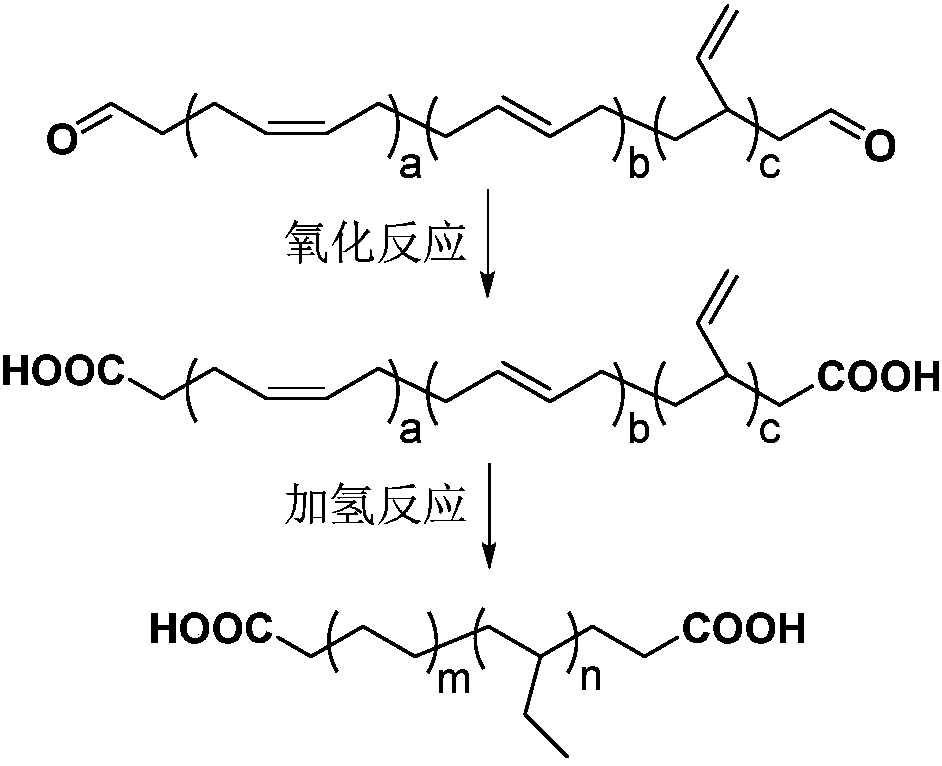

High-cis-1,4 content carboxyl-terminated polybutadiene liquid rubber and carboxyl-terminated polyethylene, and preparation method thereof

A technology for aldehyde-terminated polybutadiene and polybutadiene, which is applied in the field of preparing carboxyl-terminated polyethylene, can solve the problems of high raw material price, high application cost, difficult recovery and the like, and achieves good fluidity, low cost, high reaction mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of high cis-terminated aldehyde polybutadiene:

[0039] The preparation method refers to CN201410377717.8. The obtained high-cis-1,4 content aldehyde-terminated polybutadiene liquid rubber has a number average molecular weight of 500 g / mol and a molecular weight distribution of 1.9 as characterized by GPC.

[0040] Preparation of high cis-terminated carboxyl polybutadiene:

[0041] Take 2.00g of the above-mentioned high cis-1,4 content aldehyde-terminated polybutadiene liquid rubber, completely dissolve it in 10mL cyclohexane, then add 3.3mL acetone, so that the volume ratio of acetone / cyclohexane = 1 / 3, Keep the temperature at 30°C, add 1.5 mL of Jones reagent ([O] / [CHO]=4 / 1) dropwise, react for 4 hours, add a small amount of isopropanol to remove unreacted Jones reagent. After the solution is rotary evaporated, add n-hexane to dissolve again, filter and rotary steam to obtain high cis-1,4 content carboxyl-terminated polybutadiene liquid rubber, the number...

Embodiment 2

[0043] The preparation process of high cis-terminated aldehyde polybutadiene is the same as in Example 1;

[0044] Take 2.0 g of high cis-terminated polybutadiene with aldehyde groups, the cis-1,4 content is 95%, the number average molecular weight is 5100 g / mol, and the molecular weight distribution is 1.6. Completely dissolve in 10mL cyclohexane, then add acetone, make the volume ratio of acetone / cyclohexane=1 / 3, keep the temperature to 40°C, add the calculated amount of Jones reagent dropwise ([O] / [CHO]=4 / 1), react for 3 hours, add a small amount of isopropanol to remove unreacted Jones reagent. After the solution is rotary evaporated, add n-hexane to dissolve again, filter and rotary steam to obtain high cis-1,4 content carboxyl-terminated polybutadiene liquid rubber, the number average molecular weight is 5000 / mol and the molecular weight distribution is 1.6 as characterized by GPC ,through 1 H NMR and 13 The microstructure characterized by C NMR was cis-1,4 with 95% ...

Embodiment 3

[0046] The preparation process of high cis-terminated aldehyde polybutadiene is the same as in Example 1;

[0047] Take 2.0 g of high cis-terminated polybutadiene with aldehyde groups, the cis-1,4 content is 96%, the number average molecular weight is 3100 g / mol, and the molecular weight distribution is 1.9. Completely dissolve in 10mL cyclohexane, then add acetone, make the volume ratio of acetone / cyclohexane=1 / 3, keep the temperature to 25°C, add the calculated amount of Jones reagent dropwise ([O] / [CHO]=4 / 1), react for 5 hours, add a small amount of isopropanol to remove unreacted Jones reagent. After the solution is rotary evaporated, add n-hexane to dissolve again, filter and rotary steam to obtain high cis-1,4 content carboxyl-terminated polybutadiene liquid rubber, the number average molecular weight is 3000 / mol and the molecular weight distribution is 1.9 as characterized by GPC ,through 1 H NMR and 13 The microstructure characterized by C NMR was cis-1,4 content o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com