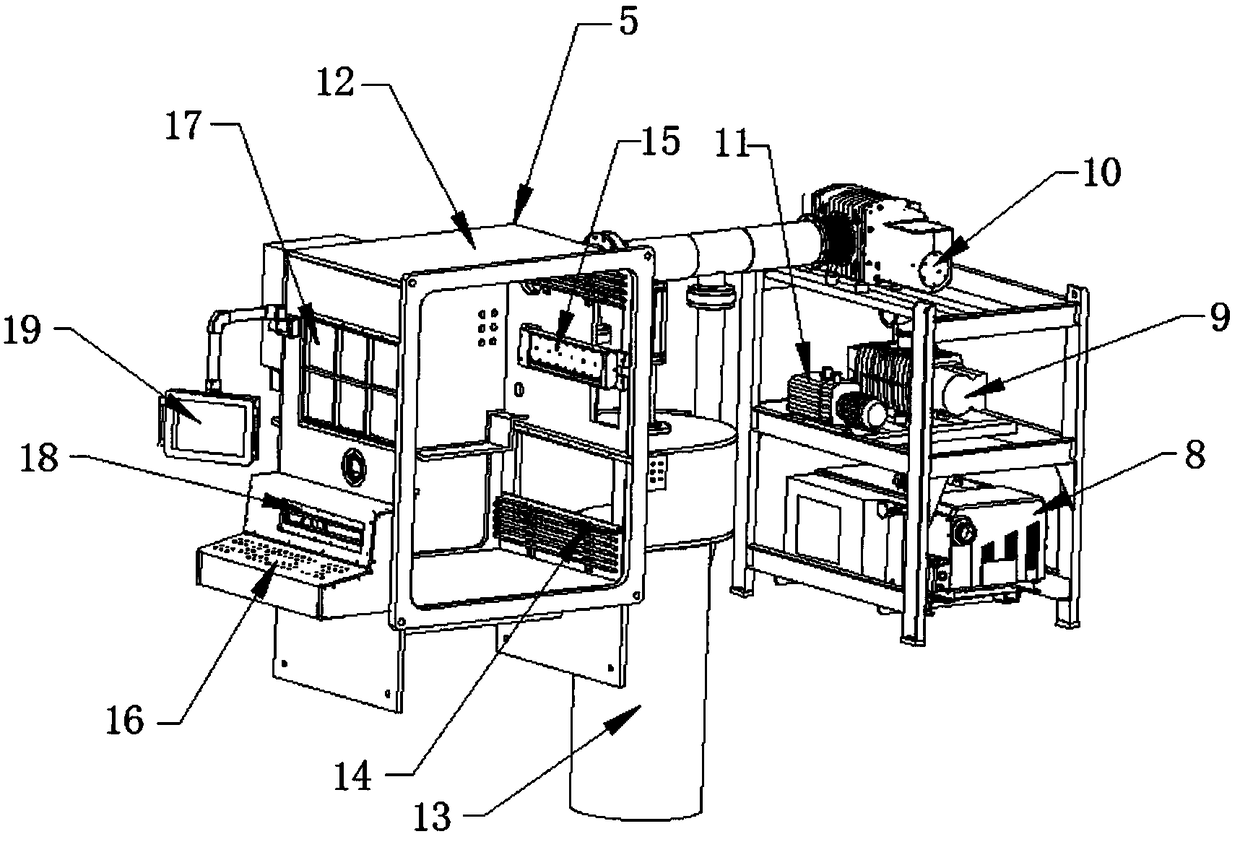

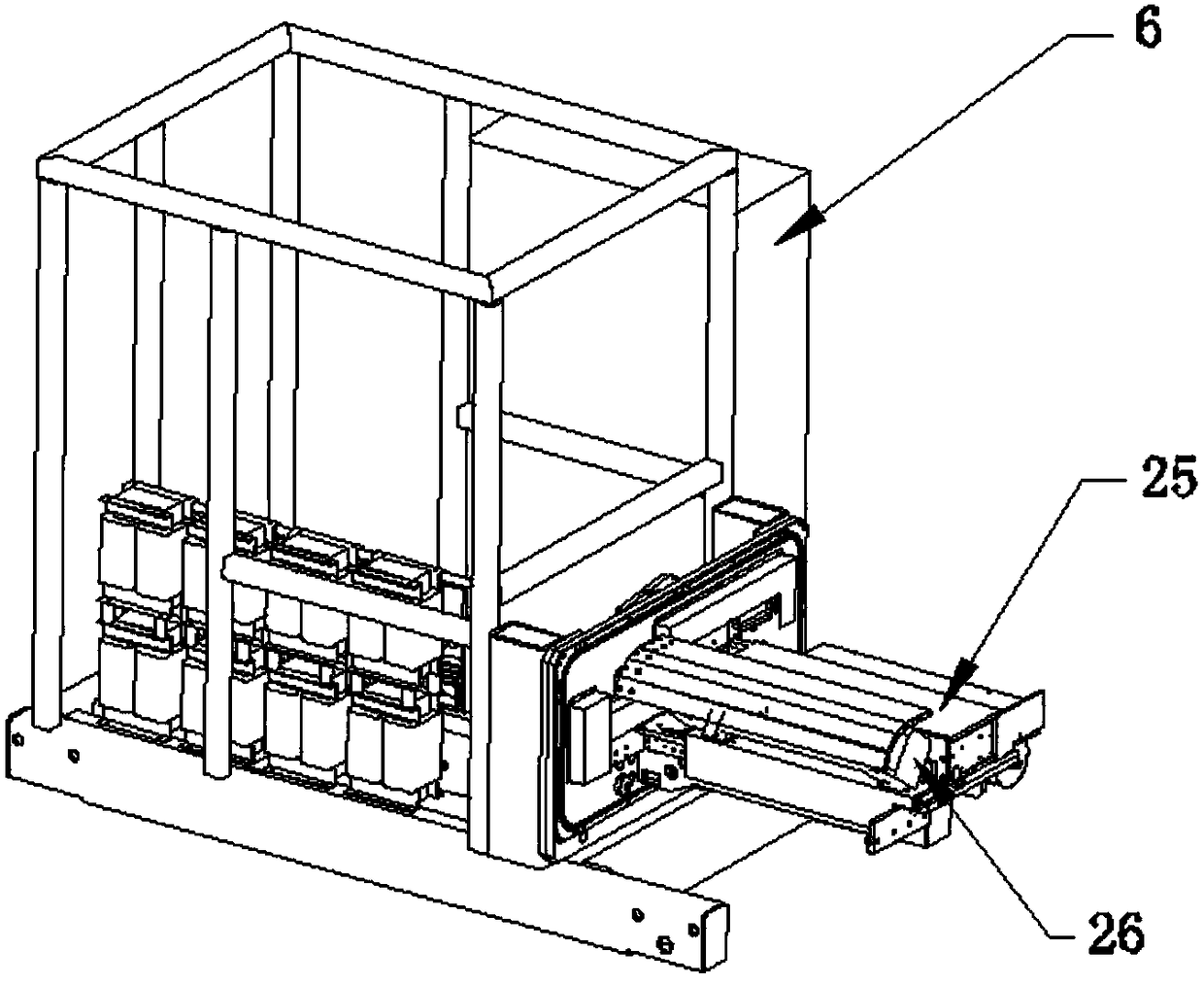

[0024] Such as Figure 1-4 As shown, the present invention provides a high-vacuum winding-type capacitor coating machine, comprising a main rail 1 of the equipment, the top of the main rail 1 of the equipment is equipped with a coiling system electric cabinet 7, and one side of the coiling system electric cabinet 7 is provided with an oil Evaporation system 2, one side of the oil evaporation system 2 is provided with a service cart 4, the bottom of the service cart 4 is provided with a service cart guide rail 3, one side of the service cart 4 is provided with a vacuum system electric cabinet 5, the vacuum system electric cabinet 5 An evaporation system electrical cabinet 6 is arranged on one side, and a diffusion pump 13 is installed at the bottom of the vacuum system electrical cabinet 5. A vacuum chamber 12 is installed on the top side of the diffusion pump 13, and a cold well is installed on the inner bottom side of the vacuum chamber 12. Steel pipe 14, the top of the cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com