A carbon nanotube modified with gold nanoparticles and its preparation method and application

A technology of gold nanoparticles and carbon nanotubes, which is applied in the direction of carbon nanotubes, single-walled carbon nanotubes, and nanocarbons, and can solve problems such as difficult control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

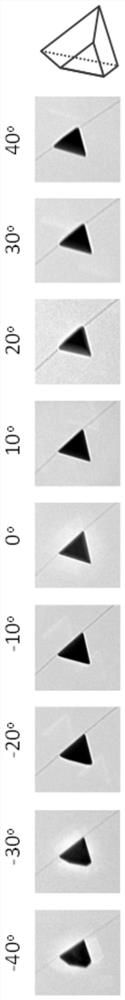

[0047] According to a preferred embodiment of the present invention, the gold nanoparticles are in the shape of a polyhedron, and the edges of the polyhedron are attached to the carbon nanotube carrier.

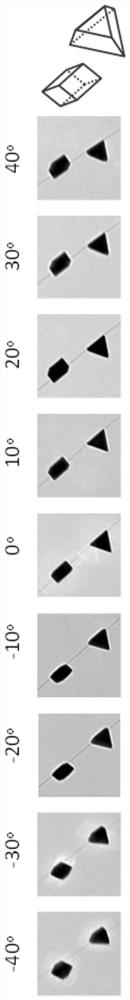

[0048] In a further preferred embodiment, as Figure 6C with Figure 6D As shown, on the carbon nanotube support, there is at least one gold nanoparticle pair for in-situ reaction, and the gold nanoparticle pair is composed of two gold nanoparticles attached to the carbon nanotube support at the edges.

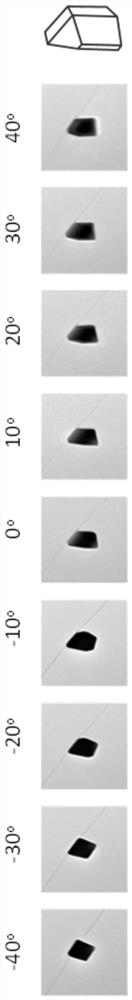

[0049] In a further preferred embodiment, such as Figure 6E As shown, the carbon nanotubes are located between a plurality of closely arranged polyhedral gold nanoparticles.

[0050] Wherein, a single gold nanoparticle can form a "hot spot" at its corners or edges, but the "hot spot" of a single gold nanoparticle is obviously weaker than the "hot spot" formed by a pair of gold nanoparticles. Therefore, in the present invention , preferably at least one pair of gold nanopa...

Embodiment 1

[0153] (1) Preparation of single-walled carbon nanotube carrier:

[0154] (1.1) prepare the ethanolic solution of cobalt acetate tetrahydrate of 0.1mmol / L, namely catalyst precursor solution;

[0155] (1.2) Put the grooved silicon wafer into the Piranha solution, heat it at about 120°C for 20 minutes, then clean it with ultrapure water, ethanol, and ultrapure water in an ultrasonic cleaner, and finally dry it with nitrogen;

[0156] (1.3) Growth of single-walled carbon nanotubes

[0157] (1.3.1) Smear the catalyst precursor solution on the silicon substrate parallel to the direction of the groove with a pipette tip, and put it into a 2.5cm diameter quartz tube with a tube furnace jacket after natural drying;

[0158] (1.3.2) Heat the tube furnace to 500°C, push the silicon chip into it, and oxidize it in the air atmosphere for 5 minutes. After the oxidation is completed, push the silicon chip out of the high-temperature zone, and inject 300 sccm of argon gas for 3 minutes to ...

Embodiment 2

[0166] The preparation process of Example 1 was repeated, with the difference being step (2.1), wherein, chloroauric acid tetrahydrate was dissolved in water to prepare a chloroauric acid solution with a concentration of 40mmol / L.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com