A pulse power supply for wire electric discharge cutting and its control method

A technology of pulse power supply and electric spark wire, applied in the direction of program control, computer control, general control system, etc., to achieve the effect of increasing system switching frequency, flexible control algorithm, improving power density and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The solution of the present invention will be further described in detail below in conjunction with the accompanying drawings.

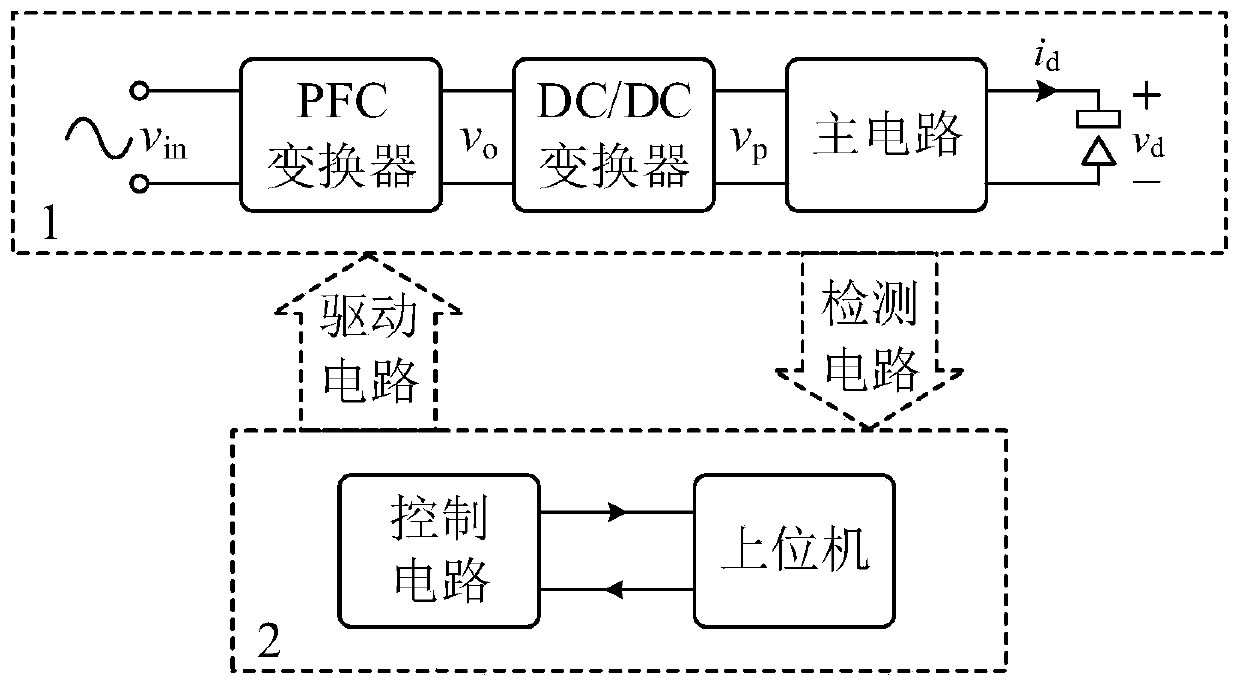

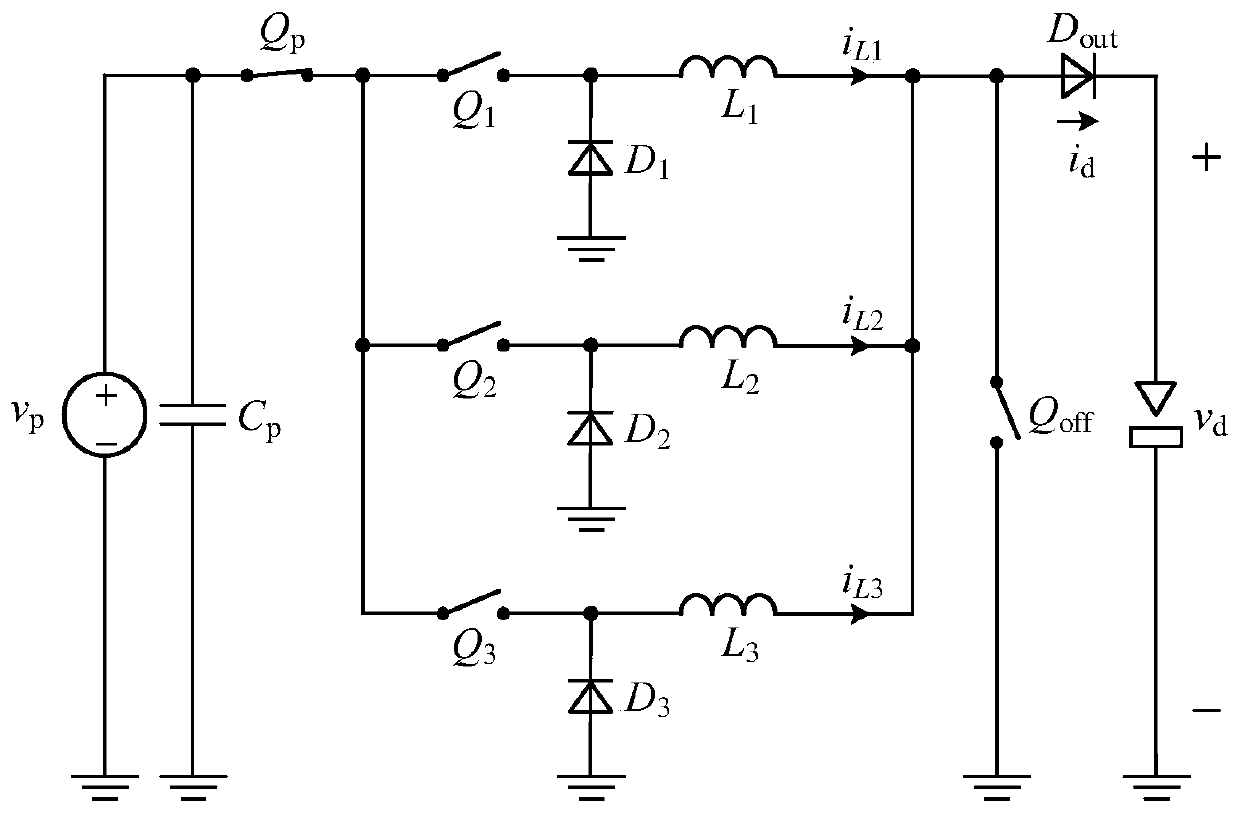

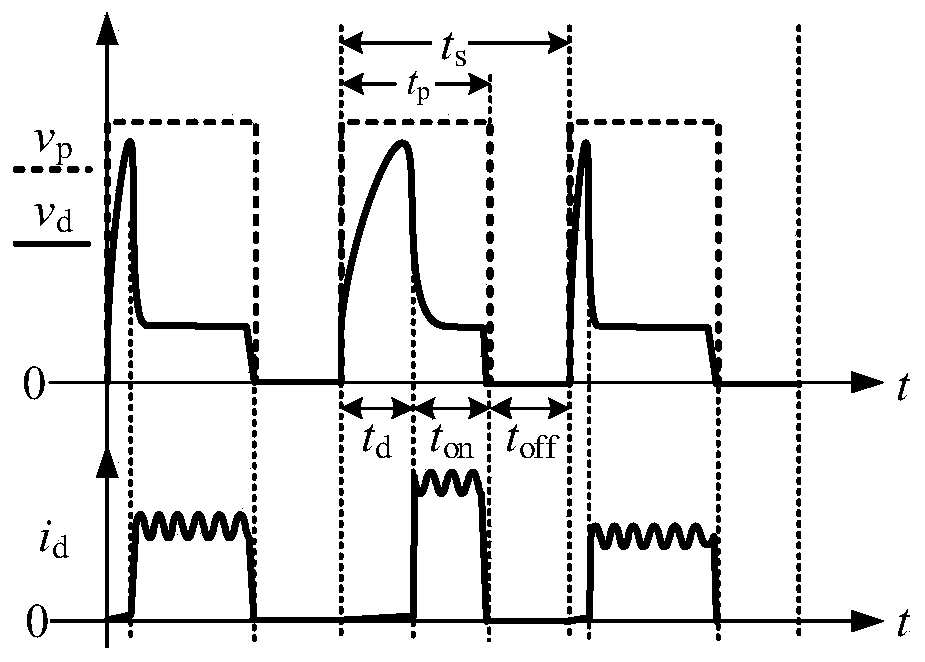

[0019] Such as figure 1 As shown, the wire electric discharge cutting pulse power supply includes an AC power supply, a PFC converter, a DC / DC converter, a main circuit, a detection circuit, a drive circuit, a control circuit and a host computer, wherein the AC power supply outputs an AC voltage, which passes through the PFC converter, After the DC / DC converter, output adjustable DC voltage to supply power to the main circuit; the main circuit provides unipolar voltage to the gap; the detection circuit collects the voltage and current of the PFC converter, DC / DC converter, the main circuit and the gap, and transmits To the control circuit; the control circuit outputs a control signal, and after being amplified by the drive circuit, drives the on-off of the PFC converter, DC / DC converter and main circuit switch tube to control the PFC converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com