XnR wide-temperature and high-stability BaTiO3-based dielectric ceramic and preparation method thereof

A dielectric ceramic, high stability technology, applied in the field of BaTiO3-based dielectric ceramics and its preparation, can solve the problems of low dielectric constant, high temperature end can not reach 200 ℃, low "core-shell" structure formation rate, etc. Effect of temperature range, high room temperature dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

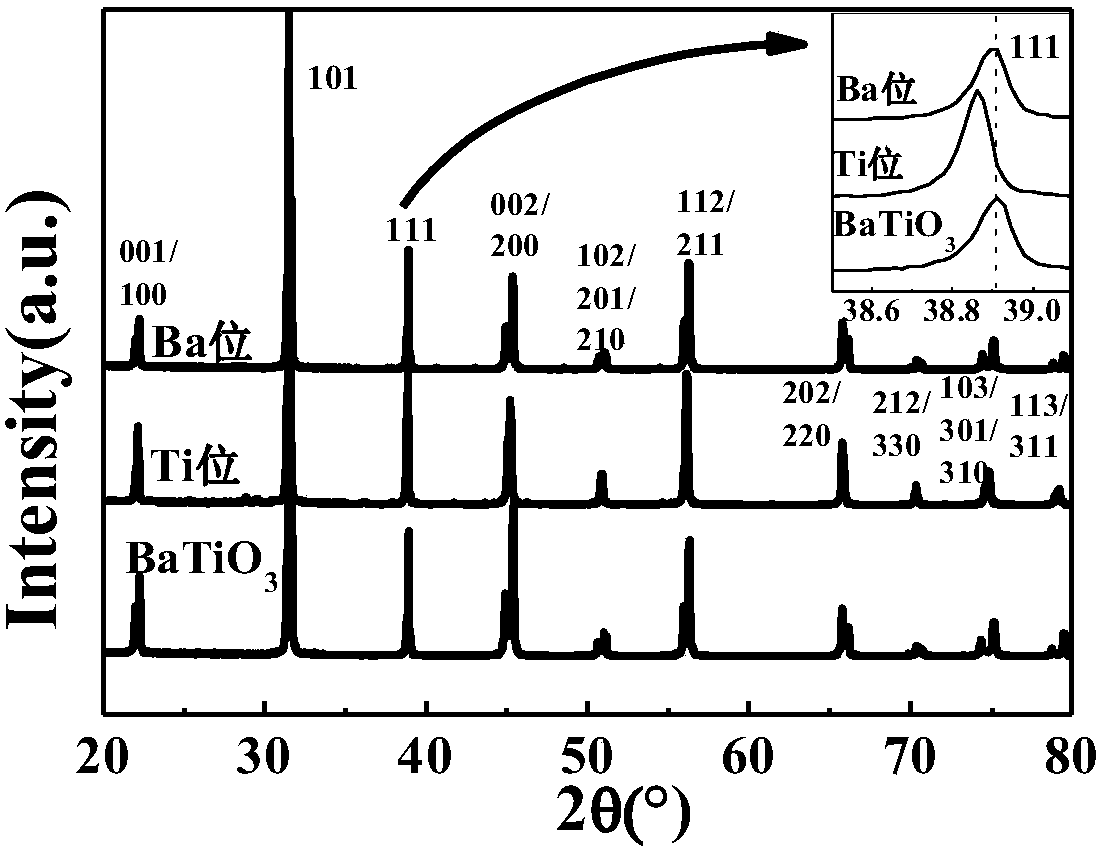

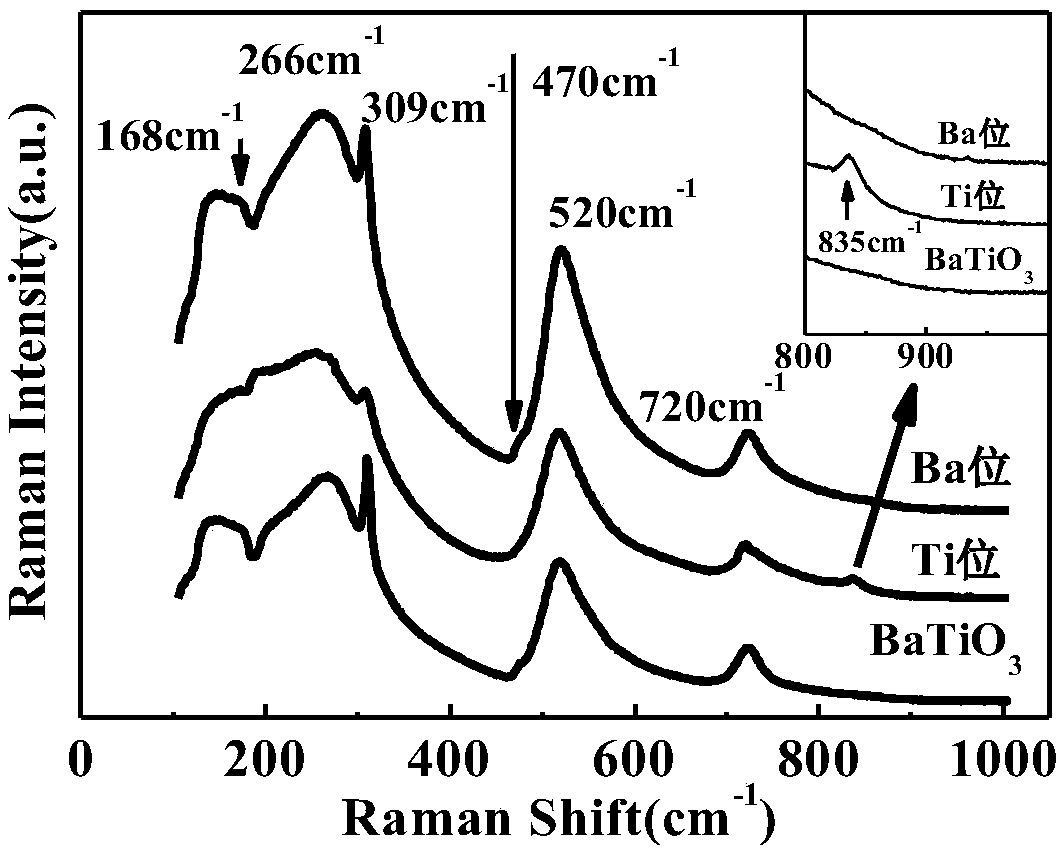

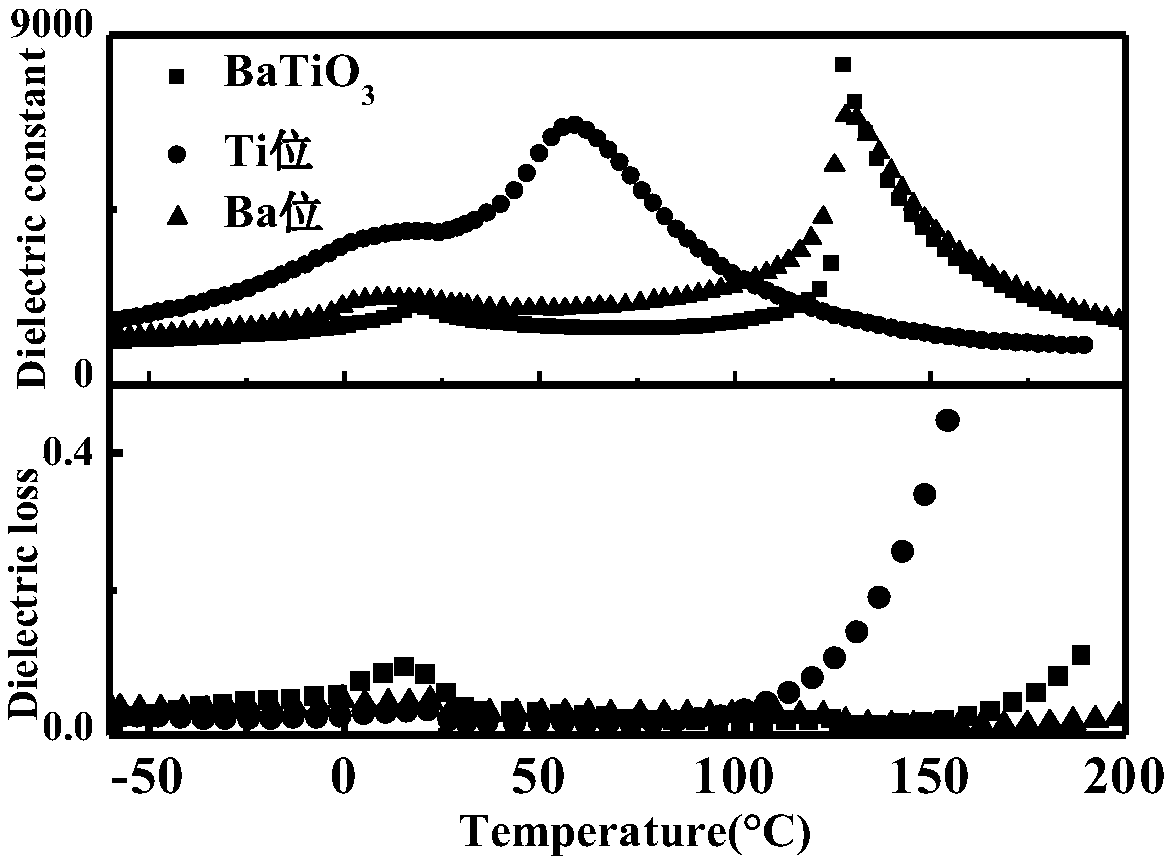

[0043] a BaTiO 3 Base dielectric ceramics, the chemical composition is (1-y)BaTi 1-x Ca x o 3-x -yBi(Zn 0.5 Ti 0.5 )O 3 , x=0.04, y=0.1.

[0044] The aforementioned BaTiO 3 The preparation method of substrate ceramics, comprises the steps:

[0045] (1) Preparation of BaTi 0.96 Ca 0.04 o 2.96 Powder: according to BaTi 0.96 Ca 0.04 o 2.96 Chemical composition weighing raw material: BaCO 3 (99%), TiO 2 (99%), CaCO 3 (99%), the weighed raw materials are put into the planetary ball mill tank, mixed with a certain proportion of absolute ethanol and zirconium balls for ball milling, the specific parameters are: the ball milling time is 8h, and the rotating speed is 1200r / min;

[0046] Pour the ball-milled slurry into a beaker and dry it in a blast drying oven for 24 hours. The oven temperature is set at 100°C. The dried powder is crushed with a mortar, and then placed in a round crucible at 1190°C. Pre-fired for 2 hours; the pre-fired powder was ball milled twice and...

Embodiment 2

[0052] a BaTiO 3 Base dielectric ceramics, the chemical composition is (1-y)BaTi 1-x Ca x o 3-x -yBi(Zn 0.5 Ti 0.5 )O 3 , x=0.04, y=0.13.

[0053] The aforementioned BaTiO 3 The preparation method of substrate ceramics, comprises the steps:

[0054] (1) Preparation of BaTi 0.96 Ca 0.04 o 2.96 Powder, according to BaTi 0.96 Ca 0.04 o 2.96 Chemical composition weighing raw material: BaCO 3 (99%), TiO 2 (99%), CaCO 3 (99%), the weighed raw material is put into the planetary ball mill jar, and the planetary ball mill is used, and the raw material is mixed with a certain proportion of absolute ethanol and zirconium balls for ball milling. The specific parameters are: the ball milling time is 8h, and the rotating speed is 1200r / min;

[0055] Pour the ball-milled slurry into a beaker and dry it in a blast drying oven for 20 hours. The oven temperature is set at 100°C. The dried powder is then crushed with a mortar and placed in a round crucible at 1190°C. Pre-fired for...

Embodiment 3

[0061] a BaTiO 3 Base dielectric ceramics, the chemical composition is (1-y)BaTi 1-x Ca x o 3-x -yBi(Zn 0.5 Ti 0.5 )O 3 , x=0.04, y=0.15.

[0062] The aforementioned BaTiO 3 The preparation method of substrate ceramics, comprises the steps:

[0063] (1) Preparation of BaTi 0.96 Ca 0.04 o 2.96 Powder, according to BaTi 0.96 Ca 0.04 o 2.96 Chemical composition weighing raw material: BaCO 3 (99%), TiO 2 (99%), CaCO 3 (99%), the weighed raw material is put into the planetary ball mill jar, and the planetary ball mill is used, and the raw material is mixed with a certain proportion of absolute ethanol and zirconium balls for ball milling. The specific parameters are: the ball milling time is 8h, and the rotating speed is 1200r / min;

[0064] Pour the ball-milled slurry into a beaker and dry it in a blast drying oven for 24 hours. The oven temperature is set at 100°C. The dried powder is crushed with a mortar and placed in a round crucible at 1250°C. Pre-fired for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com