Wind electric field collector line leading wire spraying de-icing method and system

An anti-icing technology for power-collecting lines, applied in the installation of cables, electrical components, overhead installations, etc., can solve the problems of icing hazards on transmission lines, resistance loss and heat generation, poor anti-icing effect, etc., and achieve excellent anti-pollution flashover Performance, elimination of cleaning, effect of preventing bird damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

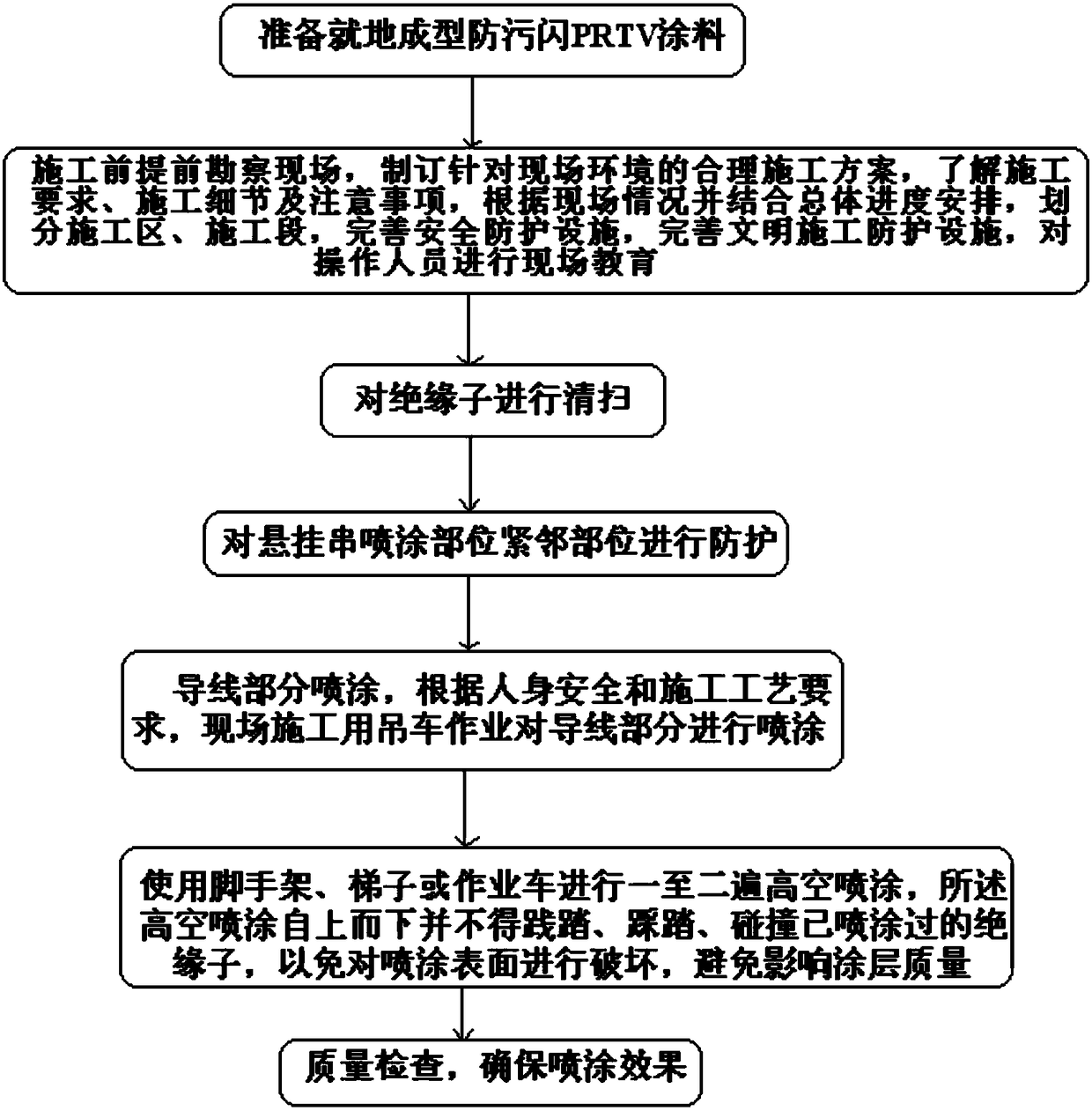

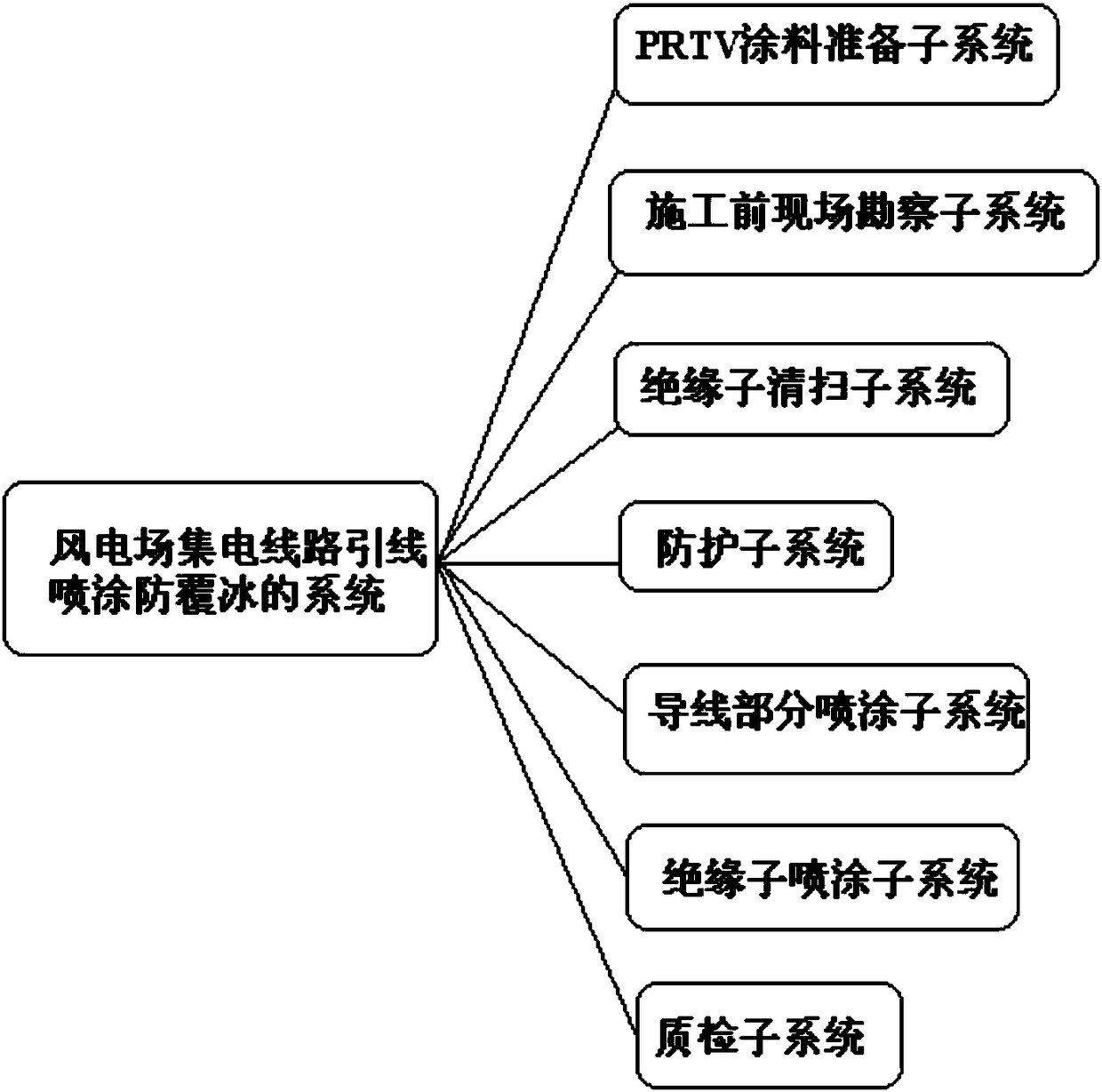

Method used

Image

Examples

Embodiment Construction

[0068] The project background of this example is: the interior of the Pinglu wind farm is mountainous terrain, with an altitude of 800 meters to 1787 meters. In 2017, the Pinglu wind farm was severely icing, which caused the line to trip, and the icing caused the collector line, tower overload, and insulator ice flash , causing a major threat to the collector line. In January 2017, the ice-covered line II of the Pinglu wind field tripped due to the ice-covered line. The ice-covered tower material was deformed at the same time, and the conductor of the 8# iron tower was broken. are closely related. Severe icing can easily lead to tower collapse and disconnection, and the resulting power loss will be unpredictable. For this reason, a new method is developed and the construction is carried out in strict accordance with the "Normal Temperature Curing Silicone Rubber Anti-fouling Flashover Coating for Insulators" (DL / T627-2004) promulgated by the National Development and Reform Com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com