Radiation cooling glass and preparation method thereof

A glass and glass substrate technology, applied in glass manufacturing equipment, glass forming, glass reshaping, etc., can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

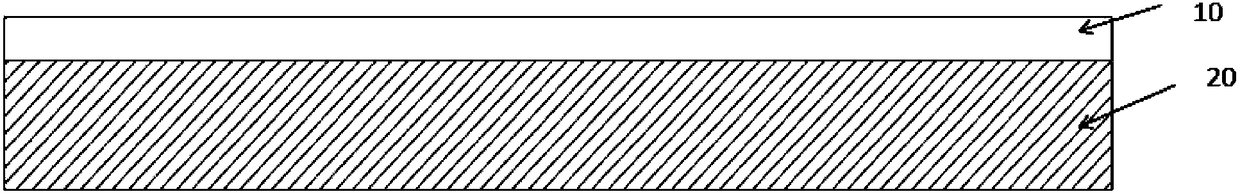

[0024] This embodiment provides a radiation cooling glass, comprising: a glass substrate 20 and a transparent radiation cooling film coating 10, the glass substrate 20 is located under the radiation cooling film coating, and the glass substrate 20 is ordinary glass. Wherein, the thickness of the transparent radiation cooling film coating 10 is 1-30um, and the components and mass parts of the transparent radiation cooling film coating 10 are: polymer resin: 20-40 parts, micron powder: 25-40 parts 50 parts, paint additives: 3-10 parts, thinner: 20-30 parts. Wherein, it should be noted that the thickness of the transparent radiation cooling film coating 10 is determined according to the comprehensive requirements of cooling, lighting and aesthetics.

[0025] The polymer resin in the component 10 of the transparent radiation cooling film coating is water-based polyurethane and / or epoxy resin. The micron powder in the components contains at least indium tin oxide (ITO), titanium d...

Embodiment 2

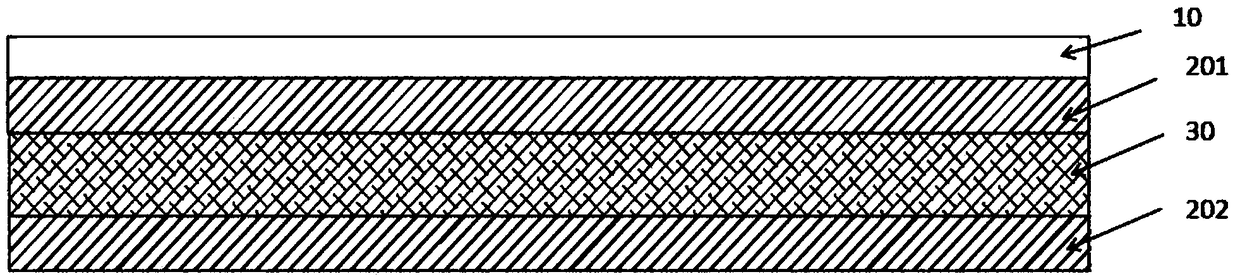

[0031] This embodiment provides a combination of the first glass substrate 201 and the second glass base layer 202 to form a double-layer structure to replace the single-layer glass substrate 20 in the first embodiment. That is, the glass substrate 20 is set as a double-layer structure, the glass substrate 20 is divided into upper and lower layers, the first glass substrate 201 is located below the transparent radiation cooling film coating 10, the second glass substrate 202 is located below the first glass substrate 201, and the second glass substrate 202 is located below the first glass substrate 201. A cavity 30 is formed between the first glass substrate 201 and the second glass substrate 202 . Air and / or Ar are contained in the cavity 30, so that the heat insulation effect can be increased, so that the high-temperature heat outside cannot easily enter the room through the glass substrate 20, while the heat inside the room can radiate into space through the transparent radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com