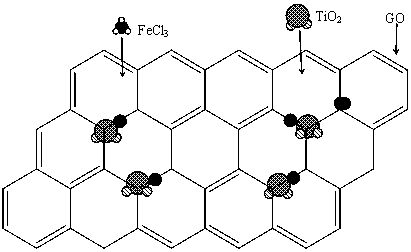

Preparation method of iron-modified TiO2/GO ternary composite material for degradaging VOCs (volatile organic compounds)

A composite material, SO4 technology, applied in separation methods, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as low photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] specific implementation plan

[0009] 10 mg of GO was weighed, dissolved in 30 ml of deionized water, and the solution was sonicated for 1 h to obtain a GO dispersion. Weigh 100 mg of Ti(SO 4 ) 2 , mixed with the GO dispersion, placed on a magnetic stirrer, stirred for 1 h, so that the Ti(SO 4 ) 2 Mix well with GO and weigh 10 mg FeCl 3 Add it into the mixed solution, stir for 2.5 h, mix evenly, slowly pour the obtained mixed solution into a polytetrafluoroethylene-lined reactor, under the pressure of 2 MPa, the reaction temperature is 210 ℃, and the hydrothermal reaction is carried out under the assistance of microwave 8 h, after the reaction was completed and naturally cooled down to room temperature, the suspension in the reactor was taken out, washed and centrifuged with 60 ml of deionized water, placed in a vacuum drying oven, and dried at 80°C for 24 h to obtain Fe- TiO 2 / GO Composite. The composite material is used as the photocatalytic filler of the phot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com