Production method of metal micro-needle array female die

A microneedle array and metal technology, applied in the directions of microneedles, needles, and pharmaceutical devices, can solve the problems of easy deformation of polymer female molds, difficult processing technology, and difficult precision control, and achieve easy mass replication and preparation. Microneedle array patch, low processing cost and stable physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

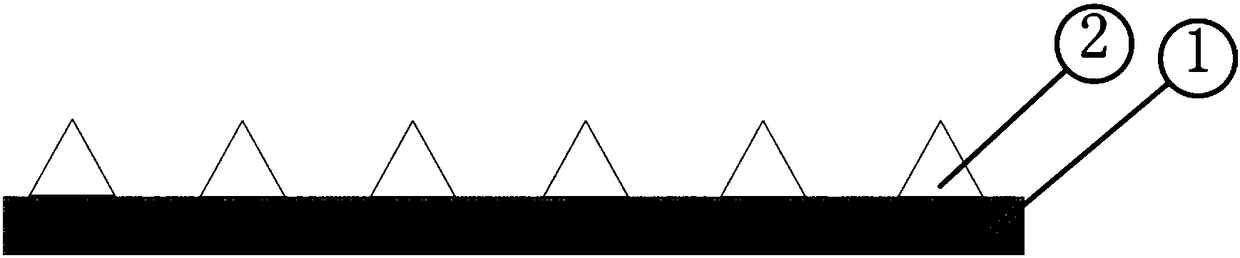

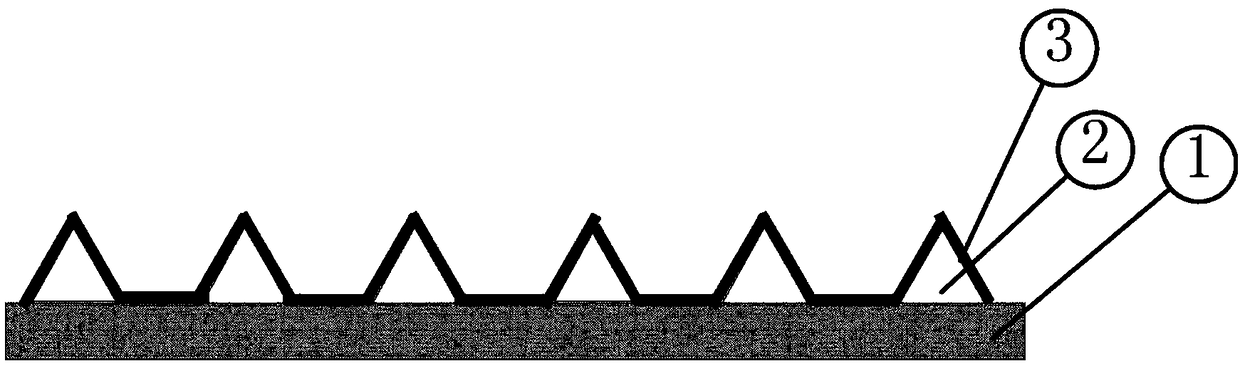

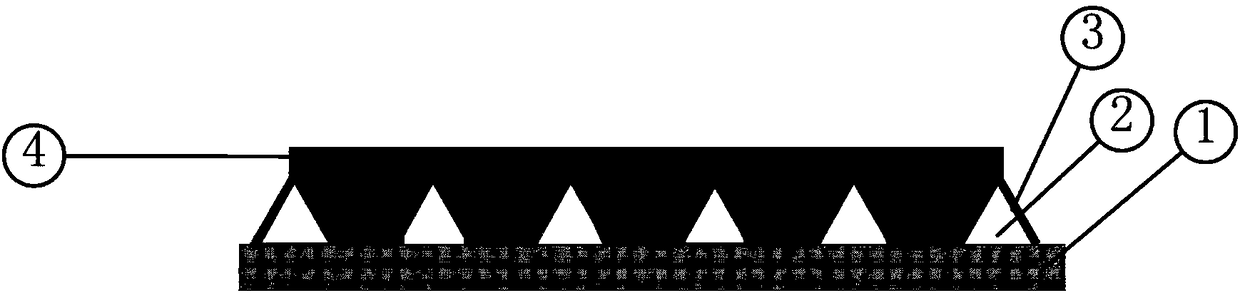

[0034] figure 1 It is a schematic diagram of the microneedle array male mold in the manufacturing process of the metal microneedle array female mold of the present invention; figure 2 It is a schematic diagram of the anti-adhesion layer and the metal seed layer coated on the surface of the microneedle array male mold in the metal microneedle array female mold process of the present invention; image 3 A schematic diagram of electroplating (or electroless plating or electroplating) on the surface of the microneedle array male mold coated with an anti-adhesion layer and a metal seed layer; Figure 4 It is a schematic diagram of the metal layer of the female mold coated with an adhesive layer in the process of the female mold of the metal microneedle array of the present invention; Figure 5 It is an overall schematic diagram of the reinforcement layer added in the metal microneedle array female mold process of the present invention; Image 6 It is a metal microneedle array female ...

Embodiment 2

[0064] In this embodiment, the preparation method of the microneedle array male mold is MEMS (Micro Mechanical Micro Electro Mechanical System). The material is various types of silicon substrates, with a thickness of 200μm~3000μm, a microneedle diameter of 0.001μm~5000μm, and a microneedle height of 0.001μm~10,000μm. The material of this embodiment is preferably a double-polished monocrystalline silicon wafer, the microneedle diameter is 200 μm, and the microneedle height is 300 μm.

[0065] The shape of the microneedle in this embodiment is a square pointed cone. In order to ensure the density of the microneedle array, the spacing between the microneedles in this embodiment is 400 μm.

[0066] The anti-adhesion layer of this embodiment is perfluoroalkoxy resin with a thickness of 100 nm.

[0067] The material of the metal seed in this embodiment is Cr / Cu, and the thickness is 30 / 80 nm.

[0068] In this embodiment, it is preferably Cu with a thickness of 2 mm.

[0069] This embodime...

Embodiment 3

[0092] The microneedle array male mold is prepared by ultra-precision mechanical method, the material is glass, such as: quartz glass, ordinary silicate glass, etc., the diameter of the microneedle is 0.001μm~5,000μm, and the height of the microneedle is 0.001μm~10,000μm. The material example of this embodiment selects ordinary silicate peeling, etc., the microneedle diameter is 50 μm, and the microneedle height is 150 μm.

[0093] The microneedle in this embodiment is a six-sided pointed cone.

[0094] The spacing between the microneedles in this embodiment is 150 μm.

[0095] The anti-adhesive layer in this embodiment is ethylene-tetrafluoroethylene copolymer with a thickness of 80 nm.

[0096] The material of the metal seed in this embodiment is Cr / Ti, and the thickness is 30 / 50 nm.

[0097] In this embodiment, the female mold metal layer is Ni with a thickness of 0.5 mm.

[0098] In this embodiment, the adhesive layer is selected from glass glue, with a thickness of 0.3 mm.

[0099] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com