Polyethylene glycol uricase freeze drying powder and preparation method thereof

A technology of uric acid oxidase and pegylation, applied in biochemical equipment and methods, oxidoreductase, freeze-drying and transportation, etc., can solve the problems of non-shaking, non-freezing, unsuitable for long-distance transportation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] According to the isoelectric point of pegylated urate oxidase, the appropriate formulation pH is selected.

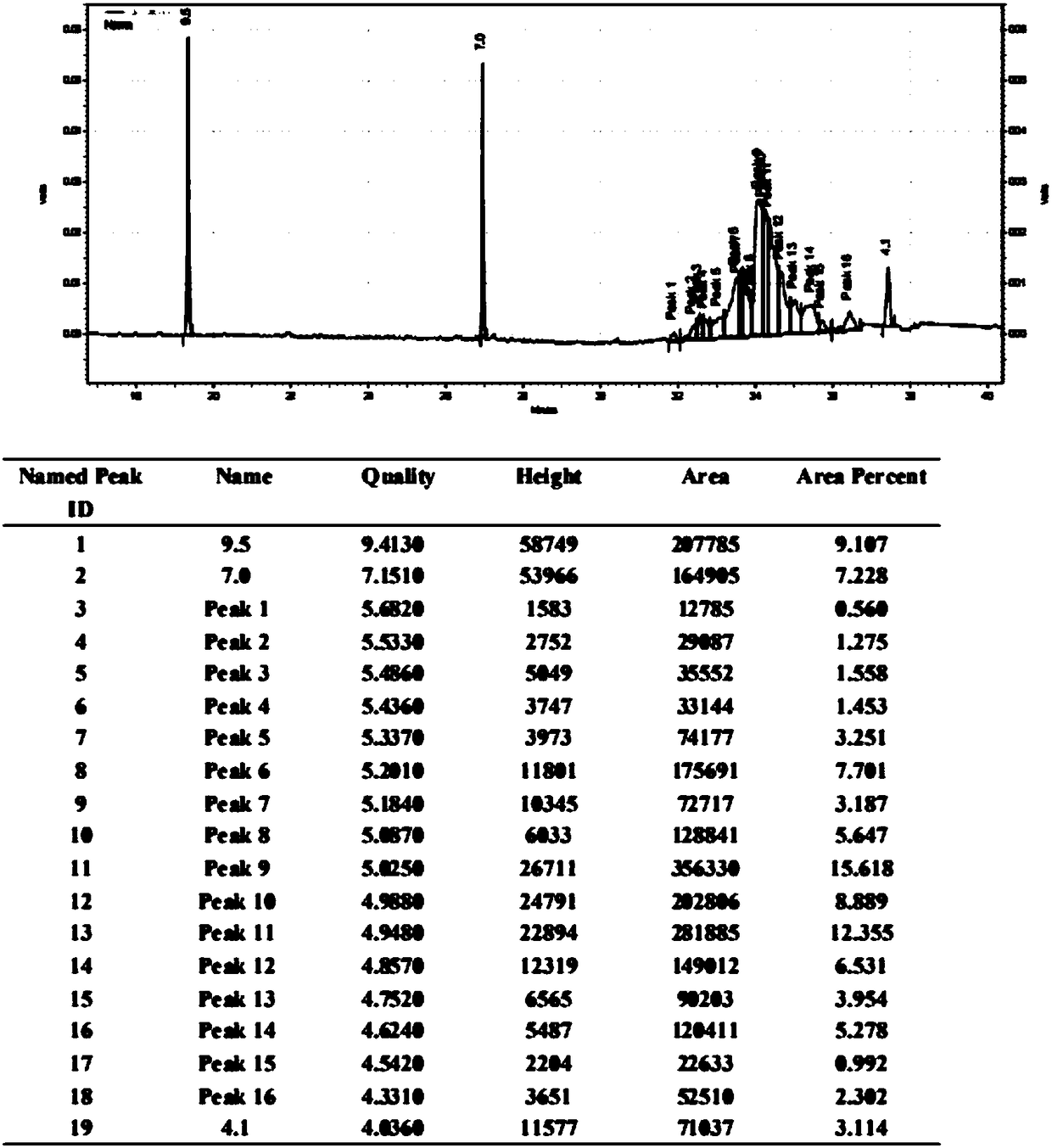

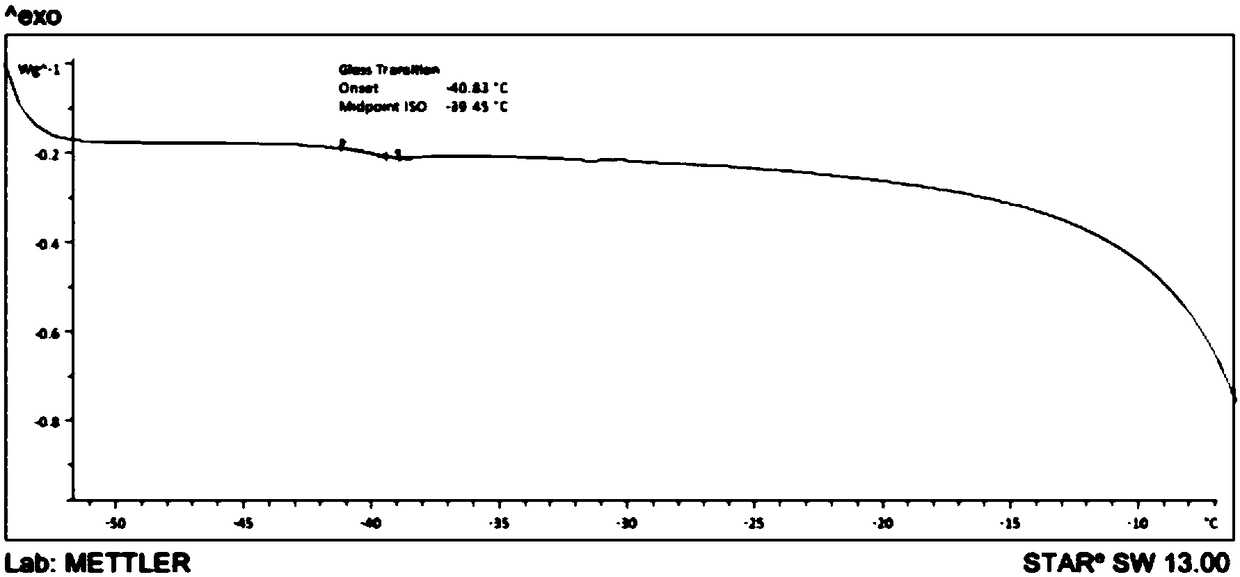

[0056] The isoelectric point of pegylated urate oxidase was detected by capillary isoelectric focusing (cIEF). figure 1 ,pass figure 1 According to the analysis, the isoelectric point of pegylated urate oxidase is between 4.0-6.0, and the pH value of the preparation is designed according to the result, and the pH value range is designed between 6.0-10.

[0057] Experiments were carried out by designing the following 8 buffer systems with different pH values, adding 2.5mg / ml pegylated urate oxidase to each formulation, and detecting the change of activity after accelerating at 30°C for 1 hour.

[0058] Table 2. Retention activity of pegylated urate oxidase after accelerated experiment under different pH conditions

[0059]

[0060]

[0061] Through accelerated experiments on 9 prescriptions at 30°C, the activity of pegylated urate oxidase after the acceler...

Embodiment 2

[0063] Through the screening of different preparation prescriptions, the preparation prescription ingredients suitable for pegylated urate oxidase are selected.

[0064] Lyophilized formulations generally contain bulking ingredients to increase the amount of solid material as well as protectants, antifreezes and other stabilizers to protect the active ingredient from destruction during and after lyophilization.

[0065] Among the lyoprotectants, we prefer carbohydrates as protectants, because carbohydrates function as cryoprotectants during freezing and can also function as dehydration protectants during drying and dehydration. Sugars are divided into reducing sugars and non-reducing sugars. During the freeze-drying process, both reducing sugars and non-reducing sugars can have a good protective effect, but the presence of reduced sugars during freeze-drying storage The lyophilized product undergoes Maillard reaction, which eventually causes the lyophilized product to deterior...

Embodiment 3

[0097] Select the appropriate buffer concentration range for the preparation formulation.

[0098] Design 8 different buffer solution formulas for experiments, add 2.5mg / ml pegylated urate oxidase to each formula, detect the aggregation precipitation and activity decrease percentage of pegylated urate oxidase after repeated freezing and thawing, the results are shown in the table 11.

[0099] Table 11. Repeated freeze-thaw experiments of pegylated urate oxidase with different buffer concentrations

[0100] Numbering

[0101] Through the comparison of different buffer concentrations, it can be seen that due to the inherent characteristics of pegylated urate oxidase products, too low buffer concentration cannot provide effective protection for frozen samples, and too high It will affect the sample activity, so the optional buffer range of the pegylated urate oxidase preparation is 20-100mM phosphate buffer, preferably 30-60mM phosphate buffer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com