Environment-friendly functional anhydrous stemming and preparation method thereof

An anhydrous taphole clay and a functional technology, which is applied in the field of functional environmental protection anhydrous taphole clay and its preparation, and can solve the problems of small effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The embodiment of the present invention provides a functional environment-friendly anhydrous tap clay, wherein the mass percentage of SiC in the silicon carbide is ≥80%, and the content of Al in the modified alumina powder is greater than or equal to 80%. 2 O 3 The mass percentage content is greater than or equal to 88%, the carbide mass percentage content in the carbide dust removal powder is greater than or equal to 92%, and the moisture content of the modified resin is less than 0.5%.

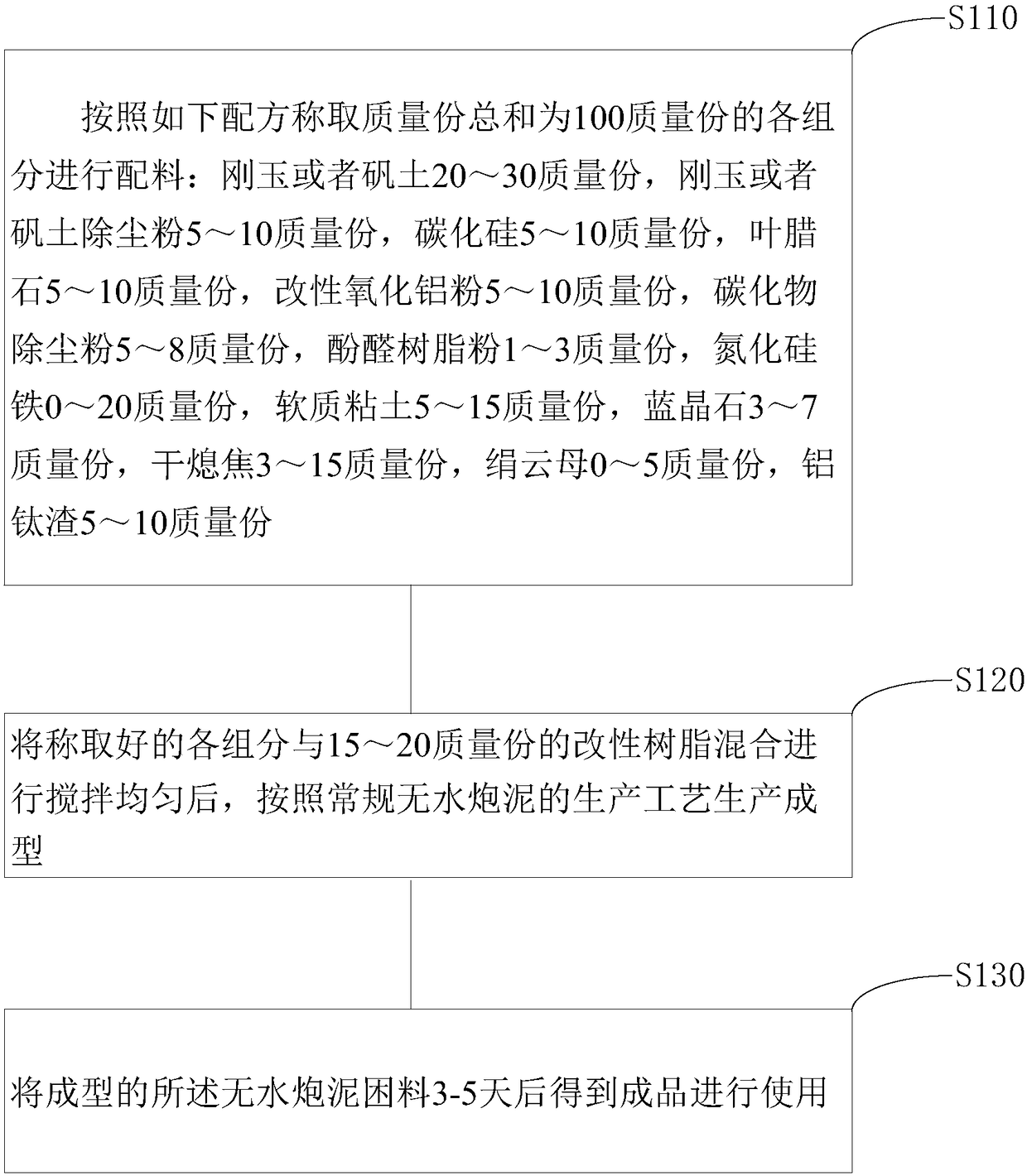

[0029] The distribution ratio of each group is as follows:

[0030] 20-30 parts by mass of corundum or bauxite, 5-10 parts by mass of corundum or bauxite dusting powder, 5-10 parts by mass of silicon carbide, 5-10 parts by mass of pyrophyllite, 5-10 parts by mass of modified alumina powder, carbide 5-8 parts by mass of dust removal powder, 1-3 parts by mass of phenolic resin powder, 0-20 parts by mass of ferrosilicon nitride, 5-15 parts by mass of soft clay, 3-7 parts by mass of kyan...

Embodiment 2

[0034] The embodiment of the present invention provides a functional environment-friendly anhydrous tap clay, wherein the mass percentage of SiC in the silicon carbide is ≥80%, and the content of Al in the modified alumina powder is greater than or equal to 80%. 2 O 3 The mass percentage content is greater than or equal to 88%, the carbide mass percentage content in the carbide dust removal powder is greater than or equal to 92%, and the moisture content of the modified resin is less than 0.5%.

[0035] The distribution ratio of each group is as follows:

[0036] 26 parts by mass of corundum or bauxite, 7 parts by mass of corundum or bauxite dust-removing powder, 5 parts by mass of silicon carbide, 7 parts by mass of pyrophyllite, 5 parts by mass of modified alumina powder, 5 parts by mass of carbide dust-removing powder, 2 parts by mass of phenolic resin parts by mass, 8 parts by mass of 200-mesh ferrosilicon nitride, 10 parts by mass of soft clay, 5 parts by mass of kyanite...

Embodiment 3

[0039] The embodiment of the present invention provides a functional environment-friendly anhydrous tap clay, wherein the mass percentage of SiC in the silicon carbide is ≥80%, and the content of Al in the modified alumina powder is greater than or equal to 80%. 2 O 3The mass percentage content is greater than or equal to 88%, the carbide mass percentage content in the carbide dust removal powder is greater than or equal to 92%, and the moisture content of the modified resin is less than 0.5%.

[0040] The distribution ratio of each group is as follows:

[0041] 25 parts by mass of corundum or bauxite, 5 parts by mass of corundum or bauxite dust-removing powder, 8 parts by mass of silicon carbide, 6 parts by mass of pyrophyllite, 6 parts by mass of modified alumina powder, 8 parts by mass of carbide dust-removing powder, 2 parts by mass of phenolic resin parts by mass, 15 parts by mass of 200-mesh ferrosilicon nitride, 5 parts by mass of soft clay, 3 parts by mass of kyanite,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com