A kind of continuous extrusion equipment for preparing graphene aluminum wire

An extrusion equipment and graphene technology are applied in the field of continuous extrusion equipment for preparing graphene aluminum wires, which can solve problems such as affecting the production efficiency of aluminum wires, limit wire length, and deteriorate material properties, and achieve energy saving and performance stability. Good, good product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A preparation method of graphene / aluminum composite material, the method comprises the following steps:

[0034] (1) Take graphene and -200~400 purpose aluminum alloy powder, graphene accounts for 0.5% of total mass;

[0035] (2) Graphene is ultrasonically dispersed in alcohol solution for 0.5h to obtain graphene / alcohol mixed solution;

[0036] (3) adding the aluminum powder into the graphene / alcohol mixed solution in batches, at a speed of 100r / min, at a temperature of 40°C, and mixing for 2 hours to obtain a semi-solid paste graphene / aluminum mixed powder;

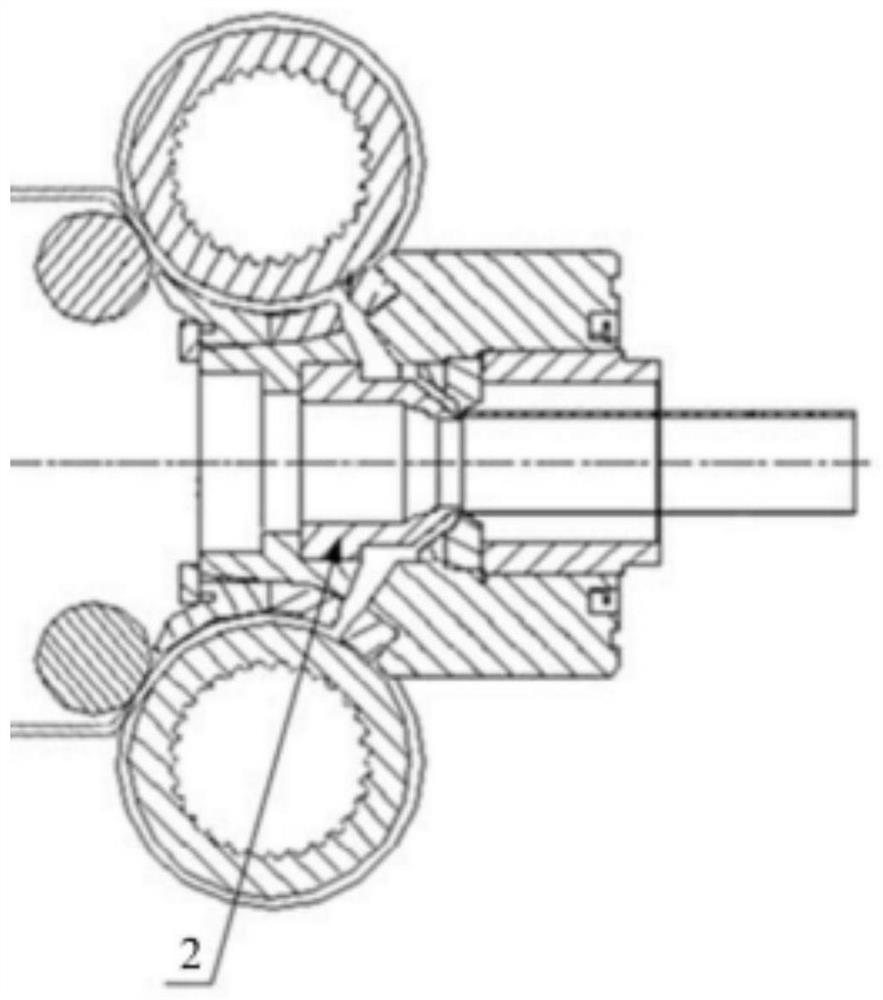

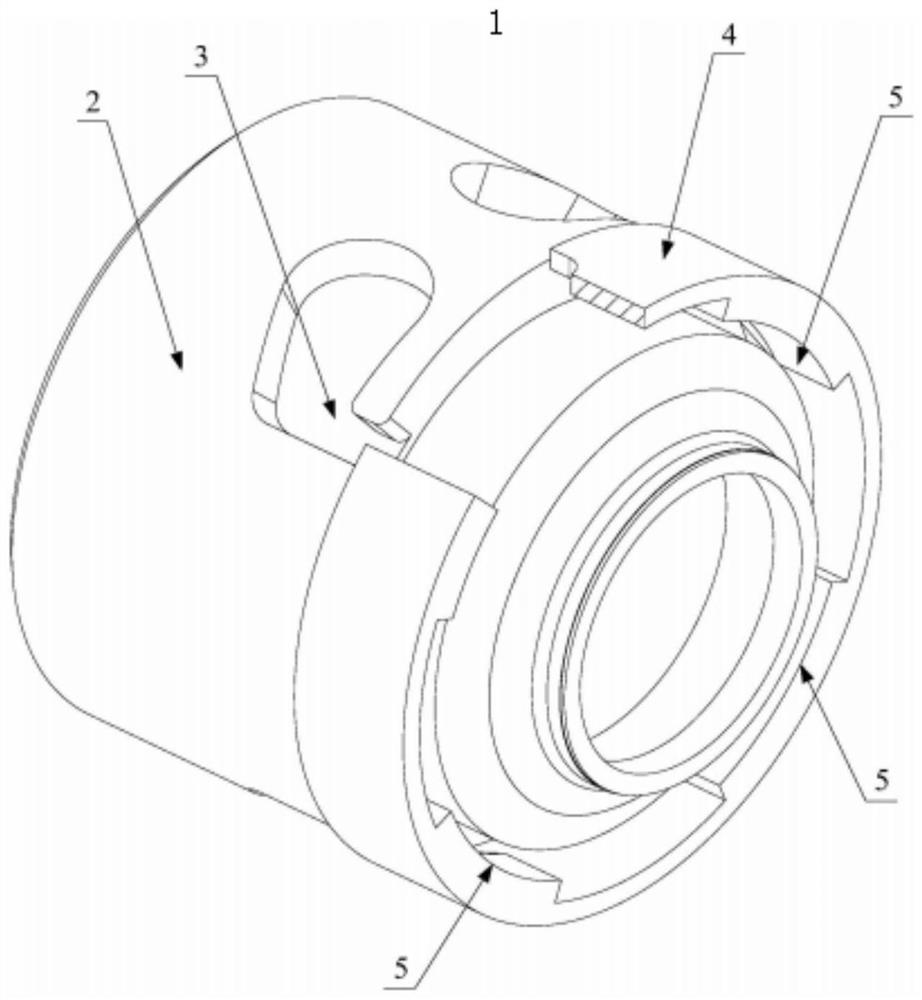

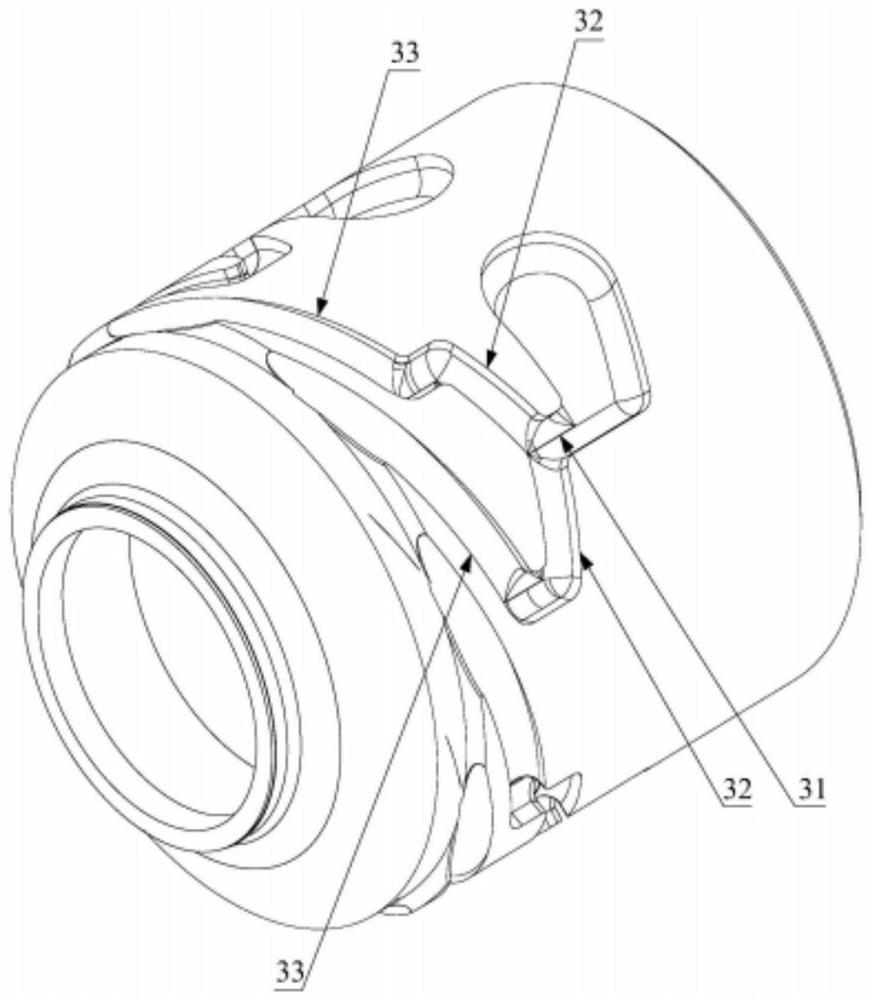

[0037] (4) Place the uniformly mixed graphene / aluminum powder at the feeding place of the continuous extrusion equipment;

[0038] (5) Open the feed valve, and perform dynamic vacuum degassing during the downward flow of the graphene / aluminum mixed powder. The flow rate is 1.0L / min, the heating temperature is 300°C, and the vacuum degree is 2.0×10 -3 Pa;

[0039] (6) Continuously extruding the graphene / aluminu...

Embodiment 2

[0041] A preparation method of graphene / aluminum composite material, the method comprises the following steps:

[0042] (1) Take graphene and -200~400 purpose aluminum alloy powder, graphene accounts for 1.0% of total mass;

[0043] (2) Graphene is ultrasonically dispersed in alcohol solution for 1.0h to obtain graphene / alcohol mixed solution;

[0044] (3) Add the aluminum powder into the graphene / alcohol mixed solution in batches, at a rotating speed of 500r / min, at a temperature of 60°C, and mix for 1h to obtain a semi-solid paste graphene / aluminum mixed powder;

[0045] (4) Place the uniformly mixed graphene / aluminum powder at the feeding place of the continuous extrusion equipment;

[0046] (5) Open the feed valve, and perform dynamic vacuum degassing during the downward flow of the graphene / aluminum mixed powder, with a flow rate of 5.0L / min, a heating temperature of 400°C, and a vacuum degree of 5.0×10 -3 Pa;

[0047] (6) Continuously extruding the graphene / aluminum p...

Embodiment 3

[0049] A preparation method of graphene / aluminum composite material, the method comprises the following steps:

[0050] (1) Take graphene and -200~400 purpose aluminum powder, graphene accounts for 0.7% of total mass;

[0051] (2) Graphene is ultrasonically dispersed in alcohol solution for 1.5h to obtain a mixed solution of graphene and alcohol;

[0052] (3) Add the aluminum powder into the graphene / alcohol mixed solution in batches, at a speed of 250r / min, at a temperature of 50°C, mix for 1.5h to obtain a semi-solid paste graphene / aluminum mixed powder;

[0053] (4) Place the uniformly mixed graphene / aluminum powder at the feeding place of the continuous extrusion equipment;

[0054] (5) Open the feed valve, and perform dynamic vacuum degassing during the downward flow of the graphene / aluminum mixed powder, with a flow rate of 3.5L / min, a heating temperature of 350°C, and a vacuum degree of 3.5×10 -3 Pa;

[0055] (6) Continuously extruding the graphene powder after vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com