A method to improve the enhanced Raman scattering performance of nanoporous metal surface

A technology that enhances Raman scattering and nanoporosity, and is applied in Raman scattering, metal material coating technology, sputtering plating, etc., to achieve the effect of wide application, wide application range and controllable radiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

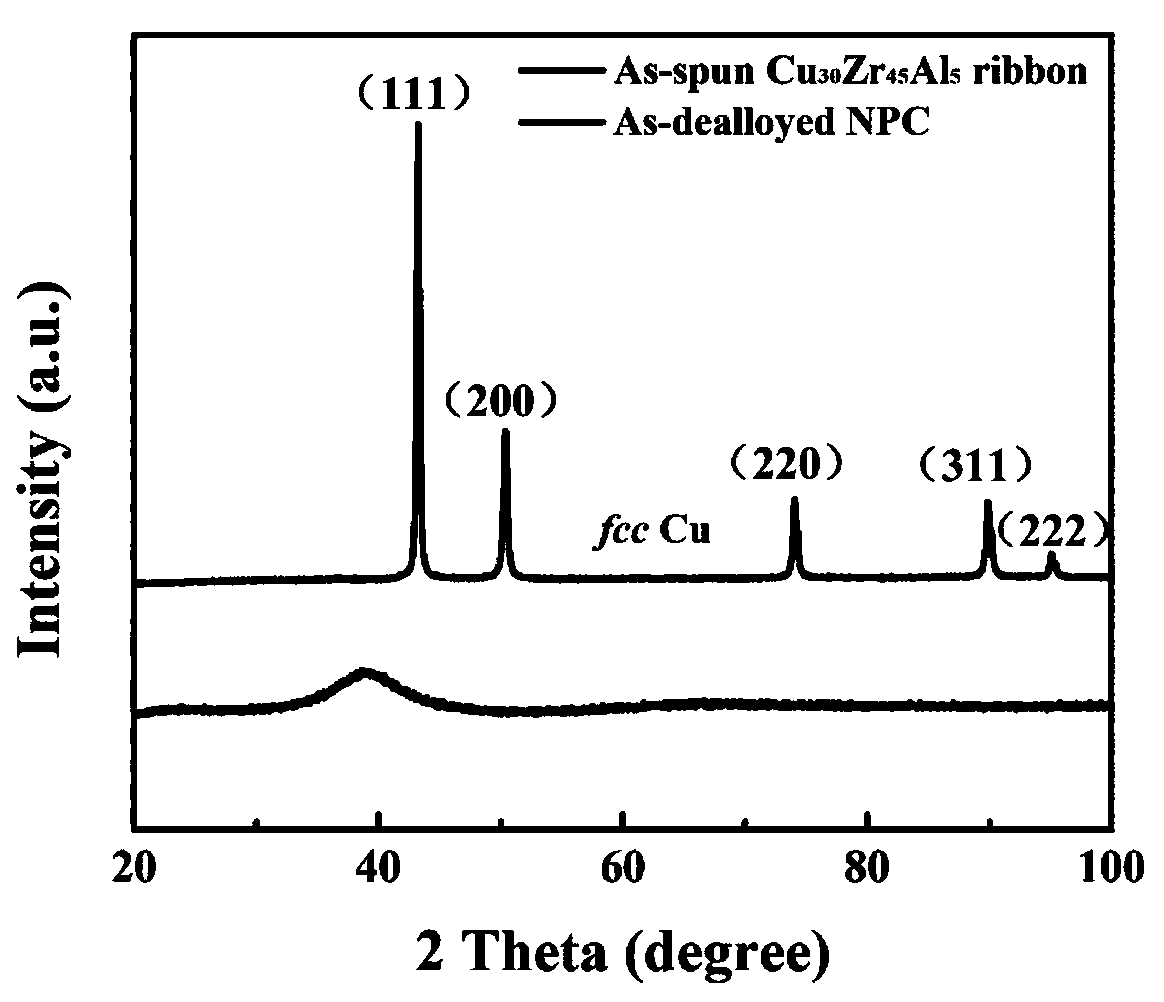

[0026] (1) with Cu 30 Zr 65 Al 5 Three-dimensional bicontinuous nanoporous copper, Cu 30 Zr 65 Al 5 X-ray diffraction experiments confirmed the characteristics of the amorphous structure of thin strip samples (such as figure 1 shown);

[0027] (2) Load the prepared nanoporous copper into the tandem static accelerator, and vacuum it to 1×10 -3 ~2×10 - 4 Pa;

[0028] (3) The energy is 9MeV, the dose is 9.36×10 13 ions / cm 2 Irradiation of gold ions, the irradiation temperature is room temperature, and the irradiation time is 1 hour;

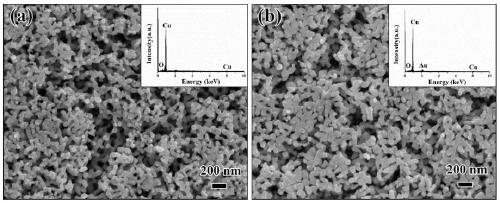

[0029] (4) After irradiation, the surface of nanoporous copper becomes rough, the ligaments are coarsened, and the pores become smaller, thus providing more active sites, and the alloying effect is produced due to the implantation of gold ions after irradiation (such as figure 2 shown);

[0030] (5) With R6G as the probe molecule, prepare 10 -4 The probe molecular solution with mol / L concentration was used as the substrate before and ...

Embodiment 2

[0032] (1) with Cu 30 Zr 65 Al 5 Three-dimensional bicontinuous nanoporous copper, Cu 30 Zr 65 Al 5 X-ray diffraction experiments confirmed the characteristics of the amorphous structure of thin strip samples (such as figure 1 shown);

[0033] (2) Load the prepared nanoporous copper into the tandem static accelerator, and vacuum it to 1×10 -3 ~2×10 - 4 Pa;

[0034] (3) The energy is 3MeV, the dose is 3.36×10 14 ions / cm 2 Copper ion irradiation, the irradiation temperature is room temperature, and the irradiation time is 1 hour;

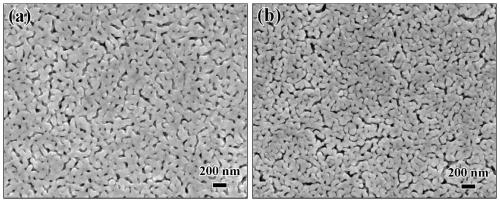

[0035](4) After irradiation, the surface of nanoporous copper becomes rough, the ligaments are coarsened, and the pores become smaller, thus providing more active sites;

[0036] (5) With R6G as the probe molecule, prepare 10 -4 The probe molecular solution with mol / L concentration was used as the substrate with nanoporous copper before and after copper ion irradiation, and its performance was tested, and the SERS performance was improved...

Embodiment 3

[0039] (1) with Cu 50 Zr 45 Al 55 Amorphous alloy thin strips are used as precursors, and three-dimensional bicontinuous nanoporous metals are prepared by chemical dealloying;

[0040] (2) Load the prepared nanoporous copper into the tandem static accelerator, and vacuum it to 1×10 -3 ~2×10 - 4 Pa;

[0041] (3) The energy is 9MeV, the dose is 9.36×10 13 ions / cm 2 Irradiation of gold ions, the irradiation temperature is room temperature, and the irradiation time is 1 hour;

[0042] (4) After the irradiation, the surface of nanoporous copper becomes rough, the ligaments are coarsened, and the pores become smaller, thus providing more active sites, and the alloying effect is produced due to the implantation of gold ions after irradiation;

[0043] (5) With R6G as the probe molecule, prepare 10 -4 mol / L concentration of the probe molecule solution, using nanoporous copper before and after gold ion irradiation as the substrate, to detect its performance, the SERS performan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com