Method for preparing potassium mineral-enriched soil repairing material, potassium mineral-enriched soil repairing material prepared by using method and application

A soil remediation and mineral technology, applied in the direction of soil conditioning materials, restoration of contaminated soil, fertilization methods, etc., can solve the problems of long repair period, ineffective effect, secondary pollution, etc., achieve passivation activity, and simple preparation method Effective, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1: The potassium-rich mineral-based repair material was prepared by using leucite as raw material after heat treatment and hydrothermal activation treatment, and the repair experiment of contaminated soil was carried out.

[0026] Mix 1000g of leucite with 800g of quicklime, 200g of magnesium sulfate, and 30g of sodium chloride, grind it to a size below 200 mesh, heat treat at 1100°C for 1.5h, and obtain 1850g of heat-treated material. Add 1500g of water to the heat-treated material and add sulfuric acid to adjust the pH value to 8-9, heat to 240°C for hydrothermal activation treatment, filter and dry to obtain 1935g of potassium-rich mineral-based soil restoration material. See Table 1 for the ingredient content of raw materials, and Table 2 for the ingredient content of the product.

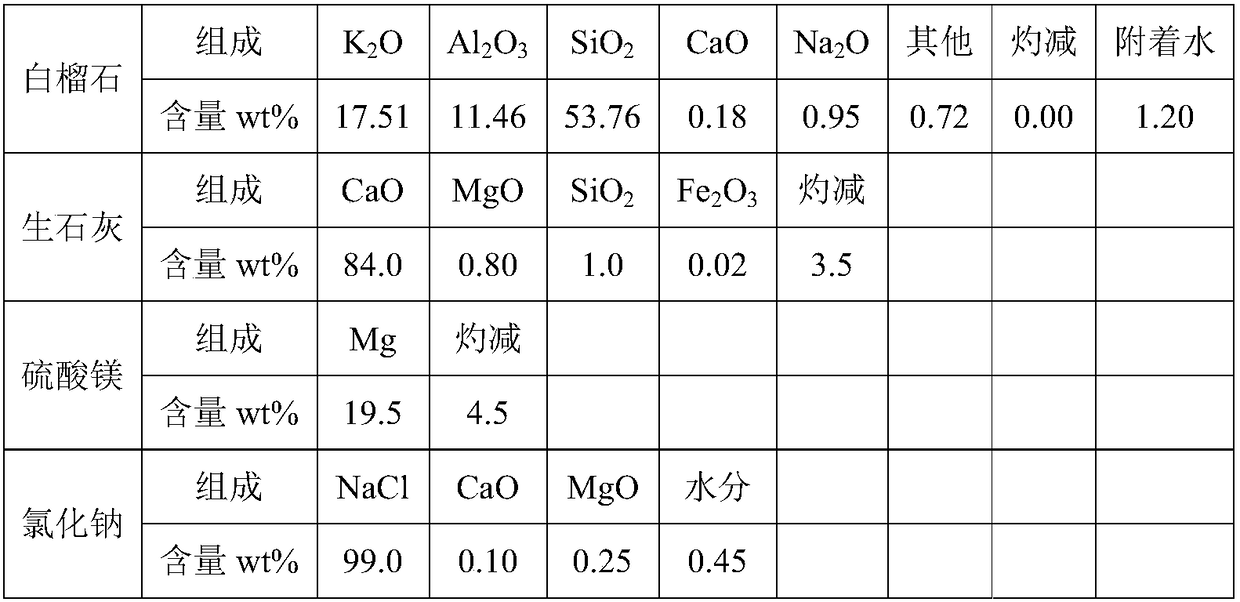

[0027] Table 1 Composition content list of raw and auxiliary materials

[0028]

[0029] *Loss on ignition refers to loss on ignition.

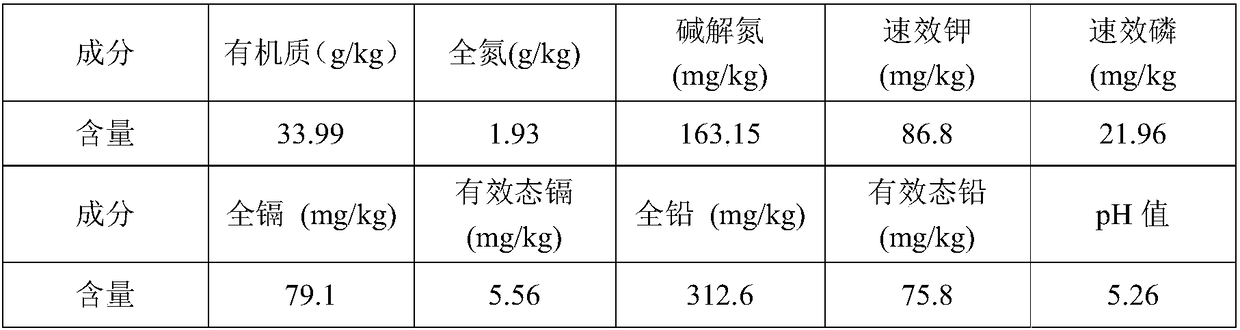

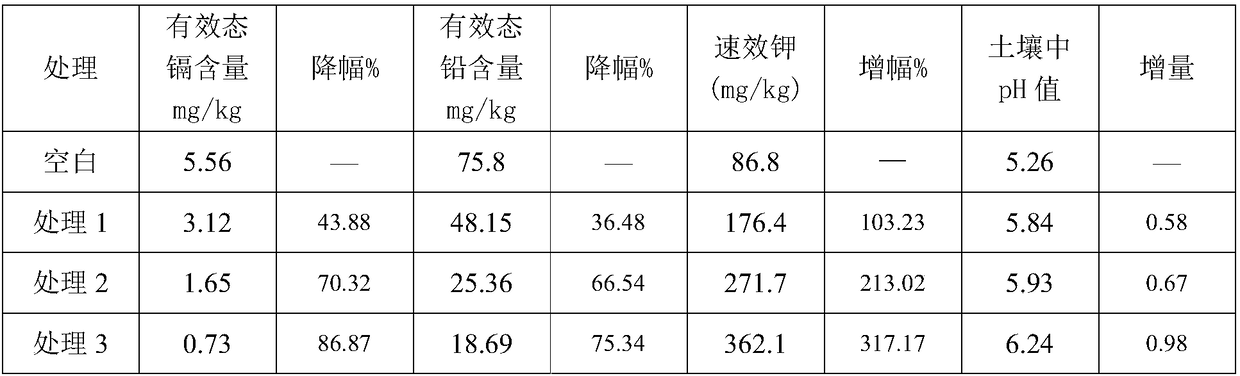

[0030] Table 2 ICP test data table o...

Embodiment 2

[0039] Example 2: Using feldspar as a raw material, after heat treatment and hydrothermal activation treatment, potassium-rich mineral-based restoration materials were prepared by firing, and a field restoration experiment of contaminated soil was carried out.

[0040] Mix 150kg of feldspar ore with 240kg of limestone, 80kg of magnesium carbonate, and 12kg of sodium sulfate and grind them to a size below 200 mesh. Heat-treat at 1300°C for 2 hours to obtain 280kg of heat-treated material. Add water according to the ratio of 1:1 between water and heat-treated material, add phosphoric acid to adjust the pH value to 7-8, heat to 200°C for hydrothermal activation treatment, and dry to obtain 265kg of potassium-rich mineral-based soil restoration material. See Table 5 for the ingredient content of raw materials, and Table 6 for the ingredient content of the product.

[0041] Table 5 Composition content table of raw and auxiliary materials

[0042]

[0043] *Loss on ignition refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com