Application of gold nanoparticle modified carbon nanotube

A gold nanoparticle and carbon nanotube technology, applied in the field of carbon nanotubes, can solve the problems of difficult adsorption of gas molecules, complicated process, and poor detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

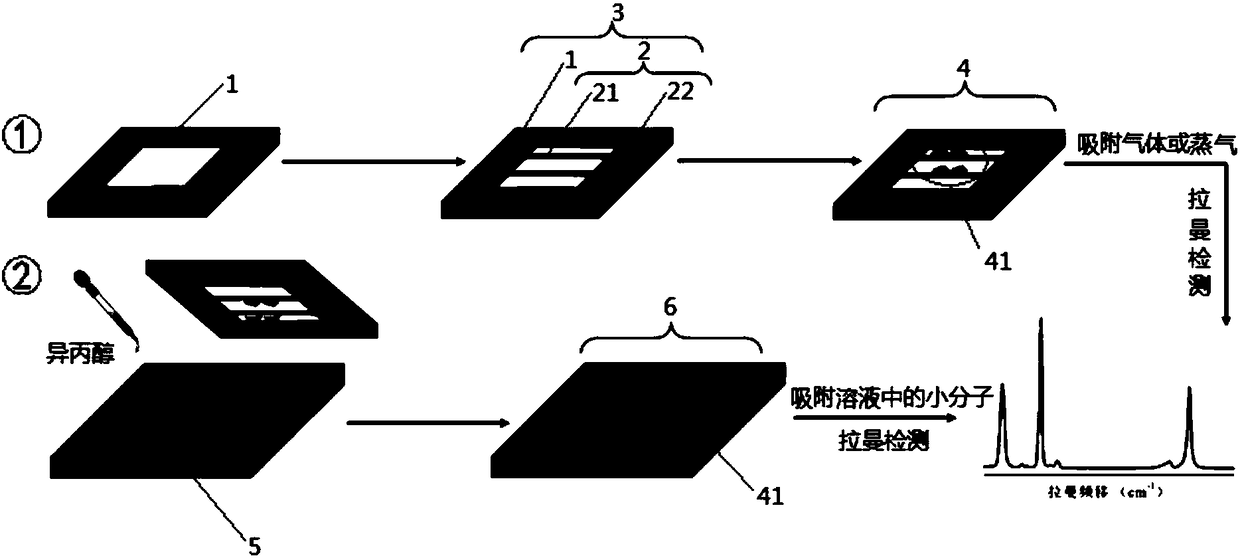

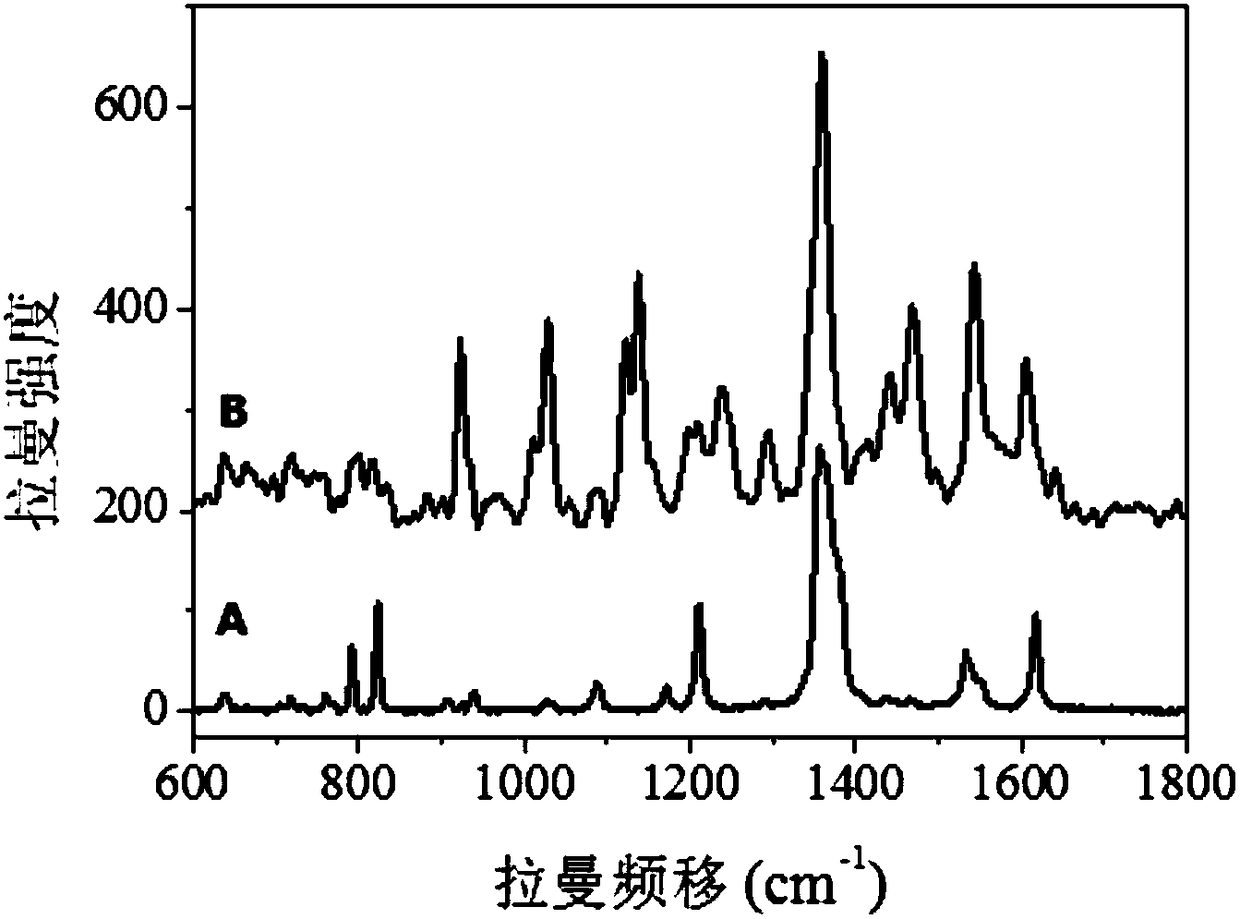

[0058] According to a preferred embodiment of the present invention, the gold nanoparticle-modified carbon nanotubes are used for surface-enhanced Raman detection of small molecular substances with conjugated structures.

[0059] Among them, on the one hand, carbon nanotubes play the role of templates in the preparation of gold nanoparticles, which shortens the distance between gold nanoparticles and improves the SERS enhancement factor; on the other hand, the large π-conjugated system of carbon nanotubes can Effectively adsorb small molecules with conjugated structures, making them close to "hot spots" to obtain effective Raman enhancement and effectively reduce the detection limit.

[0060] Another aspect of the present invention provides a method for surface-enhanced Raman detection using gold nanoparticle-modified carbon nanotubes.

[0061] Wherein, the gold nanoparticle-modified carbon nanotubes use carbon nanotubes as a carrier, and gold nanoparticles react in situ on th...

Embodiment 1

[0118] (1) Preparation of carbon nanotube carrier:

[0119] (1.1) prepare the ethanolic solution of cobalt acetate tetrahydrate of 0.1mmol / L, namely catalyst precursor solution;

[0120] (1.2) Put the hollow groove into the Piranha solution, heat it at about 120°C for 20 minutes, then clean it with ultrapure water, ethanol, and ultrapure water in an ultrasonic cleaner, and finally dry it with nitrogen;

[0121] (1.3) Growth of single-walled carbon nanotubes

[0122] (1.3.1) Smear the catalyst precursor solution on the silicon substrate parallel to the direction of the groove with a pipette tip, and put it into a 2.5cm diameter quartz tube with a tube furnace jacket after natural drying;

[0123] (1.3.2) Heat the tube furnace to 500°C, push the silicon chip into it, and oxidize it in the air atmosphere for 5 minutes. After the oxidation is completed, push the silicon chip out of the high-temperature zone, and inject 300 sccm of argon gas for 3 minutes to discharge the quartz t...

Embodiment 2

[0136] Repeat the process of embodiment 1, difference is: carry out step (3) after step (2):

[0137] (3) Transferring the suspended part of the gold nanoparticle-modified carbon nanotube support to the silicon wafer.

[0138] Among them, the silicon wafer used is a silicon wafer containing a 300nm thick silicon dioxide layer, and the silicon wafer is heated at about 120°C for 20 minutes using piranha solution (Piranha solution is a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3), and then Clean with ultrapure water, ethanol, and ultrapure water in an ultrasonic cleaner in sequence, and finally blow dry with nitrogen.

[0139] (3.1) Use a microsampler to drop 2 microliters of isopropanol (purity: MOS grade) onto the surface of the silicon wafer, and the isopropanol will spread naturally on the surface;

[0140] (3.2) Invert the gold nanoparticle-modified carbon nanotube carrier prepared in step (2), and fasten it on the silicon w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com