Copolymerization method of ethylene and alkenyl-terminated silane/siloxane

A technology of terminal alkenyl silane and siloxane, applied in the field of copolymerization of ethylene and terminal alkenyl silane/siloxane, can solve the problems of high price, low polymerization activity, low polymer molecular weight and branching degree, etc. The effect of increasing content, high polymerization activity and broad industrial application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

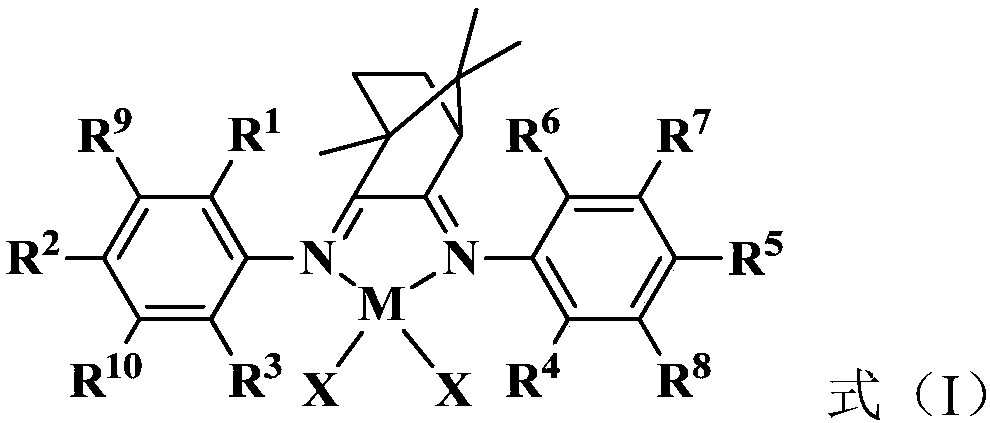

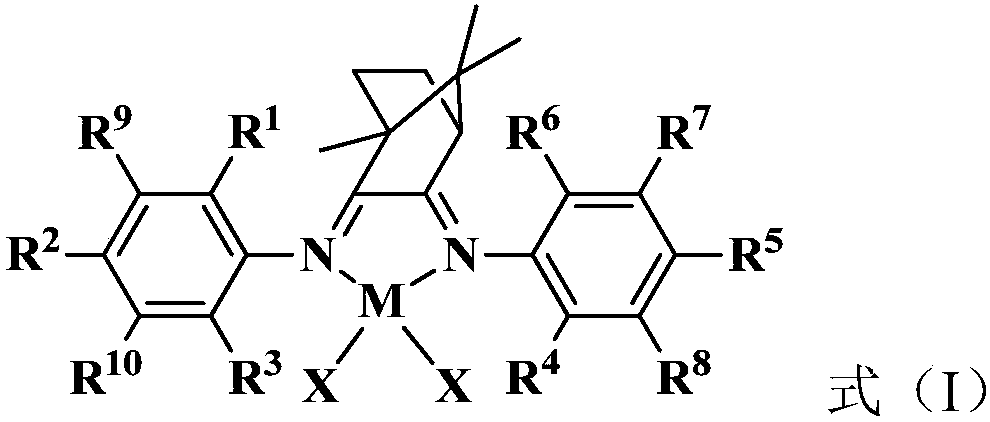

[0026] According to a preferred embodiment of the present invention, the main catalyst is selected from at least one of the following complexes,

[0027] Complex 1: R 1 =R 3 =R 4 =R 6 = Me,R 2 =R 5 = H, X = Br;

[0028] Complex 2: R 1 =R 3 =R 4 =R 6 =Et,R 2 =R 5 = H, X = Br;

[0029] Complex 3: R 1 =R 3 =R 4 =R 6 =iPr, R 2 =R 5 = H, X = Br;

[0030] Complex 4: R 1 =R 2 =R 3 =R 4 =R 5 =R 6 =Me, X=Br;

[0031] Complex 5: R 1 =R 3 =R 4 =R 6 = Me,R 2 =R 5 =Br, X=Br;

[0032] Complex 6: R 1 =R 3 =R 4 =R 6 = Me,R 2 =R 5 = Et, X = Br;

[0033] Complex 7: R 1 =R 3 =R 4 =R 6 =Et,R 2 =R 5 =Me, X=Br;

[0034] Complex 8: R 1 =R 3 =R 4 =R 6 =Et,R 2 =R 5 =Br, X=Br;

[0035] Complex 9: R 1 =R 3 =R 4 =R 6 = F, R 2 =R 5 = H, X = Br;

[0036] Complex 10: R 1 =R 3 =R 4 =R 6 = Cl, R 2 =R 5 = H, X = Br;

[0037] Complex 11: R 1 =R 3 =R 4 =R 6 =Br,R 2 =R 5 = H, X = Br;

[0038] Complex 12: R 1 =R 3 =R 4 =R 6 = Me,R 2 =R 5...

Embodiment 1

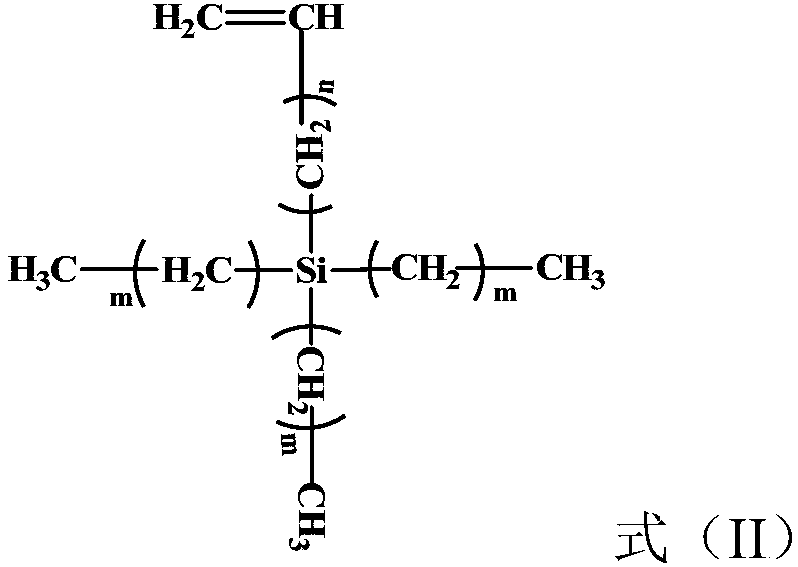

[0085] The 1L stainless steel polymerization kettle equipped with mechanical stirring was continuously dried at 130°C for 6hrs, vacuumized while hot and heated with N 2 Gas replacement 3 times; add 6.5 mg (10 μmol) of complex 2, then evacuate and replace 3 times with ethylene, inject 500 mL of toluene, add 6.5 mL of methylaluminoxane (MAO) (1.53 mol / L toluene solution) , make Al / Ni=1000, 5mL of allyltrimethoxysilane (28.7mmol), at 60°C, keep ethylene pressure of 10atm, and stir for 30min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and performance parameters of the polymer are shown in Table 1.

Embodiment 2

[0087] The 1L stainless steel polymerization kettle equipped with mechanical stirring was continuously dried at 130°C for 6hrs, vacuumized while hot and heated with N 2 Gas replacement 3 times; add 6.5 mg (10 μmol) of complex 2, then vacuumize and replace with ethylene for 3 times, inject 500 mL of toluene, and then add 6.5 mL of methylaluminoxane (MAO) (1.53 mol / L toluene solution) , make Al / Ni=1000, 8mL of allyltrimethoxysilane (45.9mmol), at 60°C, keep 10atm of ethylene pressure, and stir for 30min. Finally, it was neutralized with an ethanol solution acidified with 5 volume % hydrochloric acid to obtain a polymer. The polymerization activity and performance parameters of the polymer are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com