Double-sided light emitting diode (LED) light source structure based on COB packaging structure

A LED light source and double-sided light-emitting technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of affecting the light efficiency and stability of LED light sources, affecting the service life of LED light sources, and reducing light efficiency, so as to prevent high Voltage electrostatic breakdown, improve safety and stability, and improve light efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

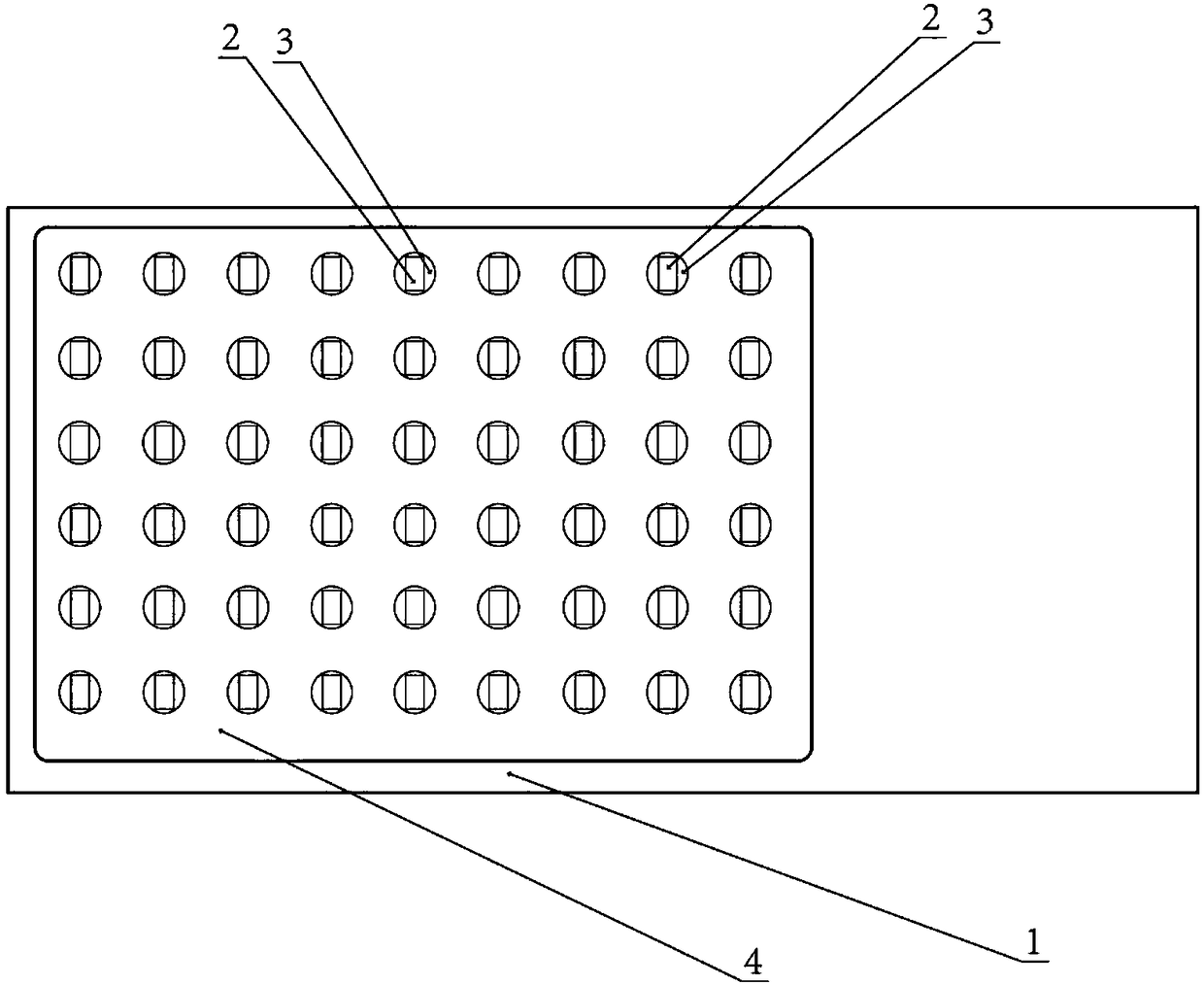

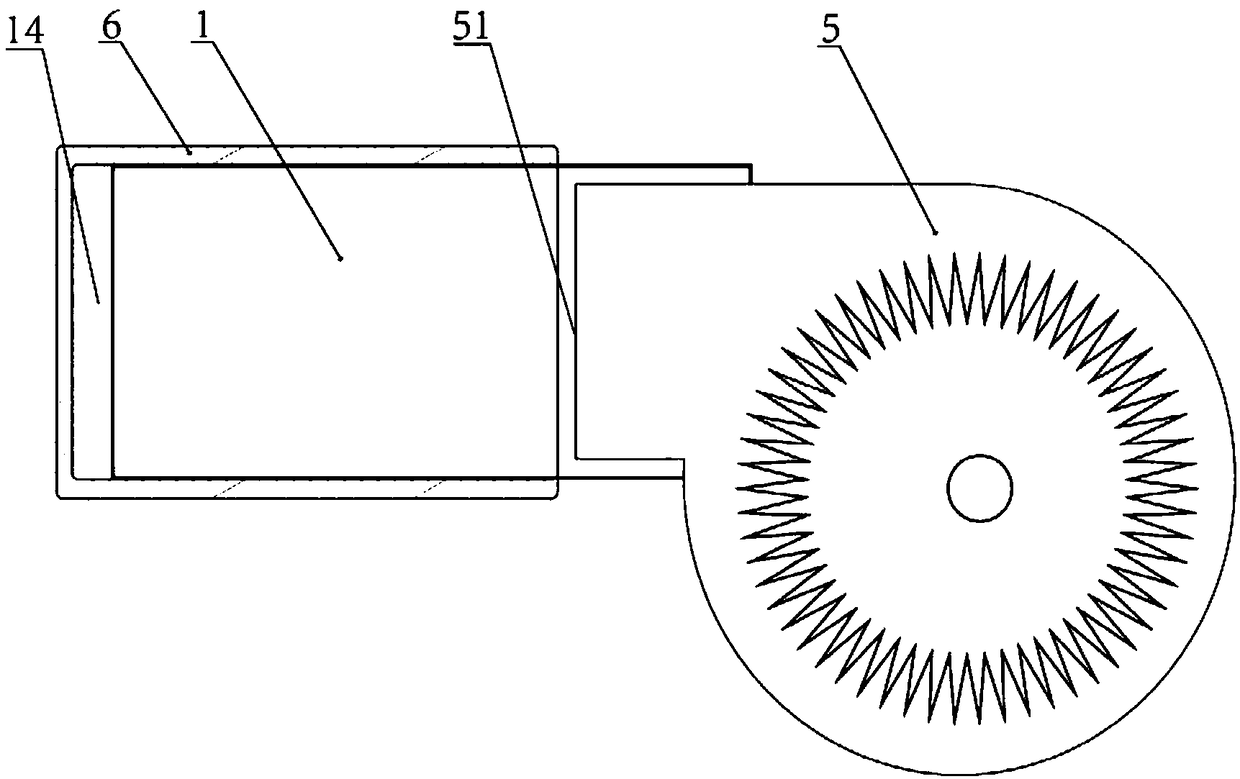

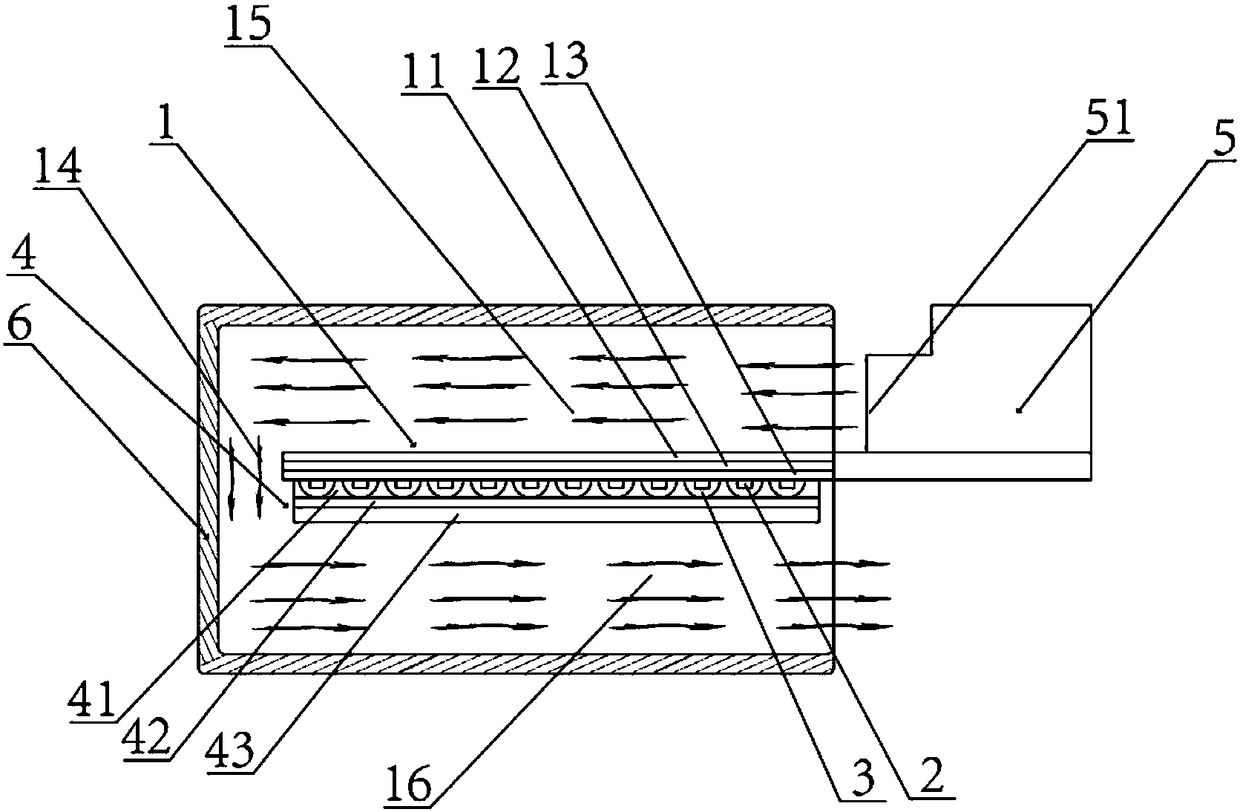

[0021] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

[0022] Such as Figure 1 to Figure 4 As shown, the double-sided light-emitting LED light source structure based on the COB packaging structure of the present invention includes a multilayer ceramic substrate 1, an LED chip array 2 arranged on the multilayer ceramic substrate 1, a silver glue conductive circuit, and a light-transmitting ceramic lens 3 , fluorescent adhesive layer 4, heat dissipation device 5 and heat dissipation lampshade 6, wherein:

[0023] The multilayer ceramic substrate 1 is a light-transmitting ceramic layer substrate made of nano-materials in the prior art. The multilayer ceramic substrate 1 includes a light-transmitting and pressure-resistant ceramic layer 11, a light-transmitting high-thermal-conductivity ceramic layer 12 and a light-transmitting fluorescent ceramic laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com