Liquid crystal display panel and liquid crystal display device

A technology for liquid crystal display panels and liquid crystal display devices, applied in chemical instruments and methods, electronic equipment, applications, etc., can solve the problems of liquid crystal panel warping, liquid crystal panel warping, molecular chain shrinkage, etc., to avoid deformation, Anti-warping and anti-warping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

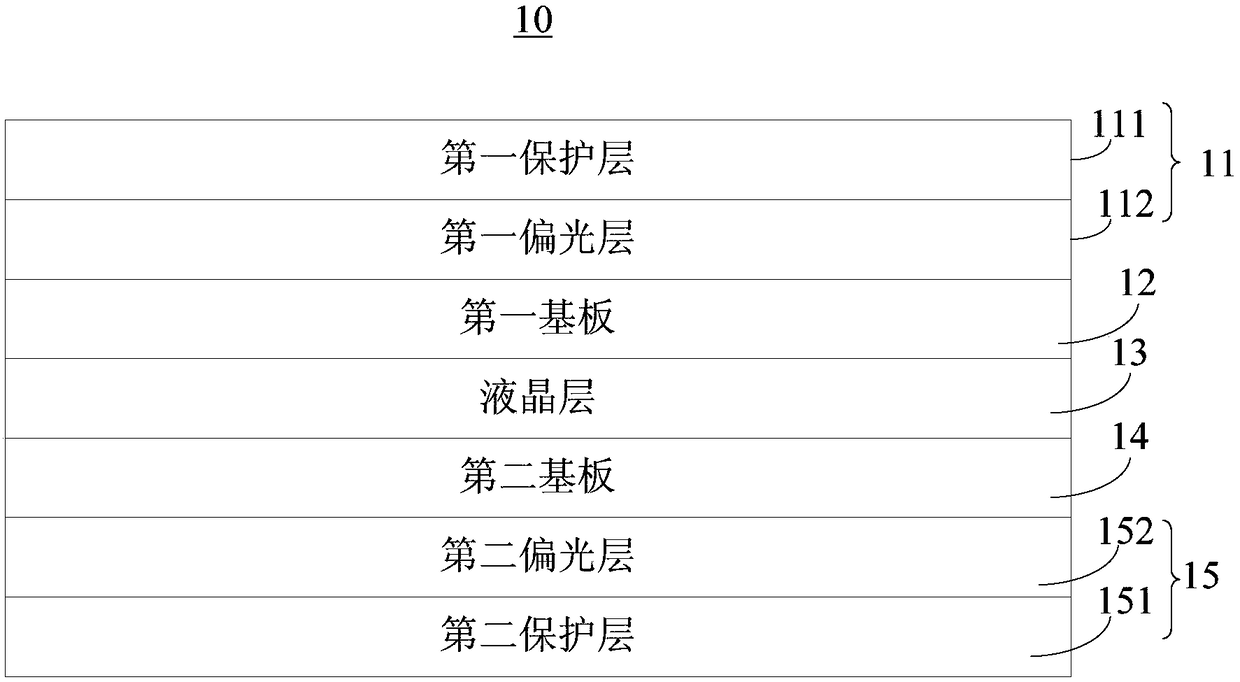

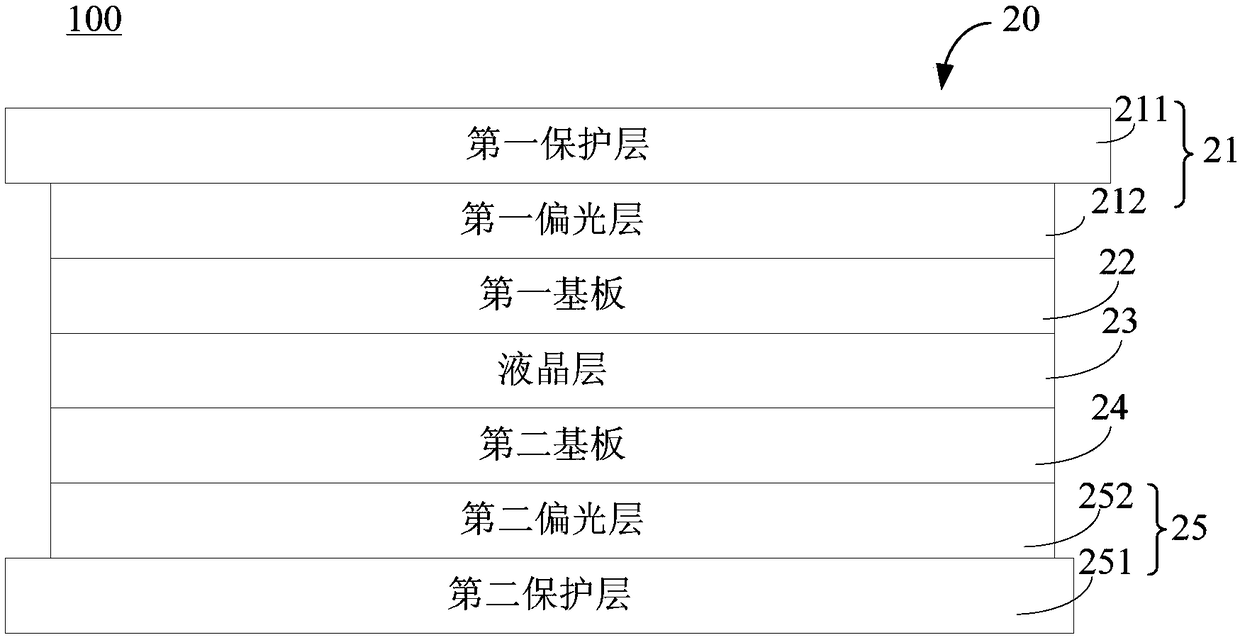

[0046] The liquid crystal display panel includes PET layer, barrier layer, PVA layer, compensation film, PSA layer, first substrate, liquid crystal layer, second substrate, PSA layer, compensation film, PVA layer, PET layer, barrier layer, quantum dot material layer, barrier layer, PET layer.

Embodiment 2

[0048] The liquid crystal display panel includes the PET layer, the PVA layer, the compensation film, the PSA layer, the first substrate, the liquid crystal layer, the second substrate, the PSA layer, and the compensation film that are arranged in sequence from top to bottom. , PVA layer, and the first quantum dot water-resistant and oxygen-resistant material layer.

Embodiment 3

[0050] The liquid crystal display panel includes a cycloolefin polymer layer, a PVA layer, a compensation film, a PSA layer, a first substrate, a liquid crystal layer, a second substrate, a PSA layer, a compensation film, a PVA layer, and a first quantum dot arranged in sequence from top to bottom. Water and oxygen resistant material layer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com