Efficient spraying machine special for machinery-picked cotton

A sprayer and machine cotton picking technology, applied in the application, catching or killing device of insects, animal husbandry and other directions, can solve the problems of low pesticide spraying efficiency, low operation level, small air volume of air curtain, etc. Harvesting operation, saving material and manpower, reducing the effect of grain spectrum range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

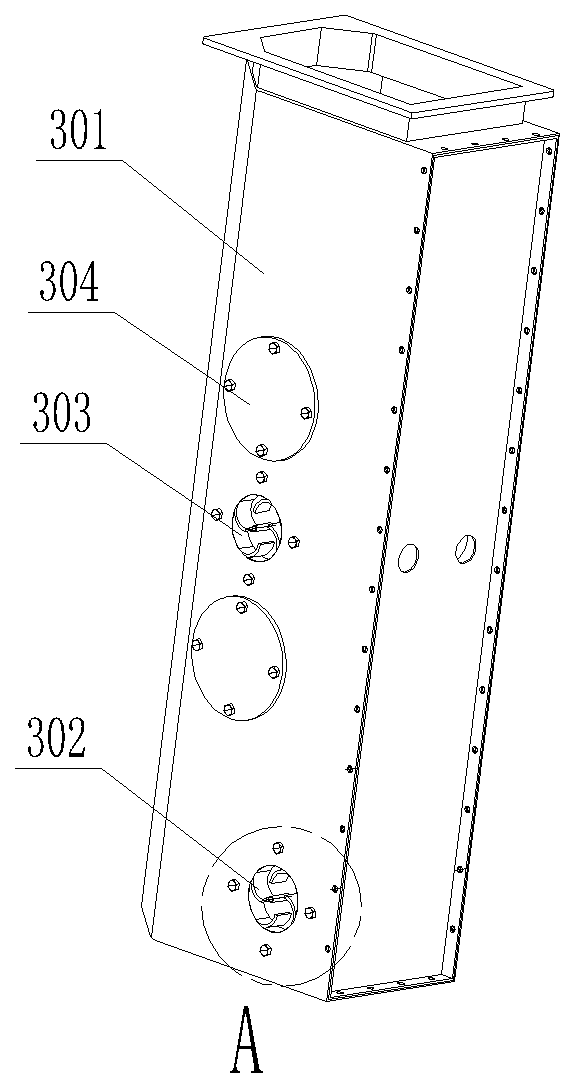

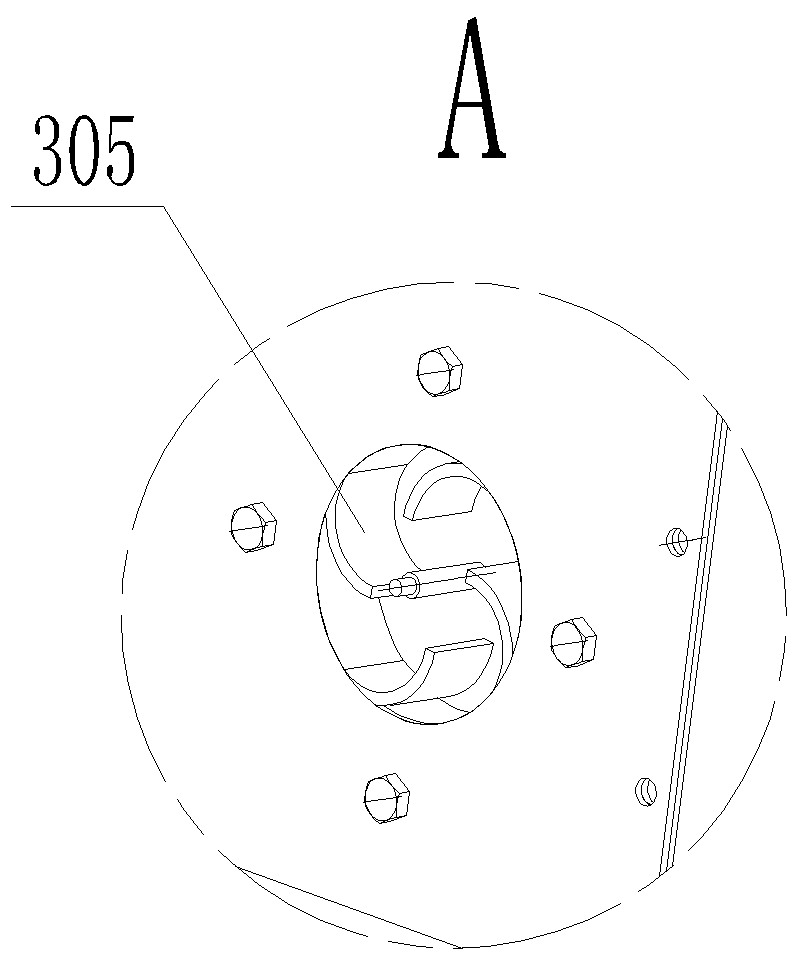

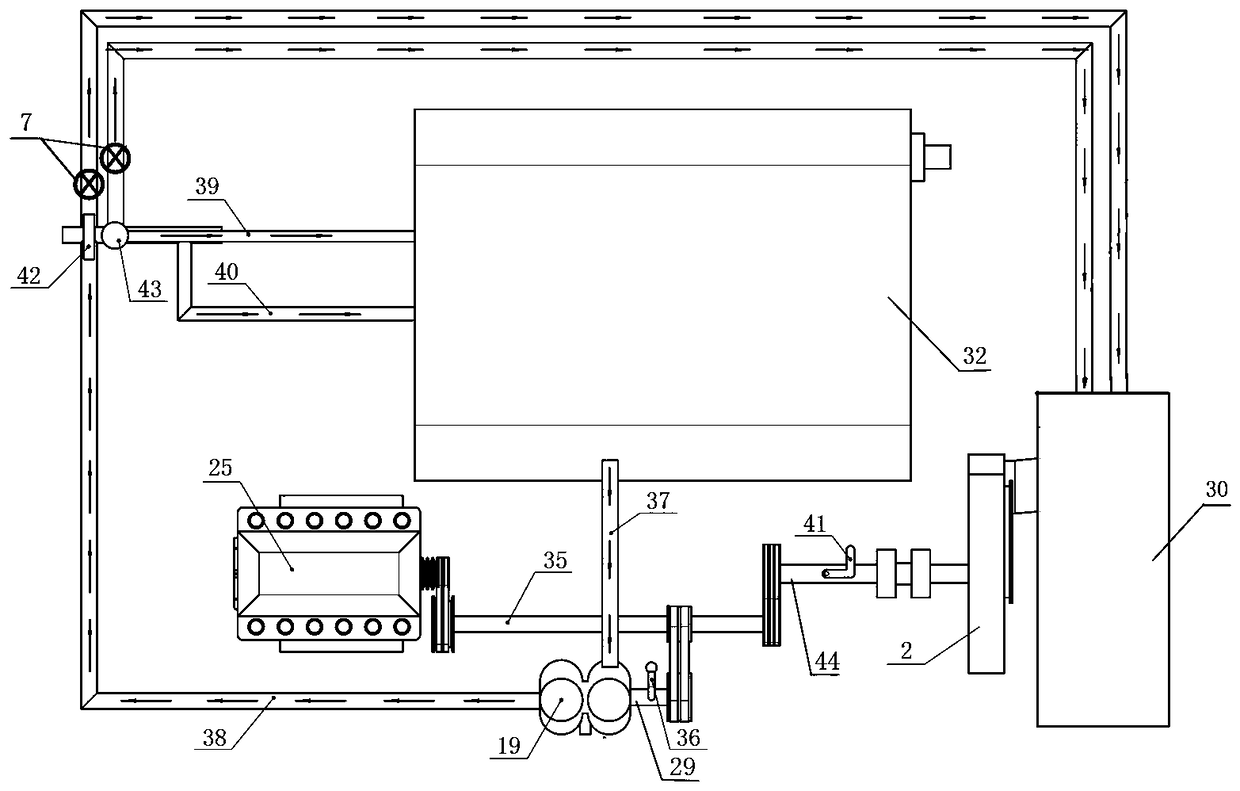

[0038] as attached Figure 1-5As shown, a special high-efficiency sprayer for machine picking cotton includes a car body, a walking wheel 62 arranged under the car body, a grain divider installed on the outside of the walking wheel 62, and a grain divider arranged on the car body and positioned directly in front of the walking wheel 62. The camera; the car body includes a vehicle frame 61, a control room 65 arranged at the front portion of the vehicle frame 61, an elevating platform arranged on the vehicle frame 61, a cantilever 64 arranged on the elevating platform, fixed on the cantilever 64 and positioned at The high-pressure spray bellows 30 at the rear of the vehicle frame 61, the liquid medicine delivery mechanism arranged on the vehicle frame 61, the walking wheels 62 arranged below the vehicle frame 61, and the driving device 63 arranged on the vehicl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com