Method for detecting concentration of impurities in ultra-high-purity germanium rod or ingot

A technology of impurity concentration and detection method, which is applied to measurement devices, instruments, material analysis by electromagnetic means, etc., can solve the problems of inability to detect the impurity concentration of ultra-high-purity germanium products, low efficiency, and no objective basis for selecting slice points. Achieve the effect of stable measurement voltage, accurate measurement and simple operation

Inactive Publication Date: 2018-07-31

FIRST SEMICON MATERIALS

View PDF2 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the single low-temperature Hall detection method is only suitable for testing thin flake samples. For crystal rods, the section must be sliced and cleaned before measurement, which is too inefficient, and there is no objective basis for selecting the slice point, which has a certain blindness

Therefore, low-temperature Hall detection is feasible as a confirmatory final test, but it cannot detect the overall impurity concentration of rod-shaped or ingot-shaped ultra-high-purity germanium products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0023] Embodiment 1 provided by the present invention uses a model KDB-1A impurity concentration detector to provide a constant current source, and can automatically record and transmit equidistant voltage drops measured by probes to a dedicated microprocessor.

[0024] The method of the present invention will be described in detail below in conjunction with Embodiment 1.

[0025] Example 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| Mobility | aaaaa | aaaaa |

| Radial length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Login to view more

Abstract

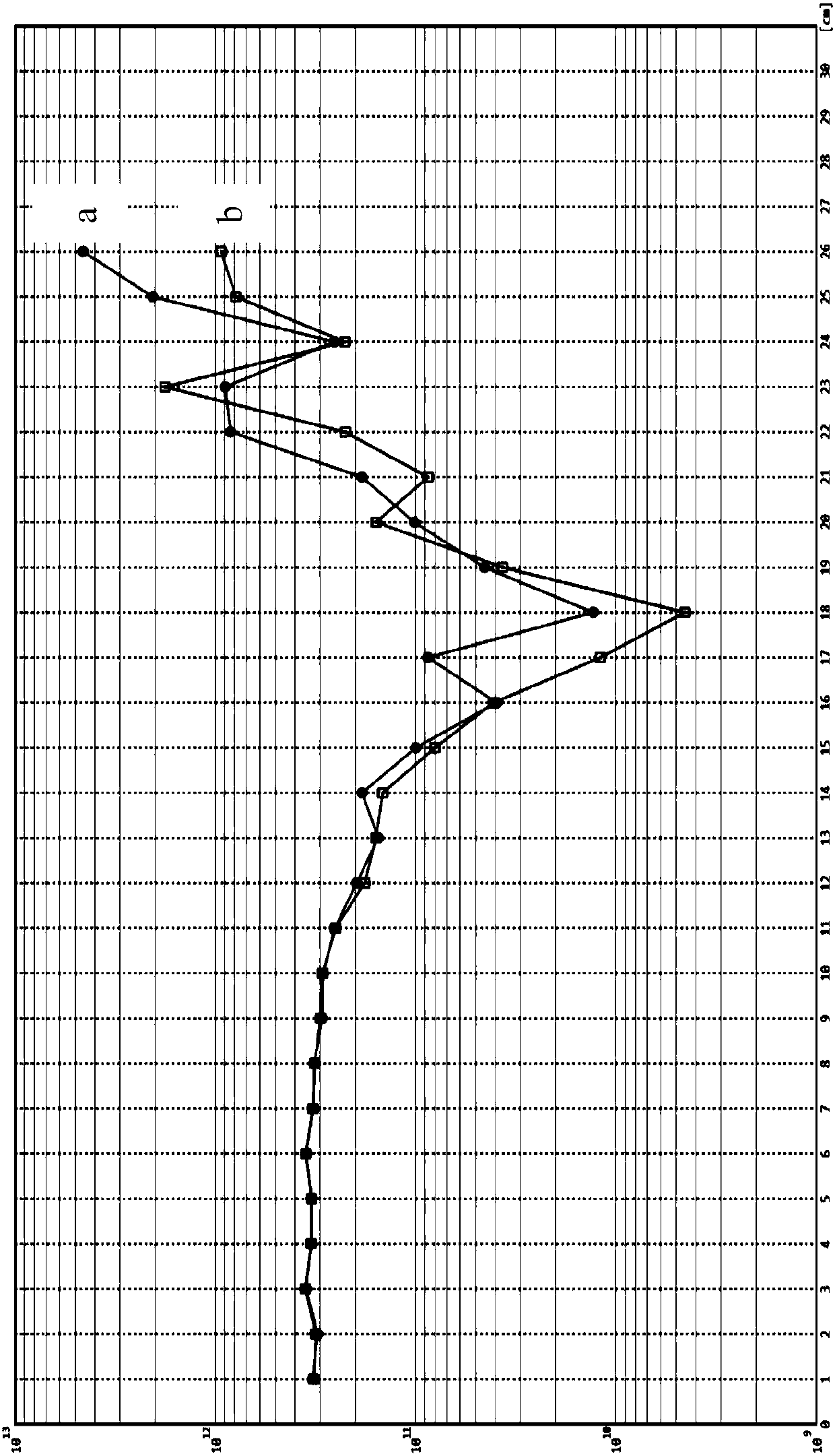

The invention provides a method for detecting the concentration of impurities in an ultra-high-purity germanium rod or ingot. According to the invention, a direct-current two-probe method is used fordetecting impurity concentration; the germanium rod or ingot is detected at a constant temperature of 77 K; any measurement point in the radial length of the germanium rod or ingot is coated with indium-gallium alloy; two probes measure equal-distance voltage drop U, and resistivity rho is calculated according to the function relation that rho is equal to (U+S) / (I*L); and then the average net impurity concentration n of the germanium rod or ingot between the probes is calculated according to the equation that n is equal to rho*q*mu. The method provided by the invention overcomes the problem that the integral impurity concentration of a germanium rod or ingot cannot be detected in the prior art, guarantees the integrity of a to-be-detected sample, and is accurate in detection results, highin detection efficiency and beneficial for industrialization.

Description

technical field [0001] The invention relates to the field of detection of semiconductor germanium rods or ingots, in particular to a method for detecting the impurity concentration of ultra-high-purity germanium rods or ingots. Background technique [0002] The germanium products currently on the market are generally purified by zone melting after chemical purification, and finally reach a purity of 5-6N after pulling a single crystal. Because the impurity content of germanium samples with a purity lower than 6N is different from that at room temperature (23±5°C) Resistivity has a certain corresponding relationship, so the current detection requirements for this purity germanium product are mainly electrical properties, that is, the size of resistivity. [0003] For zone-melted germanium ingots, the volume resistance is usually measured by two-probe resistivity detection method at room temperature (23±5°C). At present, there are relevant standards for two-probe resistivity d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more IPC IPC(8): G01N27/04G01N27/26

CPCG01N27/041G01N27/26

Inventor 邓杰赵青松朱刘

Owner FIRST SEMICON MATERIALS

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap