A kind of preparation method of vildagliptin cyclic amidine impurity

A vildagliptin cyclic amidine and impurity technology, applied in the field of medicinal chemistry, can solve the problems of complex process and high cost, and achieve the effects of high yield, reduced research and development costs, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

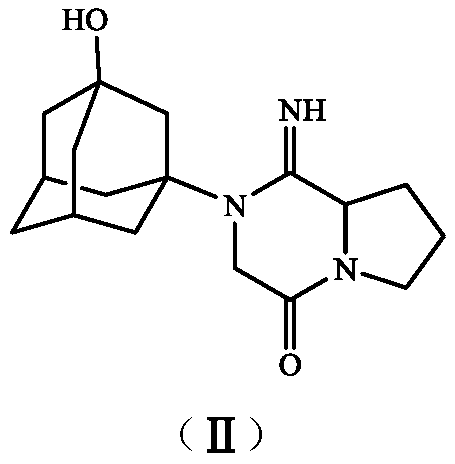

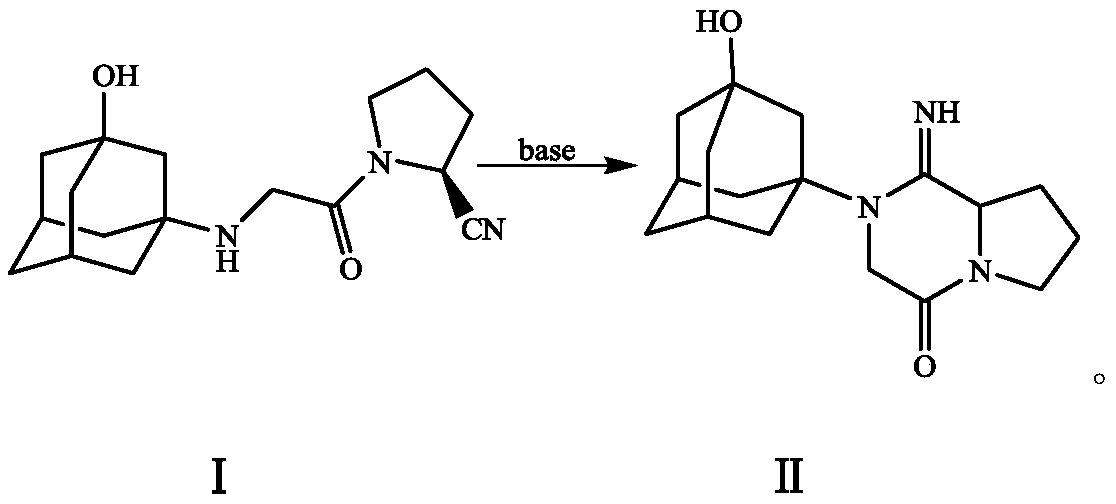

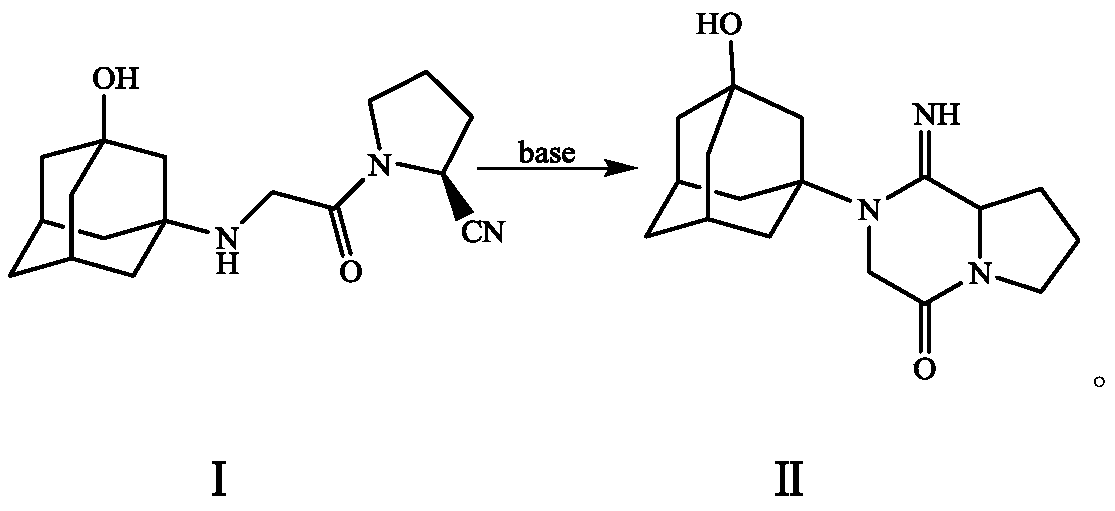

[0024] Embodiment 1: Preparation of vildagliptin cyclic amidine impurity

[0025]

[0026] Add 30.3g vildagliptin (I) (0.1mol) and 200ml ethanol to a 1000ml four-necked bottle equipped with mechanical stirring, condenser, thermometer and heating device, and then add 200ml aqueous solution of 20g sodium hydroxide (0.5mol) , the temperature was raised to 40° C., and the reaction was carried out for 5 hours, and the reaction was completed. Cool to room temperature and filter, evaporate the filtrate to dryness, then add 500ml of a mixed solution of methanol and dichloromethane (methanol:dichloromethane=1:10 (v:v)), stir to dissolve, filter, and evaporate the filtrate to obtain a white solid , which is the degradation impurity (II) of vildagliptin amide, with a yield of 85%.

Embodiment 2

[0027] Embodiment 2: Preparation of vildagliptin cyclic amidine impurity

[0028] Add 30.3g vildagliptin (I) (0.1mol) and 200ml methanol to a 1000ml four-necked bottle equipped with mechanical stirring, condenser, thermometer and heating device, then add 200ml aqueous solution of 28g potassium hydroxide (0.5mol) , the temperature was raised to 60° C., and the reaction was carried out for 5 hours, and the reaction was completed. Cool to room temperature and filter, evaporate the filtrate to dryness, then add 500ml of a mixed solution of methanol and dichloromethane (methanol:dichloromethane=1:10 (v:v)), stir to dissolve, filter, and evaporate the filtrate to obtain a white solid , which is the degradation impurity (II) of vildagliptin amide, with a yield of 80%.

Embodiment 3

[0029] Embodiment 3: Preparation of vildagliptin cyclic amidine impurity

[0030] Add 30.3g vildagliptin (I) (0.1mol) and 200mlDMF in the 1000ml four-necked bottle equipped with mechanical stirring, condenser, thermometer, heating device, add 200ml aqueous solution of 28g potassium hydroxide (0.5mol) again, The temperature was raised to 70° C., and the reaction was completed for 5 hours. Cool to room temperature and filter, evaporate the filtrate to dryness, then add 500ml of a mixed solution of methanol and dichloromethane (methanol:dichloromethane=1:10 (v:v)), stir to dissolve, filter, and evaporate the filtrate to obtain a white solid , which is the degradation impurity (II) of vildagliptin amide, with a yield of 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com