Noise-proof telephone booth metal shell capable of automatically adjusting temperature and manufacturing method thereof

A technology for metal shells and telephone booths, which is applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., which can solve the problem of affecting call quality and voice clarity of callers, poor noise isolation effect, and failure to meet call requirements and other problems, to achieve the effect of small change in latent heat of phase change, stable size, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

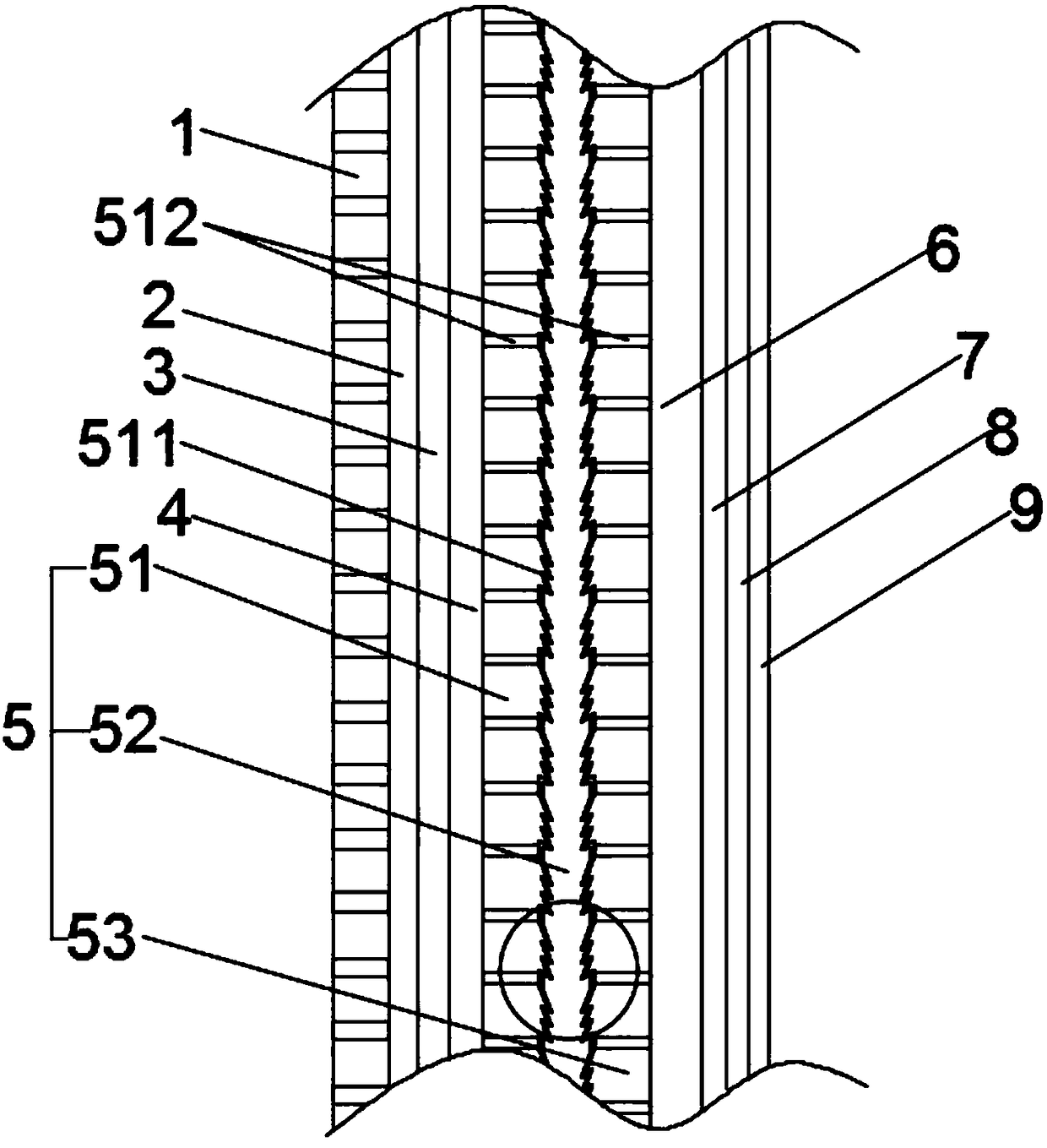

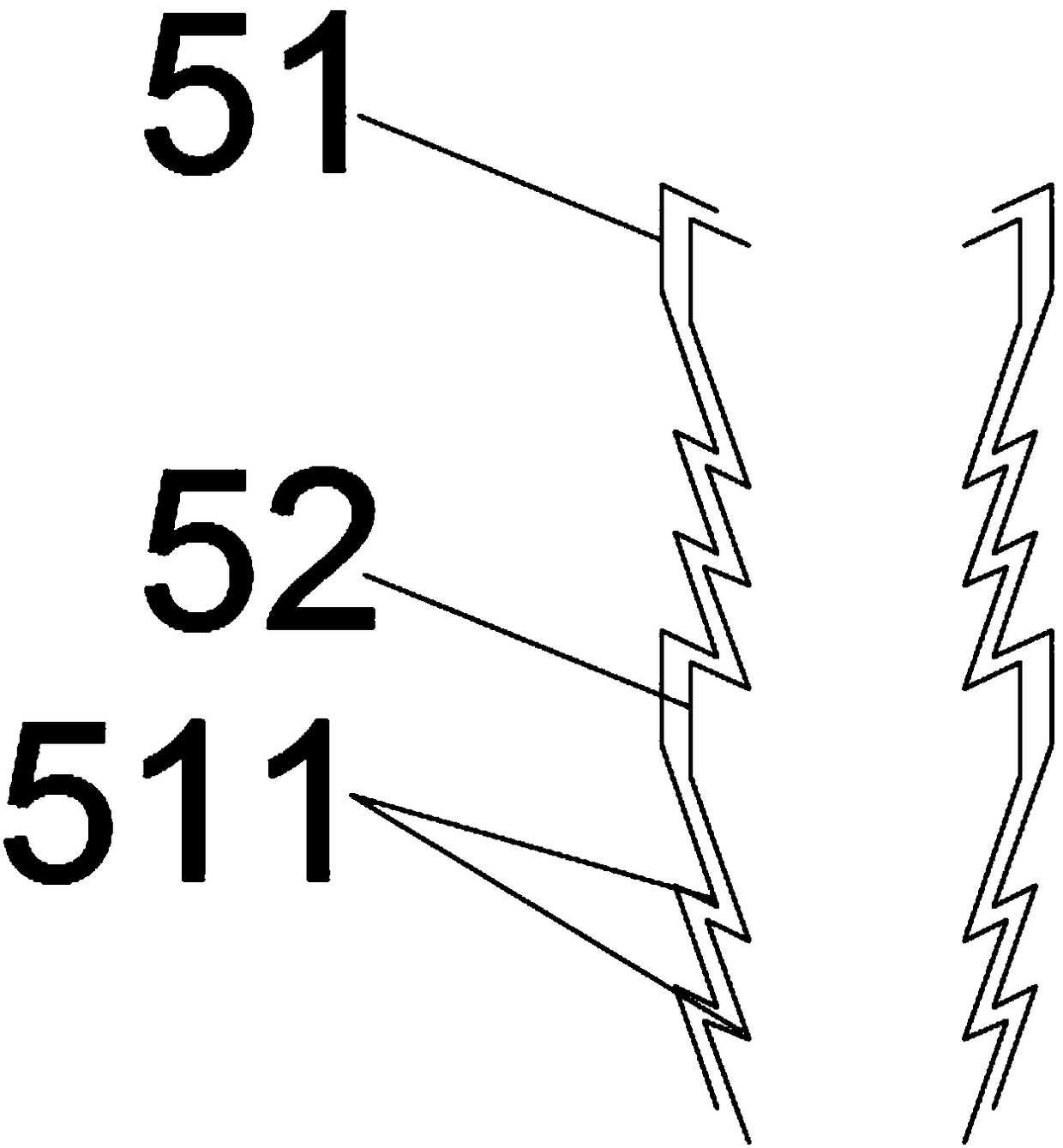

[0023] Such as Figure 1-2 As shown, the metal casing of an automatic temperature-regulating noise-proof telephone booth described in this embodiment includes an arched top cover, bottom left and right side sealing plates and a back sealing plate, and the arched top cover, bottom left and right side sealing plates Both the sound-absorbing and noise-reducing metal plate structure are adopted for the back-sealing plate, and the sound-absorbing and noise-reducing metal plate structure includes an inner metal plate layer 1, a heat conduction layer 2, a heat conduction material layer 3, a phase change material layer Noise layer 5, outer metal plate layer 6 and 8 layers of decorative protection, the sound-absorbing and noise-reducing layer 5 includes an inner sound-absorbing plate layer 51, a sound-absorbing cotton layer 52, and an outer sound-absorbing plate layer 53 from the inside to the outside, and the inner metal plate Layer 1, heat conduction layer 2, heat conduction material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com