Acid mist inhibitor performance test method

A technology of acid mist inhibitor and test method, applied in the direction of analysis materials, instruments, etc., can solve the problem of difficulty in evaluating the performance of acid mist inhibitor, and achieve the effects of accurate and reliable measurement results, small size and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

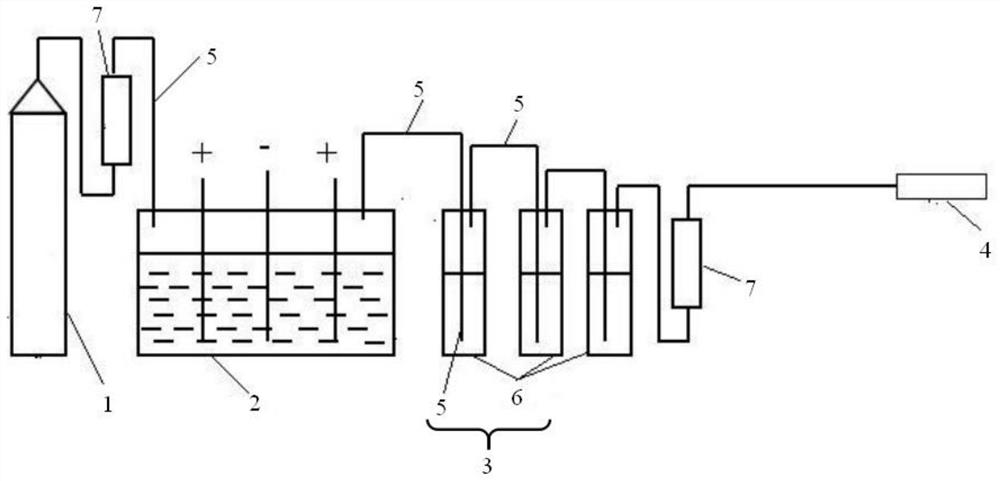

[0017] Such as figure 1 The acid mist testing device shown is mainly composed of a gas source 1 , an electrowinning tank 2 , an acid mist absorption unit 3 and a vacuum pump 4 connected in sequence through a gas pipe 5 . The electrowinning cell 2 is sealed with a cover and kept warm in a water bath. The acid mist absorbing unit 3 includes 3 water containers 6 connected in series, and each water container 6 is also connected by a gas pipe 5, and the gas pipe 5 of the air intake in the water container 6 stretches under the water surface in the water container 6, to the water container 6. The end of the trachea 5 of the external exhaust of the water container 6 is above the water surface. A gas flow meter 7 is installed on the gas pipe 5 between the gas source 1 and the electrowinning tank 2, and on the gas pipe 5 between the acid mist absorption unit 3 and the vacuum pump 4. The gas flow meter 7 has a valve to adjust the gas flow . The gas comes out from the gas source 1 and ...

Embodiment 2

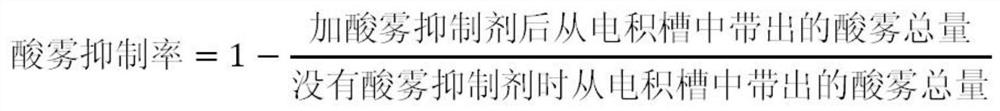

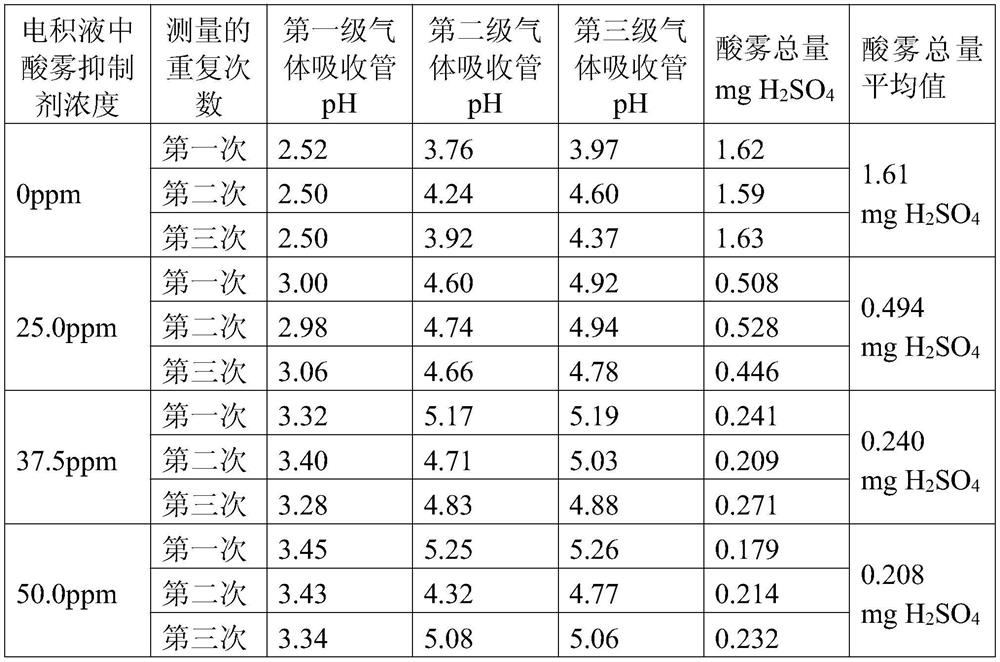

[0022] Example 2 Performance Test of Acid Mist Inhibitor

[0023] Utilize the acid mist test device of Example 1 to test the performance of the acid mist inhibitor.

[0024] Among them, the size of the electrowinning tank is: 140 mm * 102 mm * 130 mm, the size of the cathode plate and the anode plate is: 100 mm * 100 mm, the distance between the cathode plate and the anode plate: 40 mm, the amount of electrolytic solution is 1.0 liters, acid The dosage of fog suppressant FS-101 is 0.0250, 0.0375, 0.0500 ml. The vertical distance between the nitrogen inlet of the electrowinning tank cover and the electrowinning liquid surface is 40 mm, the vertical distance between the acid mist outlet of the electrowinning tank cover and the electrowinning liquid surface is 60 mm, and the volume of water in each gas absorption tube is 10 mm. ml. The gas absorption tube can be cooled to 10°C with ice water.

[0025] The initial concentration of copper in the electrolytic solution is 40g / L, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com