Rapid-heat-absorption filter based on hollow fibers and application thereof

A filter and hollow technology, applied in applications, e-liquid filter elements, tobacco, etc., can solve the problems of limited contact area between materials and flue gas, difficulty in achieving rapid cooling of flue gas, and low stacking density, so as to improve heat exchange rate, Reduce the instantaneous temperature and improve the effect of specific surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

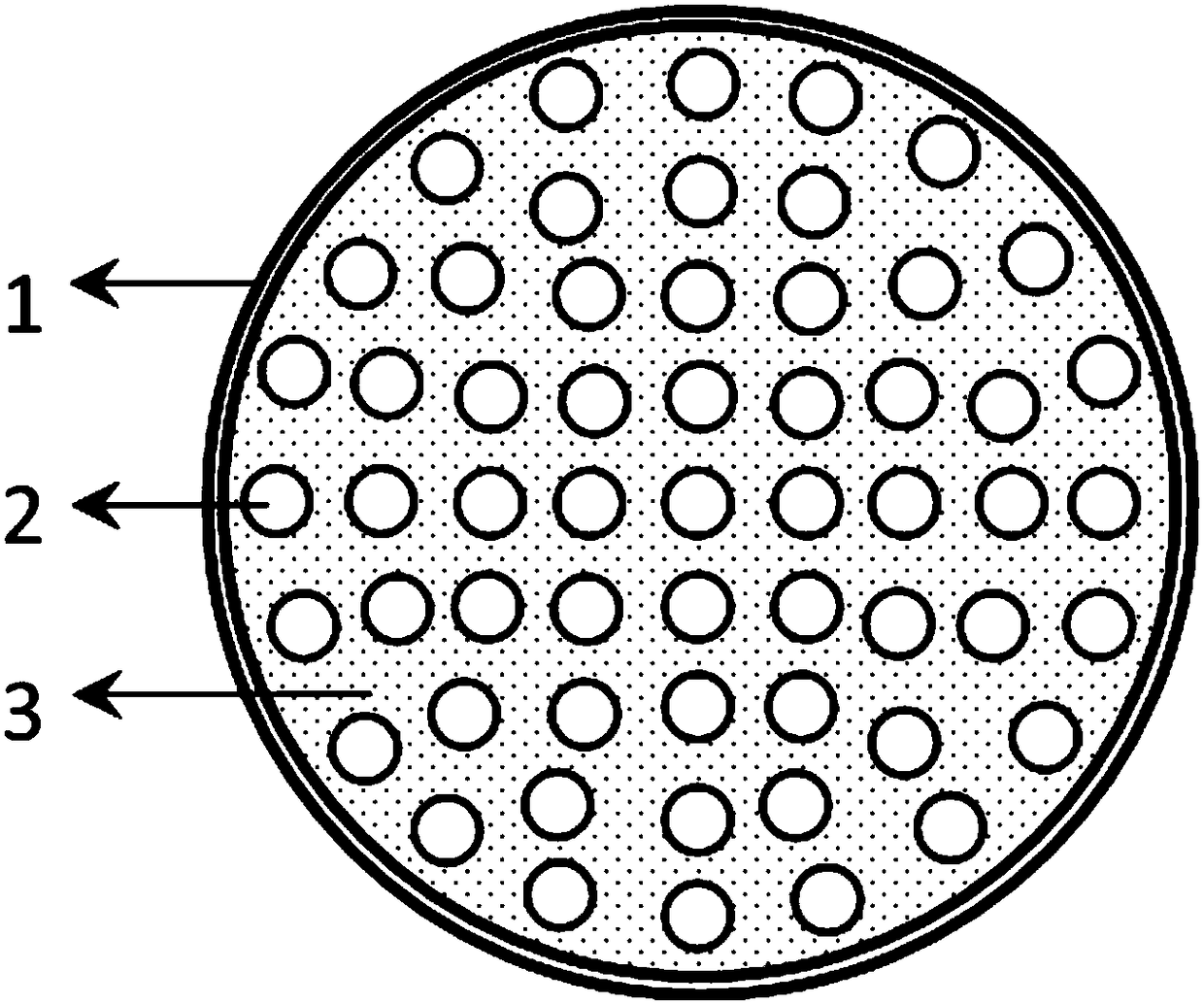

[0030] Such as figure 1 As shown, a fast heat-absorbing filter based on hollow fiber is wrapped by cigarette paper with several polyvinylidene fluoride hollow fiber ultrafiltration membranes arranged in parallel and coalesced into bundles to form a uniform cylindrical rod with a length of 0.2cm material. The polyvinylidene fluoride hollow fiber ultrafiltration membrane has a diameter of 0.2mm, a wall thickness of 0.04mm, and a filling rate of 80%. Polyvinylidene fluoride hollow fiber ultrafiltration membranes are filled with polyurethane to seal and fix the polyvinylidene fluoride hollow fiber ultrafiltration membranes.

Embodiment 2

[0032] Such as figure 1 As shown, a fast heat-absorbing filter based on hollow fiber is wrapped with cigarette paper to form a uniform length of 0.4cm Cylindrical rod. The sulfonated polysulfone-polysulfone hollow fiber ultrafiltration membrane has a diameter of 0.3mm, a wall thickness of 0.05mm, and a filling rate of 76%. The gap between the sulfonated polysulfone-polysulfone hollow fiber ultrafiltration membranes is filled with epoxy resin for sealing and fixing the sulfonated polysulfone-polysulfone hollow fiber ultrafiltration membranes.

Embodiment 3

[0034] Such as figure 1 As shown, a fast heat-absorbing filter based on hollow fiber is wrapped with cigarette paper to form a uniform cylindrical rod with a length of 0.6cm. material. The polyethersulfone hollow fiber ultrafiltration membrane has a diameter of 0.4mm, a wall thickness of 0.06mm, and a filling rate of 74%. The gap between the polyethersulfone hollow fiber ultrafiltration membranes is filled with organic silica gel for sealing and fixing the polyethersulfone hollow fiber ultrafiltration membranes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com