Connection structure and method for SiCf/SiC composite pipes

A technology of composite materials and connection methods, which is applied in the direction of connection components, rod connections, mechanical equipment, etc., can solve problems such as the inability to meet the connection requirements of silicon carbide composite materials, poor ductility of silicon carbide composite material pipe fittings, and inability to use connection technology. Achieve the effect of good connection effect, good anti-oxidation performance and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

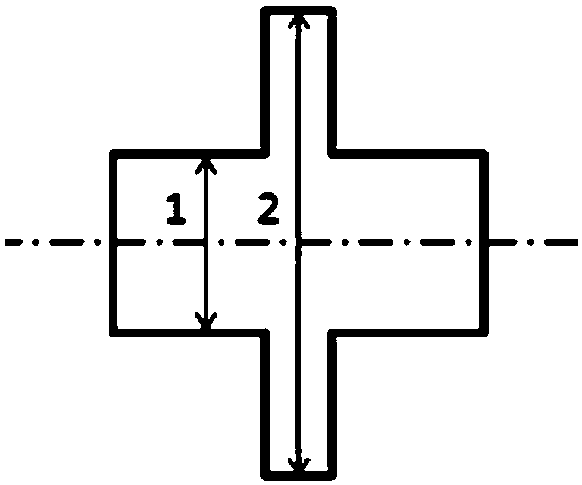

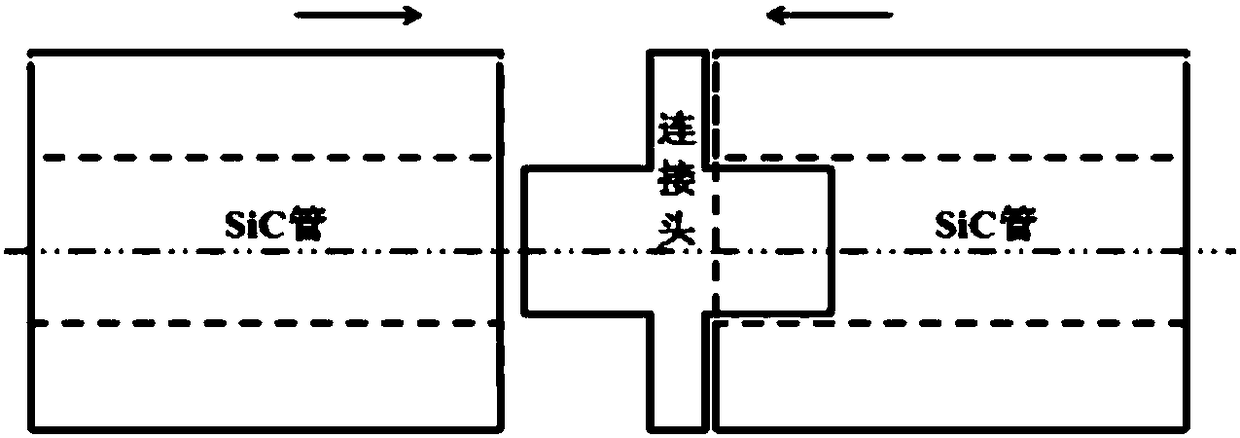

[0051] In this example, the inner diameter of the silicon carbide composite pipe fittings to be connected is 10mm, the outer diameter is 12mm, and the two lengths are both 50mm.

[0052] Step 1, make the connector.

[0053] The pure titanium rod with a titanium purity ≥ 99.99% is machined into a connecting head with a variable-diameter cylindrical structure, the diameter of the head 1 is 9.7 mm, and the diameter of the middle part 2 is 12 mm.

[0054] Step 2, linking agent preparation.

[0055] Put the titanium powder and the silicon carbide powder into the phenolic resin alcohol solvent and mix evenly to obtain the connecting agent. Among them, the atomic ratio of titanium: silicon carbide is 8:1, and the solid content is above 60%; the purity of titanium powder is ≥99.99%, and the particle size is 100um; the purity of silicon carbide powder is ≥99.99%, and the particle size is 15um.

[0056] Step 3, pipe fitting connection.

[0057] Apply the connecting agent evenly at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com