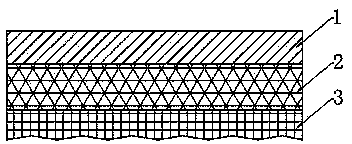

Preparing method of composite multi-layer multi-functional wall heat-preserving material

A technology of thermal insulation material and multi-layer composite, applied in the field of thermal insulation materials, to achieve the effect of excellent comprehensive effect, simple process flow and excellent fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Preparation of insulation layer: Chop the crop straw into pieces with a length of 0.5-1.5mm, and then weigh 30 parts of the chopped crop straw, 30 parts of magnesium cement, 15 parts of polystyrene foam particles, plant hair 10 parts of foaming agent, 20 parts of glass microspheres, and 10 parts of glass fiber are placed in a stirred reactor, an appropriate amount of water is added, and mixed and stirred at a speed of 50-80 rpm for 1-3 hours to obtain a mixed foaming material slurry. Then inject the above-mentioned slurry into a cuboid mold with a depth of 5 mm, smooth the surface, and press at room temperature for 2 to 3 hours to obtain a cuboid block insulation layer;

[0023] (2) Prepare the protective inner layer mixture: put the high-phosphorus soil at 800°C for 2 hours to calcine metakaolin, crush and grind the construction waste into granules with a particle size of 0.05-0.08mm, then weigh 30 parts of metakaolin, Put 20 parts of construction waste crushed mat...

Embodiment 2

[0029] The difference from Example 1 is that the raw materials of the protective outer layer include: 70 parts of cement, 40 parts of fly ash, 10 parts of ultraviolet refraction agent, and 8 parts of anti-cold agent; the raw materials of the thermal insulation layer include: 40 parts of crop straw parts, 40 parts of magnesium cement, 20 parts of polystyrene foam particles, 15 parts of plant foaming agent, 25 parts of glass microspheres, and 15 parts of glass fiber; the raw materials of the protective inner layer include: 50 parts of metakaolin, crushed construction waste 40 parts of material, 30 parts of binder, wherein, the particle size of the crushed construction waste material is 0.08mm.

[0030] The thickness of the mold in the preparation step (1) is 15 mm, and the thickness of the mold in the preparation step (4) is 22 mm.

[0031] The multilayer composite multifunctional wall insulation material prepared by the above method has a protective outer layer with a thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com