Method for growing sapphire crystal by kyropoulos method

A technology of sapphire crystal and foaming method, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of reducing the quality of sapphire crystal and increasing the bubbles of steamed bread, so as to alleviate the bubbles of steamed bread and alleviate the problems of bubbles. Growth, Mitigation Formation and Growth Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

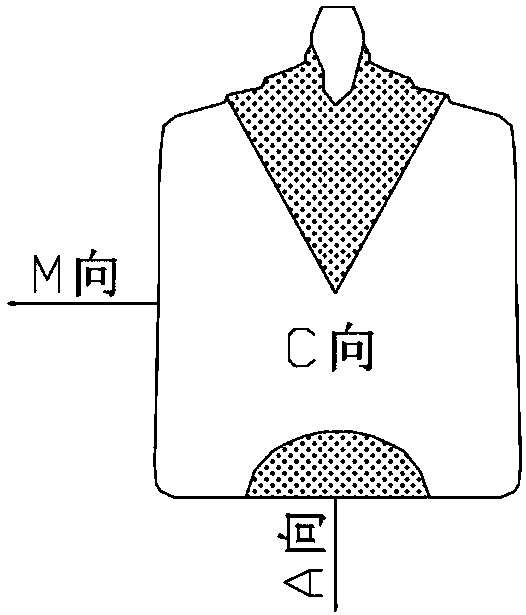

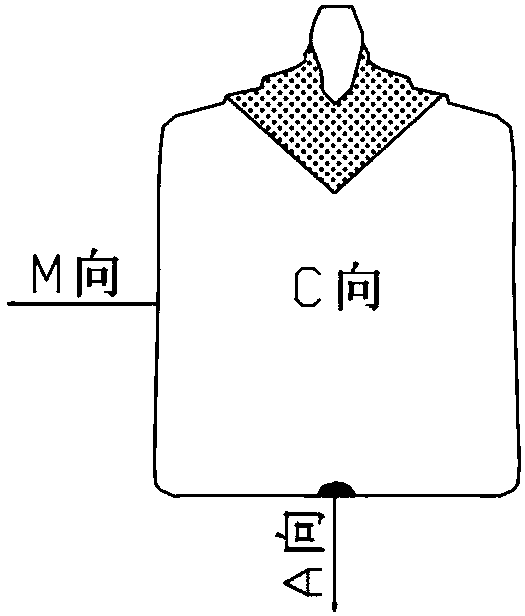

[0045] This application provides a method for growing sapphire crystals by the Kyropoulos method. The method includes several stages of charging, heating and chemicalizing materials, seeding, expanding shoulder growth, equal diameter growth, ending growth, extraction, and cooling. The specific implementation The method includes the following steps:

[0046] S101: Clean the furnace and insulation layer with alcohol, dust-free cloth, copper wire brush, industrial vacuum cleaner, etc., put the alumina raw material with a purity of 5N into the crucible in a special clean room, and pack it with clean plastic cloth for replacement.

[0047] S102: Put the crucible full of raw materials into the furnace, install the A-direction seed crystal on the seed chuck, and screw it on the seed rod, complete the centering of the seed rod, close the furnace, vacuumize and check for leaks.

[0048] S103: According to different thermal fields and raw materials, determine the material chemical proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com