Phloretin preparation method

A technology of phloretin and phloretin, which is applied in the field of preparation of phloretin, can solve the problems of high cost and complicated preparation process, and achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Phloretin

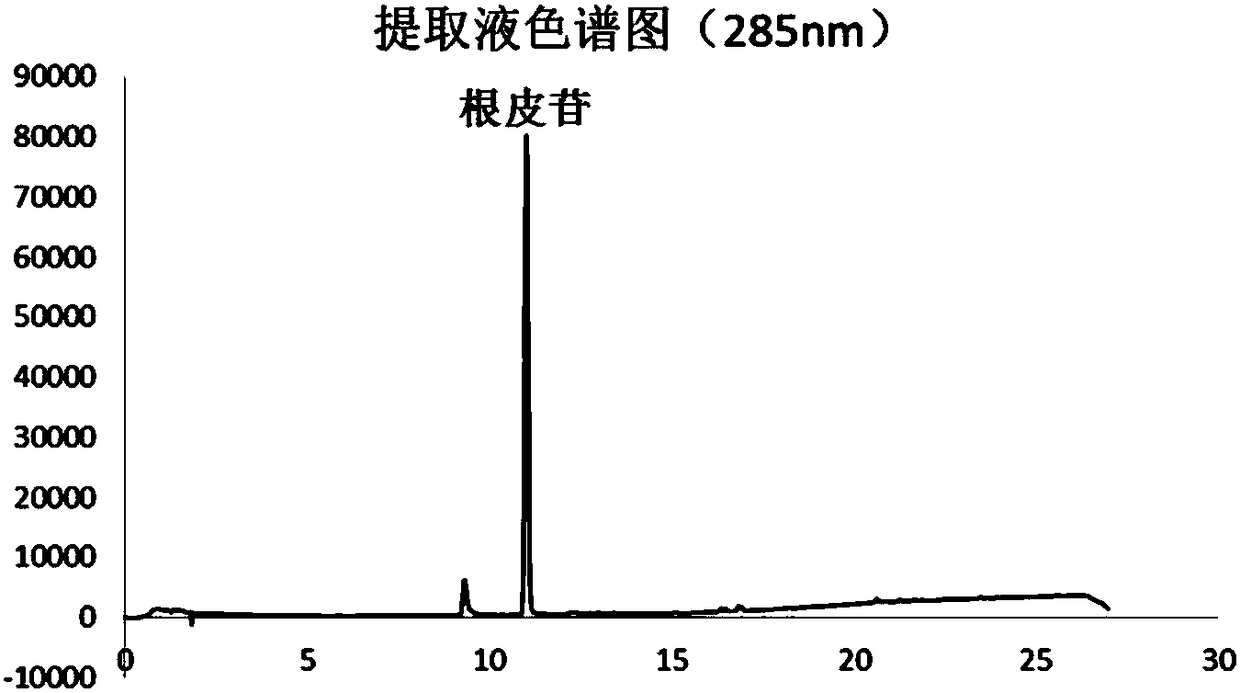

[0029] (1) Boil the leaves of Forestia wushanensis in water for 15 minutes to obtain a boiled liquid with a concentration of phloridzin of 6 mg / mL, and perform HPLC analysis after diluting the boiled liquid 30 times, the results are as follows figure 1 shown by figure 1 It can be seen that the content of phlorizin in the extract is rich and the impurities are less;

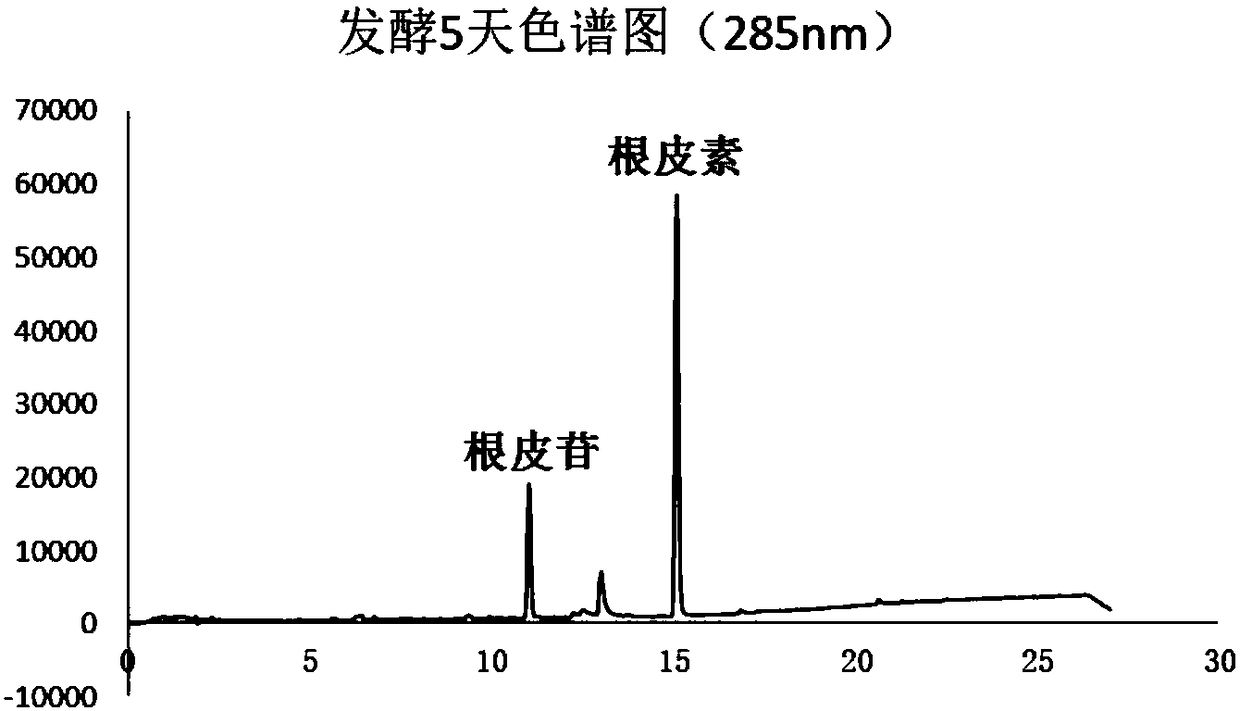

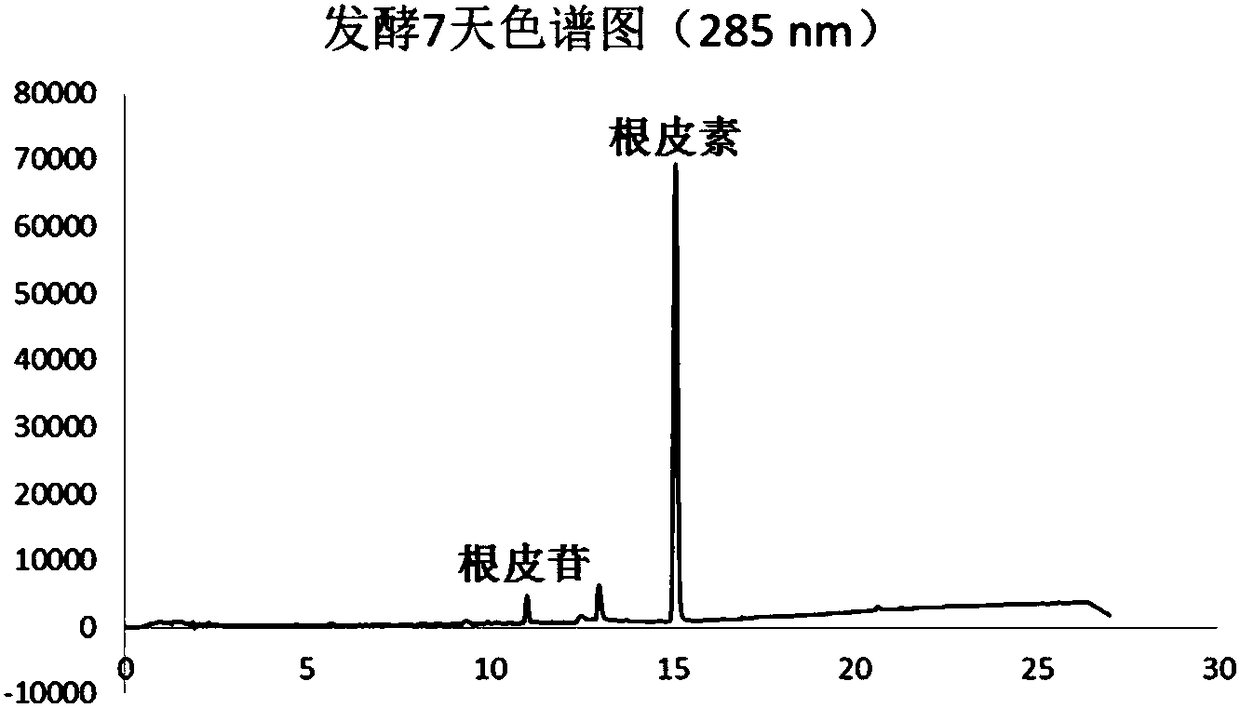

[0030] (2) Make the spore concentration 6×10 by 1% inoculation amount 7 The Trichoderma viride spore suspension of CFU / mL was inoculated in the poached liquid obtained in step (1), then fermented at 28°C, and when fermented for 5 days, an appropriate amount of fermented liquid was diluted 30 times and then analyzed by high performance liquid chromatography , the result is as figure 2 shown by figure 2 It can be seen that after 5 days of fermentation, most of the phloridzin in the extract has been converted into phloretin; then when fermented for 7 days, an appropriate amount of fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com