Novel HP (helicobacter pylori) detector

A technology of Helicobacter pylori and detector, which is applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of absorbent splashing, low test sensitivity, missed diagnosis, etc., to avoid absorbent splashing or sucking, and measuring sensitivity High, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

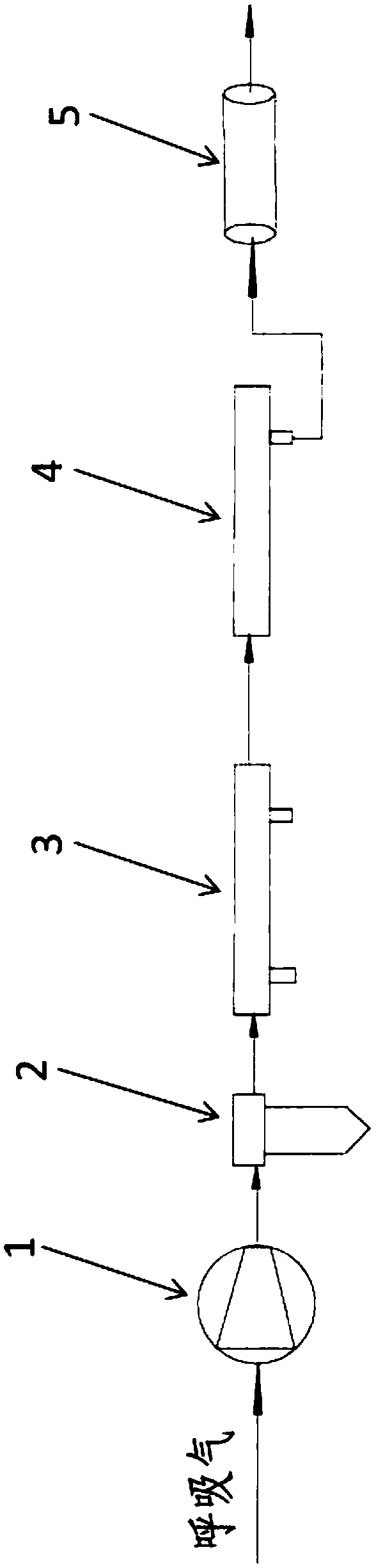

[0028] Such as figure 1 As shown, a new type of Helicobacter pylori detector, including small compressor 1, filter 2, CO 2 Thickening device and GM tube test space 5, the CO 2 Concentration device includes dehumidification membrane separator 3 and CO 2 Membrane separator 4; the GM tube test space 5 is a closed space between the two mica windows of the GM tube, the closed space is a cylinder with a volume of 100ml to 250ml, and the two end faces of the cylinder are made of Composed of two mica windows.

[0029] Utilize above-mentioned Helicobacter pylori detector to detect the method, concrete steps are as follows:

[0030] (1) Pressurize the breathing gas of the subject to 0.2-0.8 MPa through a small compressor 1, and then send it to the filter 2, which is used to filter out the liquid water mixed in the breathing gas;

[0031] (2) Send the filtered compressed breathing gas without liquid water into the CO 2 The concentration device first enters the dehumidification membr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com