Resin composition and adhesive and protection film formed thereby

A resin composition and resin technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of bonding force affecting the performance of protective films, etc., to meet long-term application requirements, excellent performance, improve The effect of bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

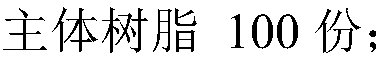

[0042] This embodiment provides a resin composition, which comprises the following components in parts by weight:

[0043] 100 parts of main resin, 1 part of adduct (curing agent) of toluene diisocyanate and trimethylolpropane, 0.01 part of dibutyltin diacetate (catalyst), 100 parts of ethyl acetate (solvent);

[0044] Among them, the main resin includes polyurethane prepolymer containing urethane groups (resin A for short) and polyol resin (resin B for short), the mass ratio of resin A and resin B is 1:5, and group A in the main resin It is divided into a polyurethane prepolymer containing 2 terminal hydroxyl groups and an average molecular weight of 8000, and resin B is a polyol containing 3 terminal hydroxyl groups and an average molecular weight of 8000.

[0045] This embodiment also provides an adhesive, which includes the above-mentioned resin composition, by mixing the main resin, solvent and catalyst weighed in proportion under mechanical stirring, then adding a curing...

Embodiment 2

[0047] This embodiment provides a resin composition, which comprises the following components in parts by weight:

[0048] 100 parts of main resin, 3 parts of hexamethylene diisocyanate trimer (curing agent), 0.1 part of bismuth isooctanoate (catalyst), 50 parts of toluene (solvent);

[0049] Among them, the main resin includes polyurethane prepolymer containing urethane groups (resin A for short) and polyol resin (resin B for short), the mass ratio of resin A and resin B is 1:3, and group A in the main resin It is divided into a polyurethane prepolymer containing 3 terminal hydroxyl groups and an average molecular weight of 10,000. Resin B is a polyol containing 2 terminal hydroxyl groups and an average molecular weight of 4,000.

[0050]This embodiment also provides an adhesive, which includes the above-mentioned resin composition, by mixing the main resin, solvent and catalyst weighed in proportion under mechanical stirring, then adding a curing agent and stirring evenly, u...

Embodiment 3

[0052] This embodiment provides a resin composition, which comprises the following components in parts by weight:

[0053] 100 parts of main resin, 5 parts of 1,5-naphthalene diisocyanate and trimethylolpropane adduct (curing agent), 1 part of dibutyltin dilaurate (catalyst), 150 parts of butyl acetate (solvent);

[0054] Among them, the main resin includes polyurethane prepolymer containing urethane groups (resin A for short) and polyol resin (resin B for short), the mass ratio of resin A and resin B is 1:10, and group A in the main resin Divided into a polyurethane prepolymer containing 3 terminal hydroxyl groups and an average molecular weight of 12,000. Resin B is a polyol containing 3 terminal hydroxyl groups and an average molecular weight of 6,000.

[0055] This embodiment also provides an adhesive, which includes the above-mentioned resin composition, by mixing the main resin, solvent and catalyst weighed in proportion under mechanical stirring, then adding a curing ag...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap