High-molecular polymer with self restoration function as well as preparation method and application thereof

A high-molecular polymer, self-healing technology, applied in the direction of organic insulators, plastic/resin/wax insulators, electrical components, etc., can solve problems such as the inability to achieve self-repairing, and achieve the effect of easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

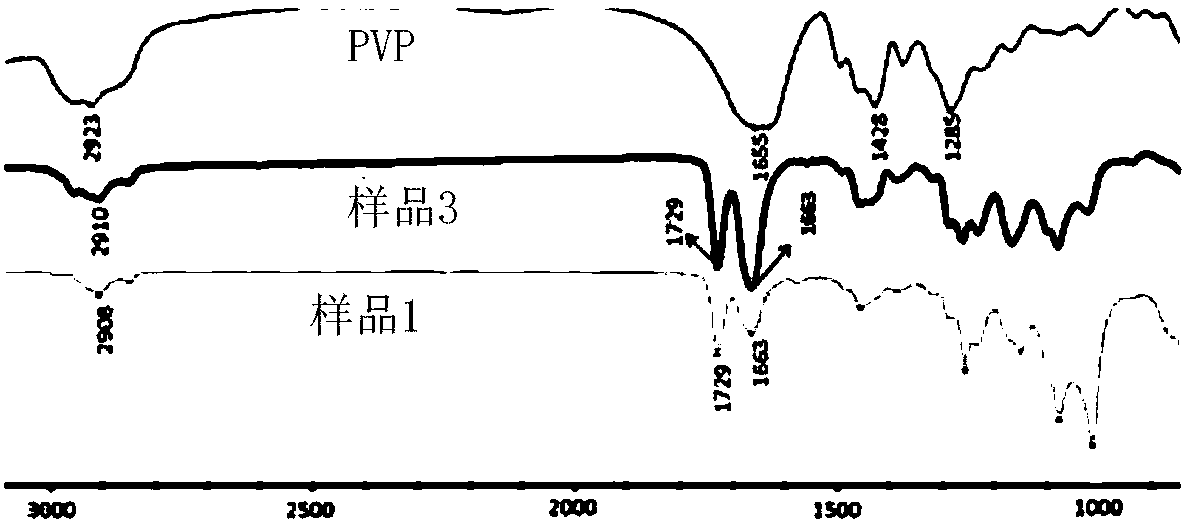

Embodiment 1

[0038] (1) Disperse 50g of β-CD cyclodextrin in 1200mL of deionized water, slowly add 13g of p-toluenesulfonyl chloride under vigorous stirring, react at room temperature for 12 hours, add 20g of NaOH, filter to remove excess p-toluene Sulfonyl chloride, add ammonium chloride until the pH value of the solution is 8;

[0039] (2) Place the solution obtained above in a refrigerator at 4°C to cool, after a period of time, suction and filter to obtain a precipitate, dissolve the precipitate in water, repeat this step at least twice to obtain the intermediate product TOS-CD;

[0040] (3) Take 0.5g NH 2 -Al 2 o 3 Dissolve NPs in 25ml dimethyl sulfoxide, stir for 30min, add an appropriate amount of TOS-CD obtained in step (2), adjust the pH to 7~8 when TOS-CD is completely dissolved; then, under the protection of inert gas, heat to 65 ℃, and reacted for 12 hours; centrifuged to remove dimethyl sulfoxide, and then washed 3 times with ethanol to obtain the product main molecule CD-...

Embodiment 2

[0047] (1) Disperse 50g of β-CD cyclodextrin in 1200mL of deionized water, slowly add 13g of p-toluenesulfonyl chloride under vigorous stirring, react at room temperature for 12 hours, add 20g of NaOH, filter to remove excess p-toluene Sulfonyl chloride, add ammonium chloride until the pH value of the solution is 8;

[0048] (2) Place the solution obtained above in a refrigerator at 4°C to cool, after a period of time, suction and filter to obtain a precipitate, dissolve the precipitate in water, repeat this step at least twice to obtain the intermediate product TOS-CD;

[0049] (3) Take 0.5g NH 2 -Al 2 o 3 Dissolve NPs in 25ml dimethyl sulfoxide, stir for 30min, add an appropriate amount of TOS-CD obtained in step (2), adjust the pH to 7~8 when TOS-CD is completely dissolved; then, under the protection of inert gas, heat to 65 ℃, and reacted for 12 hours; centrifuged to remove dimethyl sulfoxide, and then washed 3 times with ethanol to obtain the product main molecule CD-...

Embodiment 3

[0056] (1) Disperse 50g of β-CD cyclodextrin in 1200mL of deionized water, slowly add 13g of p-toluenesulfonyl chloride under vigorous stirring, react at room temperature for 12 hours, add 20g of NaOH, filter to remove excess p-toluene Sulfonyl chloride, add ammonium chloride until the pH value of the solution is 8;

[0057] (2) Place the solution obtained above in a refrigerator at 4°C to cool, after a period of time, suction and filter to obtain a precipitate, dissolve the precipitate in water, repeat this step at least twice to obtain the intermediate product TOS-CD;

[0058] (3) Take 0.5g NH 2 -Al 2 o 3 Dissolve NPs in 25ml dimethyl sulfoxide, stir for 30min, add an appropriate amount of TOS-CD obtained in step (2), adjust the pH to 7~8 when TOS-CD is completely dissolved; then, under the protection of inert gas, heat to 65 ℃, and reacted for 12 hours; centrifuged to remove dimethyl sulfoxide, and then washed 3 times with ethanol to obtain the product main molecule CD-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com