DBR structure and LED chip provided with DBR structure

A technology of LED chip and layered structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of the influence of incident light reflectivity and the reduction of large-angle incident light reflectivity, etc., to reduce production costs, improve reflectivity, The effect of simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further elaborated below by describing a preferred specific embodiment in detail in conjunction with the accompanying drawings.

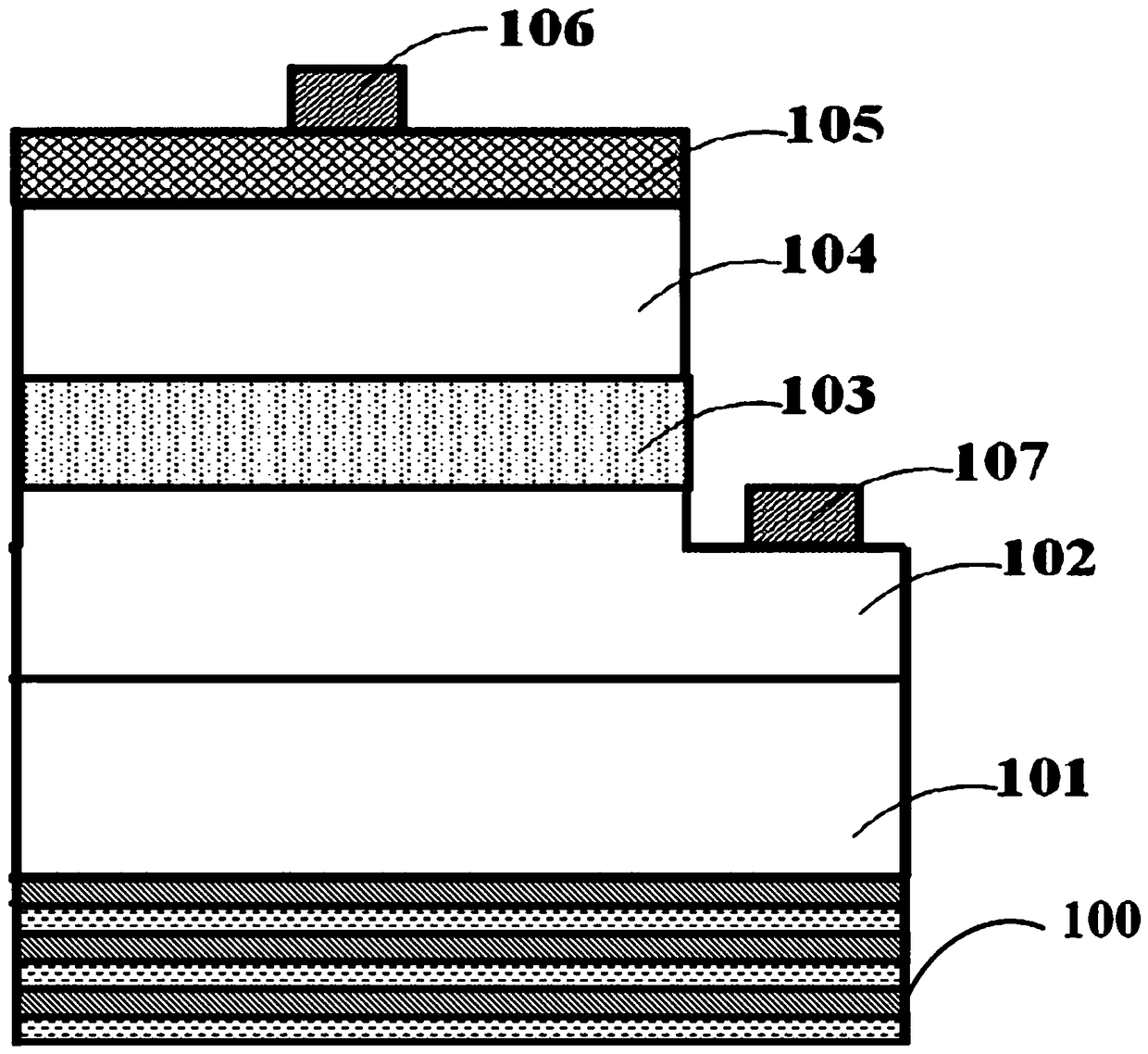

[0018] Such as figure 1 As shown, an LED chip with a DBR structure in the present invention includes: an epitaxial layer is formed by epitaxial growth on a sapphire substrate 101 of a wafer; Layer 102, light emitting layer 103 and P-type layer 104.

[0019] By means of photolithography or plasma gas etching, the P-type layer 104, light-emitting layer 103, and part of the N-type layer 102 are etched and removed at a distance from the edge of the epitaxial layer until the N-type layer is exposed. Layer 102, forming a step; the step serves as an N-type region of each LED chip. An N electrode 107 is fabricated on the steps of the exposed N-type layer 102, and a conductive layer 105 is formed on the surface of the P-type layer 104 by means of evaporation or metal sputtering. The P electrode 106 is formed on the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com