Manufacturing method of mosquito-dispelling LED lamp

An LED lamp and LED filament technology, applied in the field of machinery, can solve the problems of heavy maintenance workload, mosquito bites, low light efficiency, etc., and achieve the effects of shortening processing steps, preventing mosquito bites, and high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

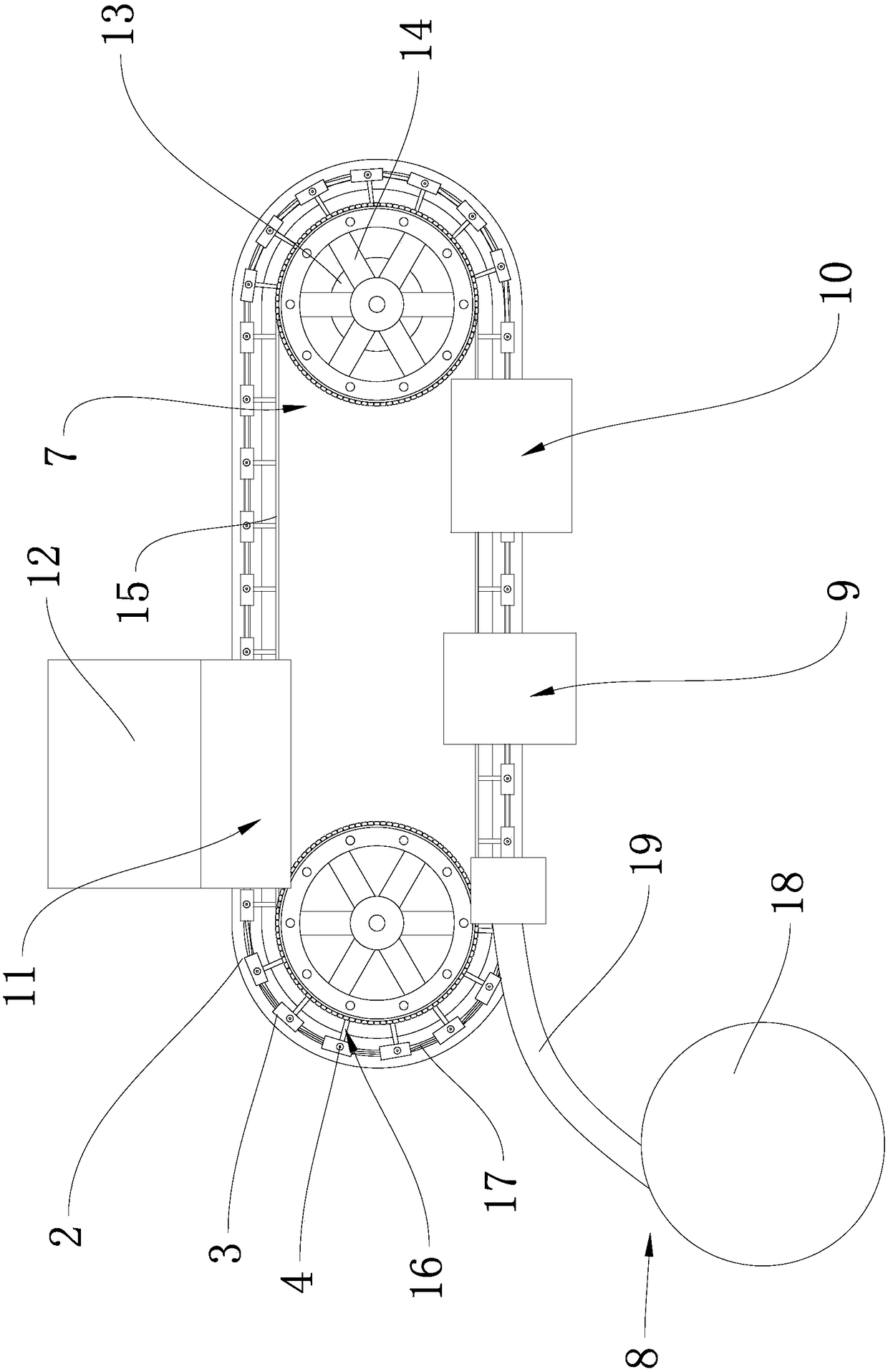

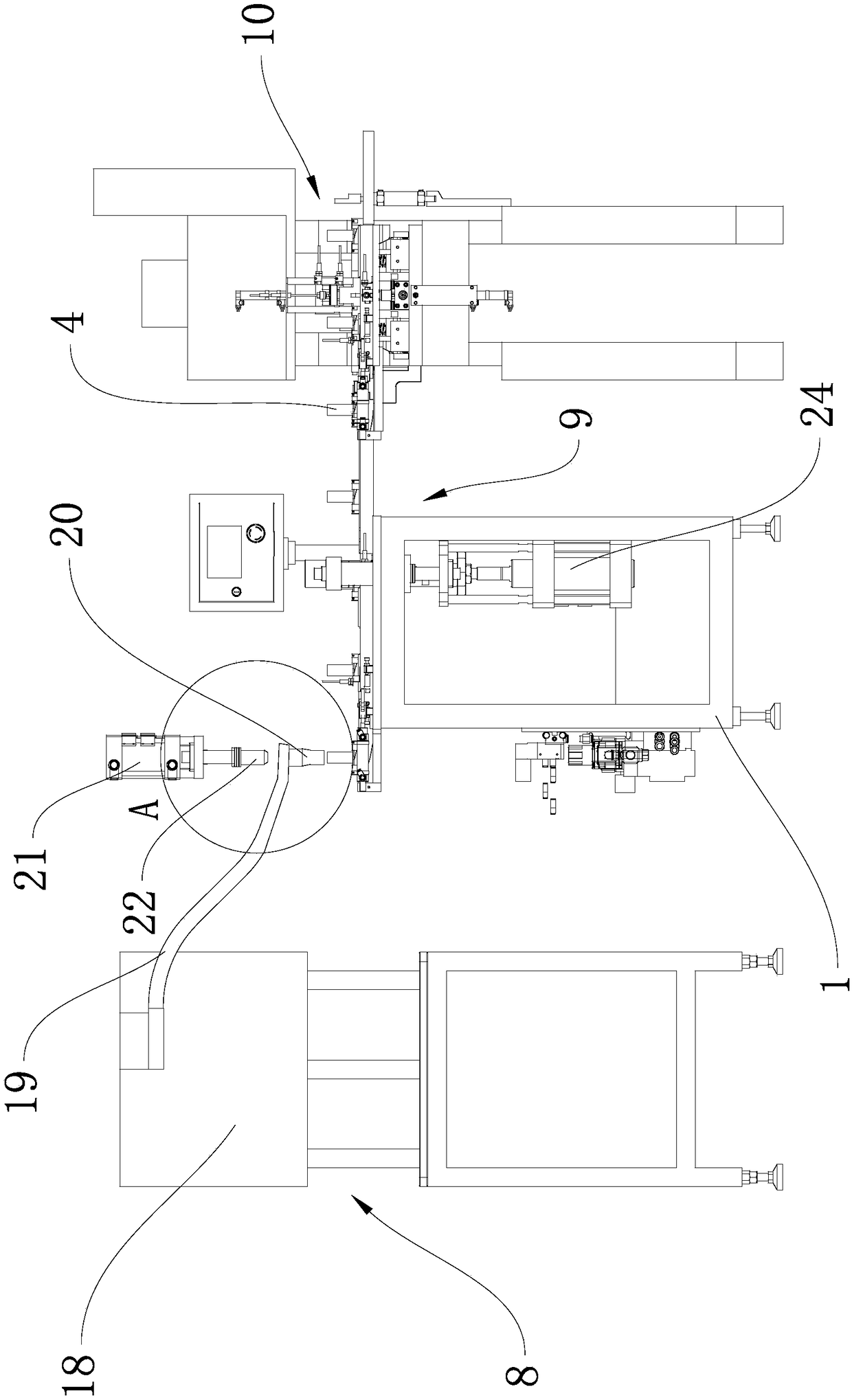

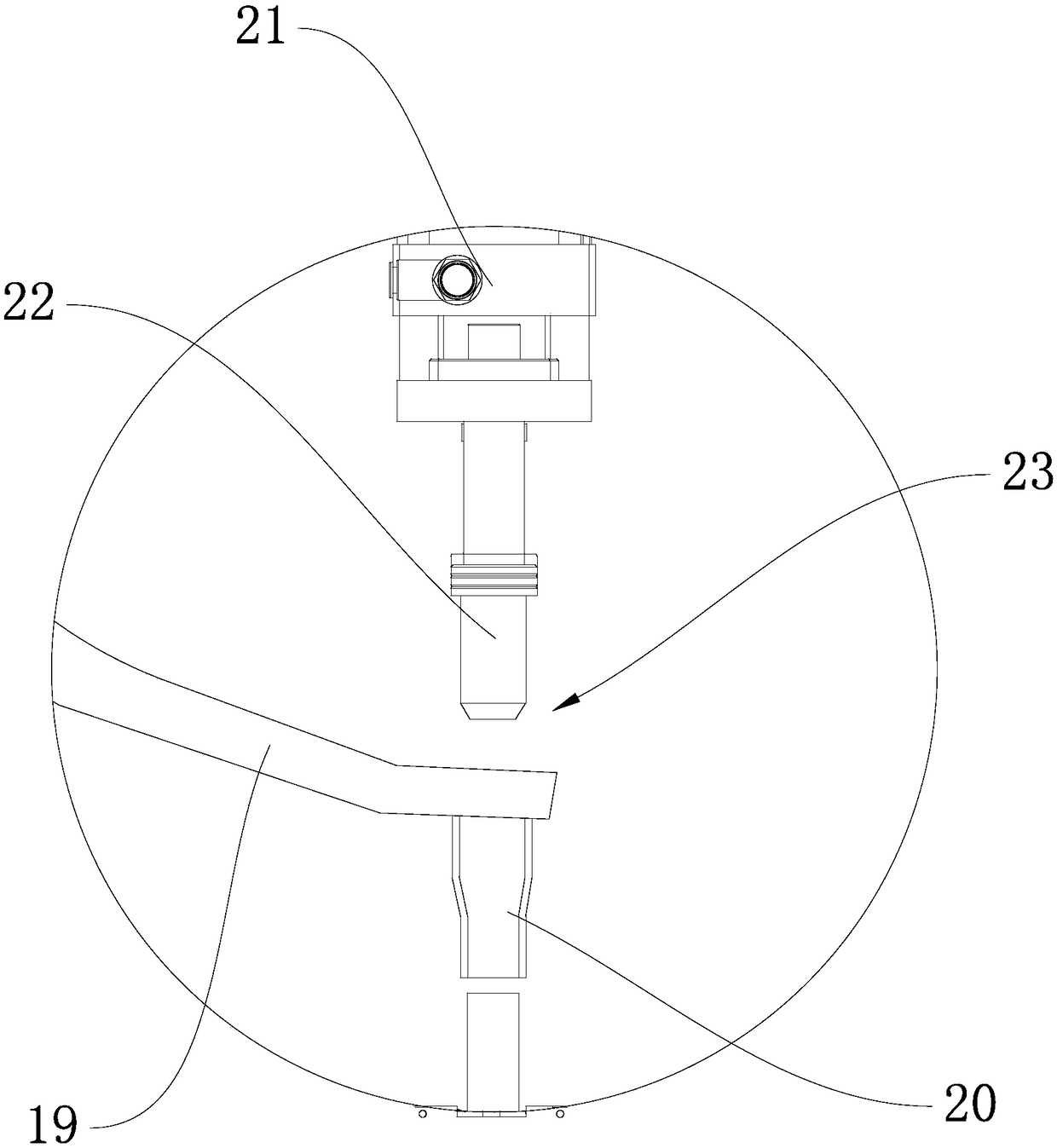

[0040] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0041] A preparation method for mosquito repellent LED lamp, comprising the following steps:

[0042] S1. Raw material preparation: purchase the existing wick posts, LED filaments, lamp bead holders, aluminum tubes, ring boxes, ceramic insulating tables, drivers, and electrode solder pieces on the market as preparation materials;

[0043] S2. Production of light-transmitting cover: hot-melt glass raw materials, and blow the glass into a light-transmitting cover;

[0044] In terms of weight fraction, the glass raw materials include 25-30% of sandstone, 30-35% of feldspar, 25-30% of dolomite, and the balance is soda ash;

[0045] S3. Material production: After cutting the aluminum tube, punch it with a lamp cap punching mac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com