Preparation method of conductive material-doped nanometer piezoelectric composite thin film generator

A technology of piezoelectric composite and conductive materials, applied in nanotechnology for material and surface science, fabrication/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., capable of Solve the problems of insufficient output power and low piezoelectric coefficient, and achieve the effect of low cost, high piezoelectric coefficient and high voltage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

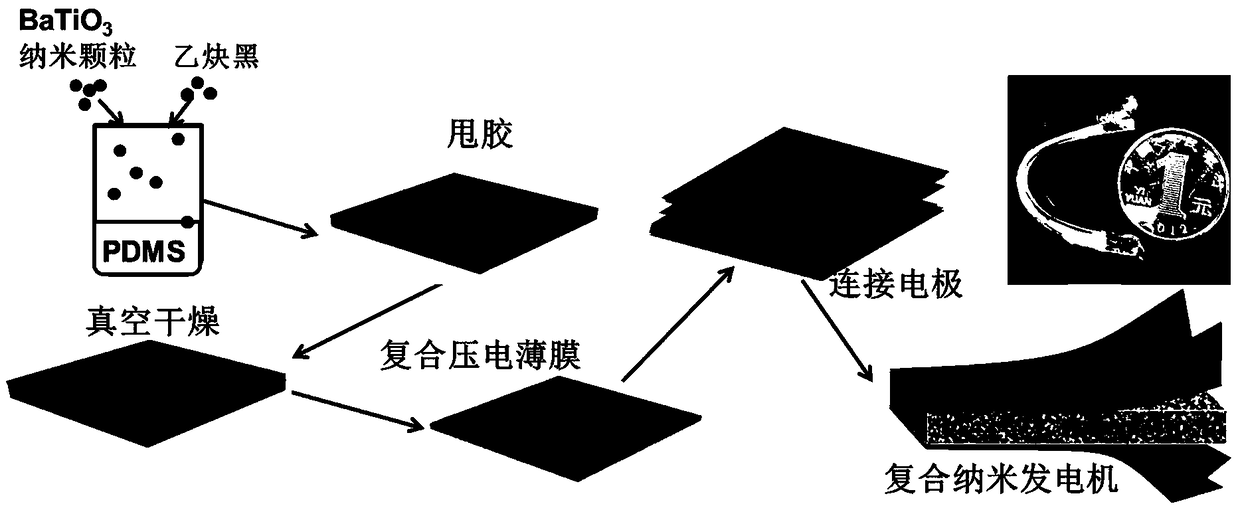

[0016] A method for preparing a nano piezoelectric composite film generator doped with conductive materials, the specific preparation steps are as follows:

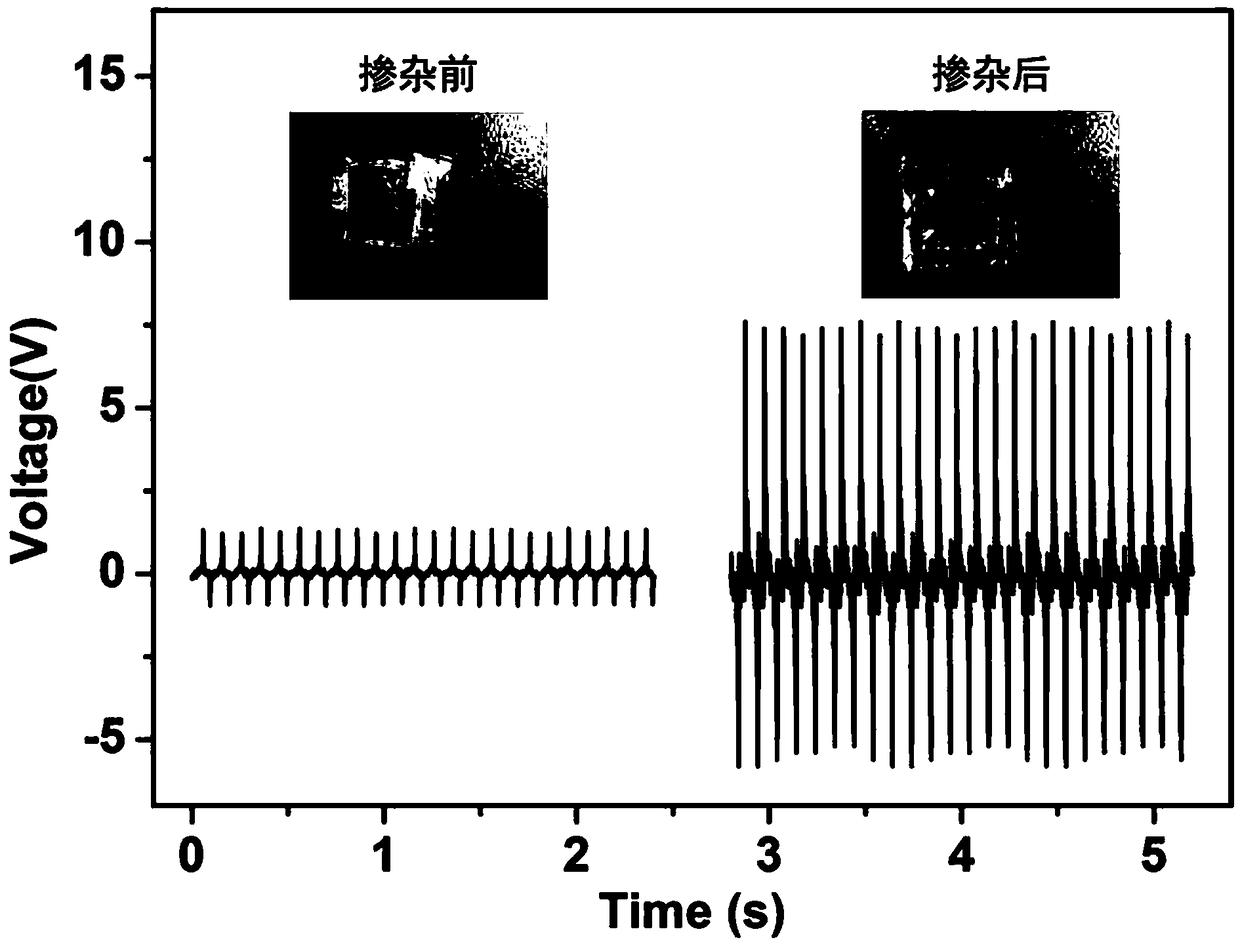

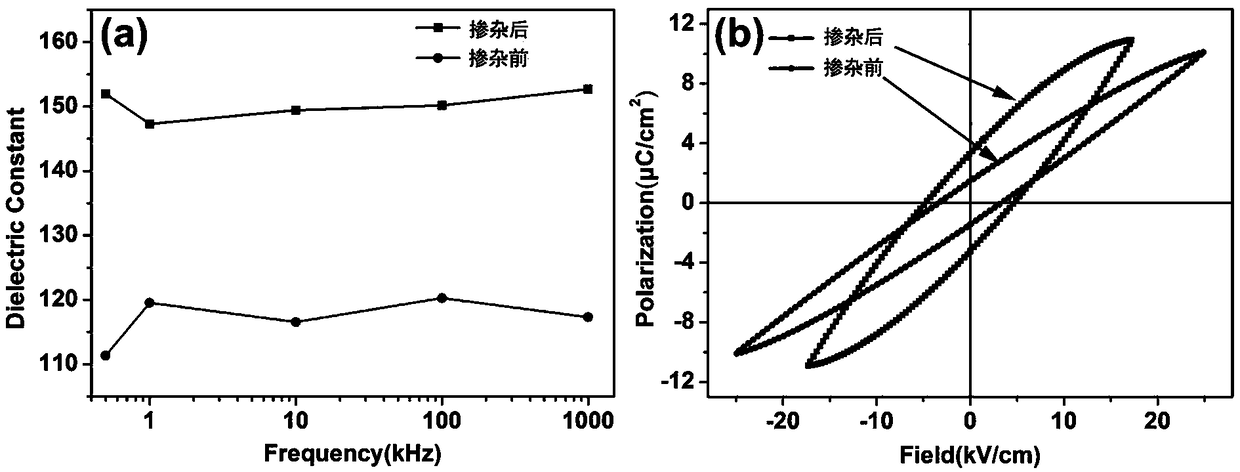

[0017] (1) Prepare the nano-piezoelectric composite solution doped with conductive materials: Weigh the PDMS main solvent and the hardening solvent with a balance, mix them evenly at a mass ratio of 10:1, and pour them into a beaker; then weigh them with a balance (including but not Limited to) piezoelectric materials such as lead zirconate titanate, zinc oxide, barium titanate, aluminum nitride, lead magnesium niobate, sodium niobate, potassium niobate, lithium niobate, etc. Conductive materials such as nanotubes are placed in the beaker. Put the beaker in a magnetic stirring water bath at a speed of 2500 r / min, seal the mouth of the beaker with plastic wrap, and stir for 1-1.5 hours to obtain a uniformly dispersed nano-piezoelectric composite solution. The mass ratio of piezoelectric material to PDMS is 0.1~7:10 (0.1:1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com