Method and system for detecting drug blister package defect based on machine vision

A technology of blister packaging and machine vision, which is applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve the problems of slow blister detection, low degree of automation, and light labor, etc., to improve detection reliability. , a high degree of automation, the effect of enhancing the structure characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the object, technical solution and advantages of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

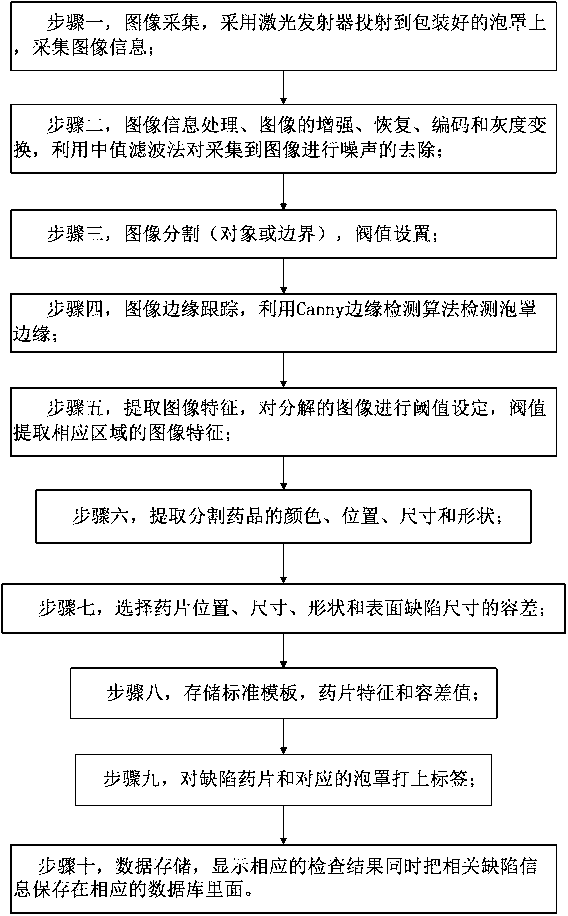

[0042] Such as figure 1 As shown, the present invention discloses a method for detecting drug blister packaging based on machine vision, which includes the following steps:

[0043] Step 1, image acquisition, using a laser transmitter to project onto the packaged blister to collect image information;

[0044] Step 2, image information processing, image enhancement, recovery, encoding and grayscale transformation, using the median filter method to remove noise from the collected image;

[0045] Step 3, image segmentation (object or boundary), threshold setting;

[0046] Step 4, image edge tracking, using the Canny edge detection algorithm to detect the edge of the blister;

[0047] Step 5, extracting image features, setting a threshold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com