Capacitive type online corrosion monitoring device and method

A monitoring device and corrosion monitoring technology, applied in electromagnetic measurement devices, material capacitance, electromagnetic/magnetic depth measurement, etc., can solve the problems of immeasurable losses, high related costs, small hole corrosion, etc., to achieve the type of corrosion, the realization of online Monitoring the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

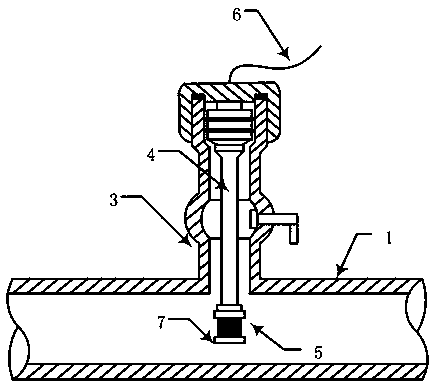

[0058] In this example, figure 1 It is a structural schematic diagram of a capacitive corrosion on-line monitoring device. The capacitive corrosion on-line monitoring device includes a production pipeline 1, an installation seat 3, a corrosion hanging rod 4, a capacitive corrosion coupon 5, a transmission line 6, and a fixed base 7;

[0059] The installation seat 3 is installed on the production pipeline 1, and the upper part is connected with the corrosion hanging rod 4 through threads, the capacitive corrosion hanging piece 5 is installed on the corrosion hanging rod 4, and the bottom of the corrosion hanging rod 4 is threaded with the fixed base 7 connected, the transmission line 6 is connected to the capacitive corrosion coupon 5, and sealed and packaged in the corrosion hanger 4.

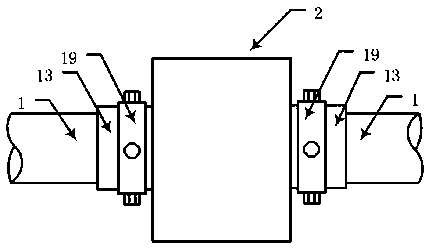

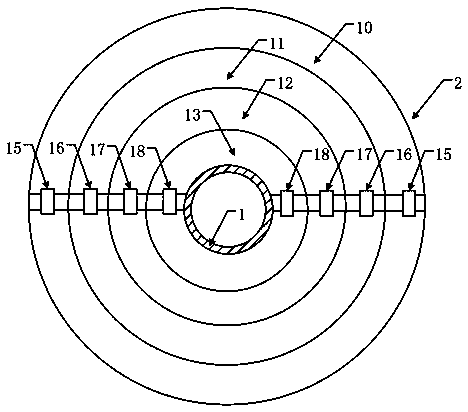

[0060] figure 2 It is a schematic structural diagram of the heat exchange box in the embodiment of the present invention, image 3 It is the left view of the heat exchange box in the embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com