Method for preparing abrasive-grade bauxite clinker from bauxite raw fine ore

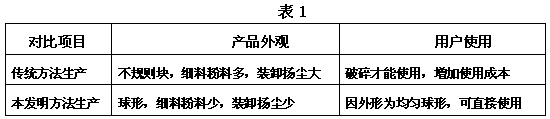

A technology of bauxite clinker and slag powder, which is applied in the field of bauxite clinker production, can solve the problems of poor comprehensive utilization of bauxite resources, high production costs, and low resource utilization. Achieve the effect of avoiding secondary dust pollution, good product particle size and low raw material price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1. A kind of method utilizing bauxite raw ore powder to prepare abrasive grade bauxite clinker, comprises the following steps:

[0028] a. Coarsely crushing the bauxite raw meal to a coarse material with a particle size of less than 60 mm to obtain product A;

[0029] b. Sieve product A through a 10mm sieve to obtain product B under the sieve;

[0030] C, spray the binding agent into the product B, and mix well to get the product C; the addition of the binding agent is 6% of the weight of the product B; the binding agent is a mixture of water glass and water, wherein The content of water glass is 40%;

[0031] d, making product C into a spherical shape with a particle diameter of 30mm, i.e. product D;

[0032] e. Dry product D to obtain product E;

[0033] f. Calcining product E at 1200° for 2 hours, then cooling.

[0034] In the aforementioned step c, the modulus of the water glass is greater than 2.8, and the specific gravity is greater than or equal to 1...

Embodiment 2

[0037] Example 2. A kind of method utilizing bauxite raw ore powder to prepare abrasive grade bauxite clinker, comprises the following steps:

[0038] a. Coarsely crushing the bauxite raw meal to a coarse material with a particle size of less than 60 mm to obtain product A;

[0039] b. Sieve product A through an 8mm sieve to obtain product B under the sieve;

[0040] C, spray the binding agent into the product B, and mix well to get the product C; the addition of the binding agent is 4% of the weight of the product B; the binding agent is a mixture of water glass and water, wherein The content of water glass is 20%;

[0041] d, the product C is made into a spherical shape with a particle diameter of 8mm, i.e. the product D;

[0042] e. Dry product D to obtain product E;

[0043] f. Calcining product E at 1150° for 1.5h, then cooling to obtain it.

[0044] In the aforementioned step c, the modulus of the water glass is greater than 2.8, and the specific gravity is greater ...

Embodiment 3

[0046] Example 3. A kind of method utilizing bauxite raw ore powder to prepare abrasive grade bauxite clinker, comprises the following steps:

[0047] a. Coarsely crushing the bauxite raw meal to a coarse material with a particle size of less than 60 mm to obtain product A;

[0048] b. Sieve product A through a 10mm sieve to obtain product B under the sieve;

[0049] C, spray the binding agent into the product B, and mix well to get the product C; the addition of the binding agent is 8% of the weight of the product B; the binding agent is a mixture of water glass and water, wherein The content of water glass is 45%;

[0050] d, making product C into a spherical shape with a particle diameter of 40mm, i.e. product D;

[0051] e. Dry product D to obtain product E;

[0052] f. Calcining product E at 1250° for 3.5 hours, then cooling to obtain it.

[0053] In the aforementioned step c, the modulus of the water glass is greater than 2.8, and the specific gravity is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com