Portable composite antenna supporting tube system

A technology of antenna support and composite materials, which is applied in the direction of antenna supports/installation devices, antennas, antenna parts, etc., and can solve the problem that the height of antenna support rods cannot be met, the requirements for rapid erection cannot be met, and the weight of metal antenna support rods is heavy. and other problems, to achieve the effect of convenient unfolding and rewinding, wide range of uses and high erection height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0023] Lay the 90°, -45° and 45° glass fiber epoxy prepregs on a cylindrical mold with a diameter of 80mm in the order of layering, the thickness of the prepreg is 1mm, and the length of the prepreg is 7m; After the impregnation is finished, wrap the peelable shaping tape on the surface of the prepreg; then it is cured in the oven, and the temperature is raised from room temperature to 80°C at 2.5°C / min, and kept for 40 minutes, and then heated to 130°C at 2.5°C / min. Keep the temperature for 60min; after the temperature is stopped, cool down with the furnace to below 70℃, and release the mold into semi-finished products; cut 50mm in the axial direction of the main body of the antenna support tube; treat the outer surface of the main body of the antenna support tube and glue the canvas, and turn over the edges. edge processing.

preparation example 2

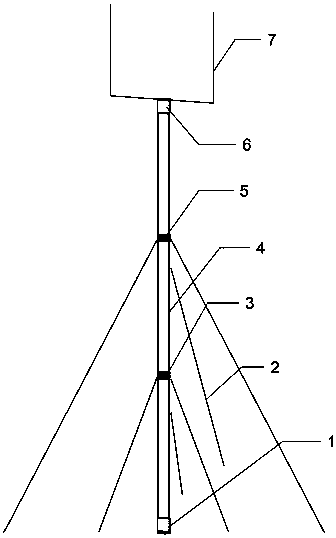

[0025] The 90°, 0° and 90° glass fiber polyethylene thermoplastic prepregs are laid on the cylindrical core mold with a diameter of 120mm in the order of layering. The thickness of the prepreg is 1.5mm, and the length of the prepreg is 8m; after the prepreg is laid, it is put into the forming mold. The schematic diagram of the mold structure is as follows figure 1 Then put it into a hot press for heating and pressure molding, apply a pressure of 0.6Mpa, keep the temperature at 160°C for 3 minutes, cool down to below 50°C, and release it into a semi-finished product; the material has been opened during the production process, and no subsequent processing is required; The outer surface of the main body of the antenna support tube is treated and the canvas is glued, and the edges are flanged.

preparation example 3

[0027]The 24K carbon fiber is dipped in the dipping tank and then wound on a cylindrical mandrel with a diameter of 120mm according to the set angle. The fiber winding thickness is 1.5mm, the winding length is 9m, and the resin viscosity is 1000cps. After the winding is completed, the excess resin on the surface is scraped off. , laying the release cloth, wrapping the surface with a peelable shaping bag; then curing in the oven, heating from room temperature to 90 °C at 4 °C / min, and holding for 40 minutes, then heating up to 140 °C at 4 °C / min, and holding for 70 minutes; stop; After warming, cool down to below 70℃ with the furnace, demould into semi-finished products; cut 80mm axially along the main body of the antenna support tube; treat the outer surface of the main body of the antenna support tube and glue the canvas, and flange the edges.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Opening size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com