A kind of preparation method and application of high temperature resistant lye waterborne polyurethane coating

A technology of water-based polyurethane and high temperature resistance, which is applied in the field of water-based polyurethane, which can solve the problems of easy dispersion of ink, poor printability, poor mechanical properties, etc., and achieve the effects of improving poor medium resistance, improving gloss, and improving gloss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

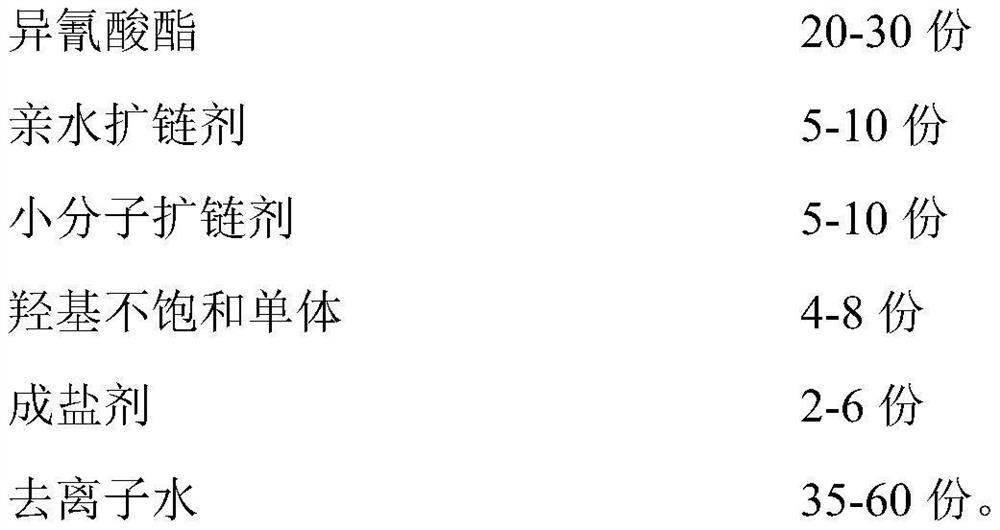

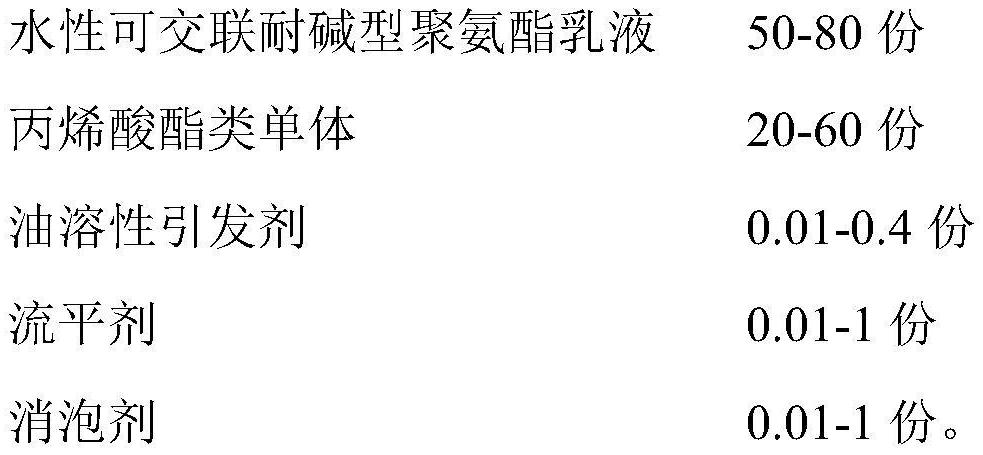

Method used

Image

Examples

Embodiment 1

[0034] In this embodiment, the high-temperature-resistant lye water-based polyurethane coating is first introduced into the polyurethane with epoxy resin and double bonds to realize copolymerization with acrylate monomers, and the high-temperature-resistant lye is prepared by self-emulsification of the matrix resin in water Water-based polyurethane emulsion, a high-temperature alkali-resistant water-based polyurethane coating obtained after adding additives, the preparation process specifically includes the following steps:

[0035] 1. At 110°C, vacuum dewater 12 parts by mass of epoxy resin EP44 and 37 parts by mass of polycarbonate diol (Mn=2000) in the container for 1 hour; lower the temperature of the system to 85°C, and add 23 parts by mass Parts of isophorone isocyanate was reacted with 8 parts by mass of dimethylolpropionic acid for 2 hours, then 6 parts by mass of 1,4 butanediol was added to continue the reaction for 1 hour, and finally the temperature was lowered to 60...

Embodiment 2

[0042] In this embodiment, the high-temperature-resistant lye water-based polyurethane coating is first introduced into the polyurethane with epoxy resin and double bonds to realize copolymerization with acrylate monomers, and the high-temperature-resistant lye is prepared by self-emulsification of the matrix resin in water Water-based polyurethane emulsion, a high-temperature alkali-resistant water-based polyurethane coating obtained after adding additives, the preparation process specifically includes the following steps:

[0043]1. At 110°C, vacuum dewater 18 parts by mass of epoxy resin EP12 and 25 parts by mass of polycarbonate diol (Mn=1000) in the container for 1 hour; lower the temperature of the system to 80°C, and add 20 mass parts Parts of isophorone isocyanate was reacted with 7 parts by mass of dimethylolpropionic acid for 2 hours, then 6 parts by mass of 1,4 butanediol was added to continue the reaction for 1 hour, and finally the temperature was lowered to 60°C, ...

Embodiment 3

[0050] In this embodiment, the high-temperature-resistant lye water-based polyurethane coating is first introduced into the polyurethane with epoxy resin and double bonds to realize copolymerization with acrylate monomers, and the high-temperature-resistant lye is prepared by self-emulsification of the matrix resin in water Water-based polyurethane emulsion, a high-temperature alkali-resistant water-based polyurethane coating obtained after adding additives, the preparation process specifically includes the following steps:

[0051] 1. At 110°C, vacuum dewater 13 parts by mass of epoxy resin EP44 and 40 parts by mass of polycarbonate diol (Mn=1000) in the container for 1 hour; lower the temperature of the system to 80°C, and add 18 mass parts Parts of hexamethylene diisocyanate reacted with 6 parts by mass of dimethylolpropionic acid for 3 hours, then added 6 parts by mass of 1,4 butanediol to continue the reaction for 1 hour, and finally lowered the temperature to 60°C, and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com