A kind of braidable multi-walled carbon nanotube modified composite phase change material and preparation method thereof

A technology of multi-walled carbon nanotubes and composite phase change materials, applied in heat exchange materials, chemical instruments and methods, wet spinning, etc., can solve the problems of low heat storage density, low thermal conductivity and large volume change, etc. Achieve high thermal conductivity, high tensile strength, and improve heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

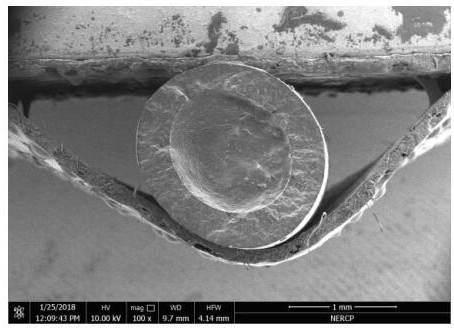

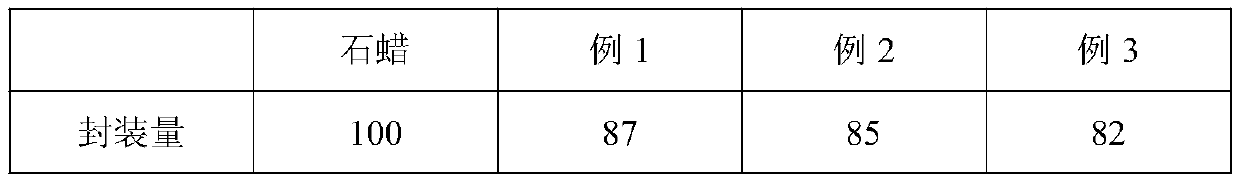

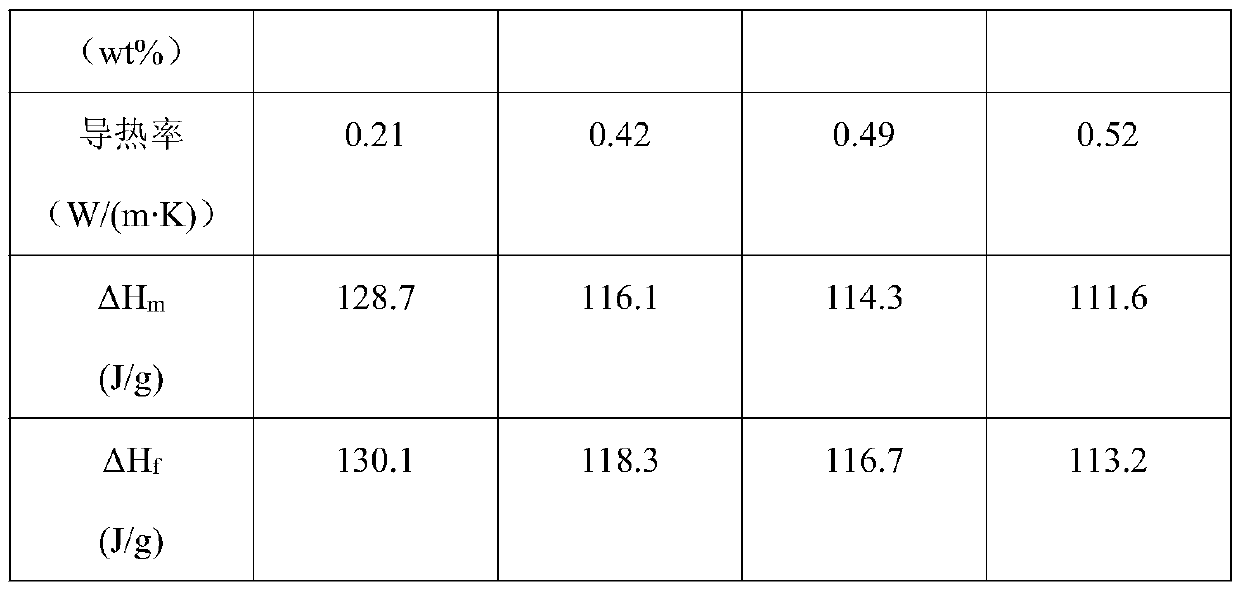

[0032] Embodiment 1: A kind of woven multi-wall carbon nanotube modified composite phase change material, comprising multi-wall carbon nanotube modified polypropylene hollow fiber membrane, the inner wall of the multi-wall carbon nanotube modified polypropylene hollow fiber membrane Adsorbed full of paraffin, the membrane cavity is filled with a mixture of paraffin and heat-conducting materials;

[0033] The membrane outer diameter of the multi-walled carbon nanotube modified polypropylene hollow fiber membrane is 1mm, and the porosity is 50%;

[0034] The polypropylene is a homopolypropylene; or a branched high melt strength homopolypropylene with a melt index of 0.5g / 10min;

[0035] The length of the multi-walled carbon nanotubes is 3 μm;

[0036] The heat-conducting material is copper powder whose particle size is below the micron scale;

[0037] The paraffin is solid at room temperature and has 17 carbon atoms;

[0038] The mass ratio of the heat conduction material in th...

Embodiment 2

[0039] Embodiment 2: A kind of braidable multi-wall carbon nanotube modified composite phase change material, including multi-wall carbon nanotube modified polypropylene hollow fiber membrane, the inner wall of the multi-wall carbon nanotube modified polypropylene hollow fiber membrane Adsorbed full of paraffin, the membrane cavity is filled with a mixture of paraffin and heat-conducting materials;

[0040] The membrane outer diameter of the multi-wall carbon nanotube modified polypropylene hollow fiber membrane is 2mm, and the porosity is 65%;

[0041] Described polypropylene is homopolypropylene; Or contains branched high melt strength homopolypropylene, and its melt index is 2g / 10min;

[0042] The length of the multi-walled carbon nanotubes is 11 μm;

[0043] The heat-conducting material is a carbon nanotube with a particle size below the micron scale;

[0044] The paraffin is solid at room temperature and has 26 carbon atoms;

[0045] The mass ratio of the heat-conducti...

Embodiment 3

[0046] Embodiment 3: A kind of braidable multi-wall carbon nanotube modified composite phase change material, comprising multi-wall carbon nanotube modified polypropylene hollow fiber membrane, described multi-wall carbon nanotube modified polypropylene hollow fiber membrane wall Adsorbed full of paraffin, the membrane cavity is filled with a mixture of paraffin and heat-conducting materials;

[0047] The membrane outer diameter of the multi-walled carbon nanotube modified polypropylene hollow fiber membrane is 3mm, and the porosity is 80%;

[0048] Described polypropylene is homopolypropylene; Or contains branched high melt strength homopolypropylene, and its melt index is 4g / 10min;

[0049] The length of the multi-walled carbon nanotubes is 20 μm;

[0050] The heat-conducting material is a mixture of carbon nanotubes, graphene, expanded graphite and copper powder with a particle size below the micron level in a mass ratio of 1:1:1:1;

[0051] Described paraffin is solid at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com