Water-based industrial artistic coating and preparation method thereof

An art paint, water-based technology, applied in art paints, epoxy resin paints, coatings, etc., can solve the problems of injury to production workers, pollution of the environment, large consumption, etc., to achieve low unit cost, high solid content, and easy operation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

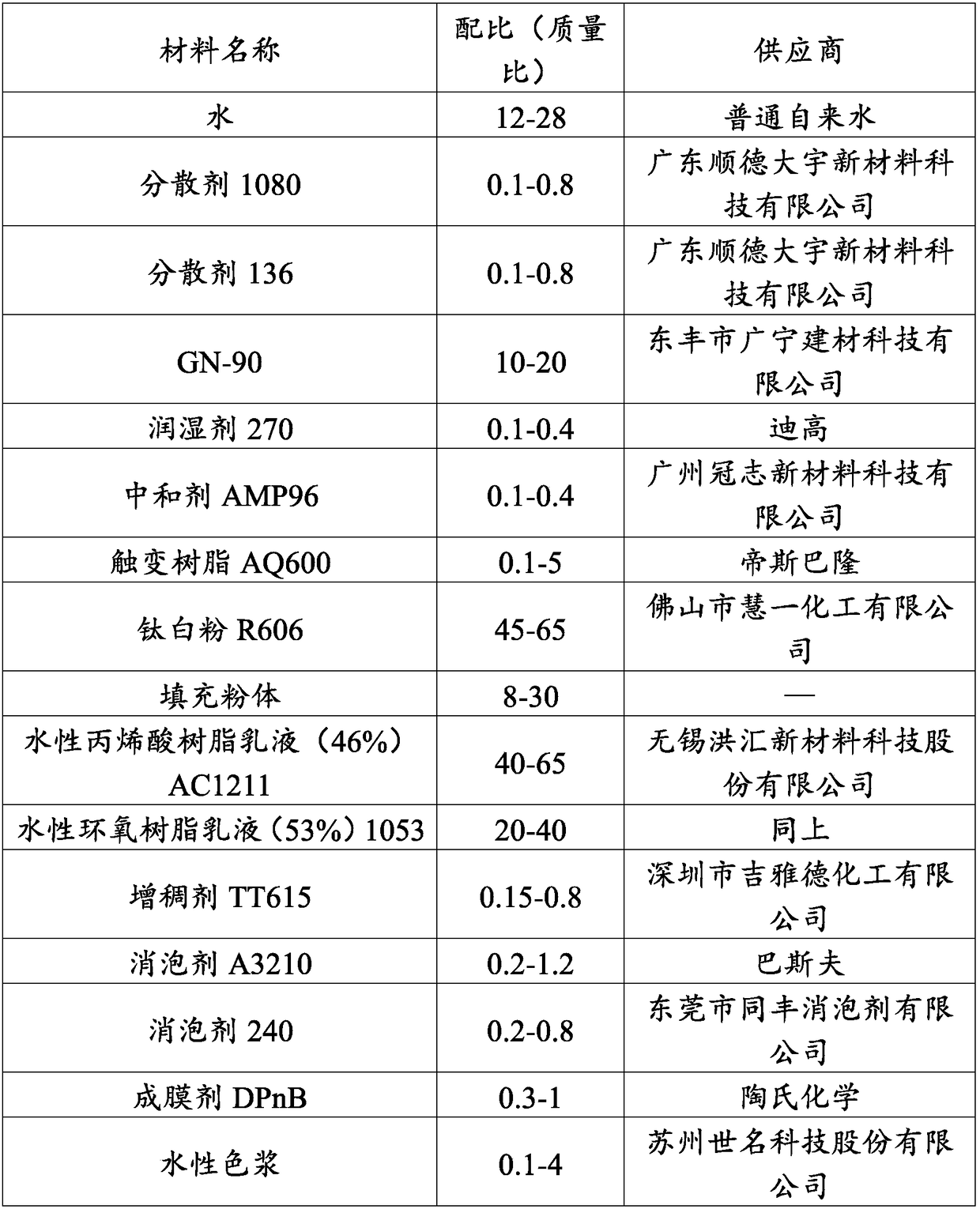

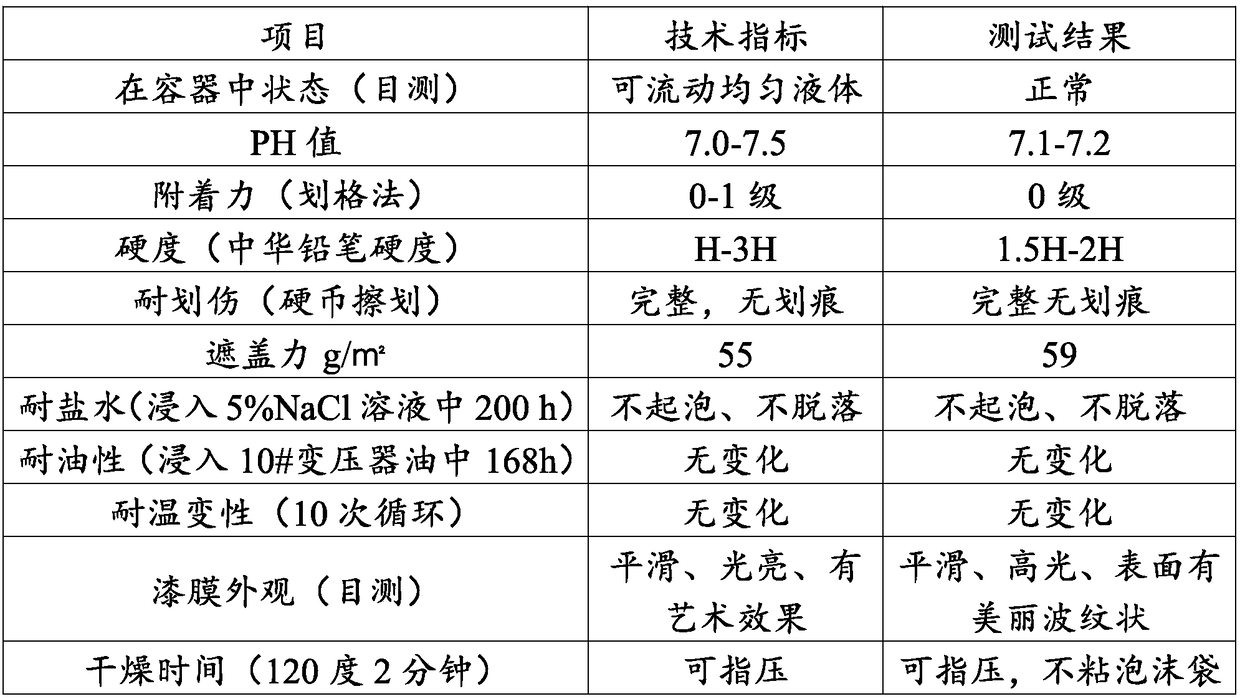

Method used

Image

Examples

preparation example Construction

[0069] A preparation method of water-based industrial art paint, the steps comprising:

[0070] Add water to the container according to 80% of the required amount, start the mixer at a speed of 200-400 rpm, add dispersant 1080, dispersant 136, wetting agent 270, and neutralizer AMP96 in order to disperse for 1 minute;

[0071] Add thixotropic resin AQ600 and disperse at 1000 rpm for 5-10 minutes;

[0072] Add titanium dioxide and disperse at 1200-1500 rpm for 45-60 minutes;

[0073]Add 50% defoamer A3210 at 800 rpm for 10-15 minutes;

[0074] Add 50% defoamer 240 at 500 rpm for 10-15 minutes;

[0075] The above is used as a semi-finished product S for standby;

[0076] Weigh a sufficient amount of water-based acrylic resin emulsion with a content of 46%, put it into a special container, stir at 800 rpm for 3-5 minutes, add a water-based epoxy resin emulsion with a content of 53%, and continue stirring for 3-5 minutes;

[0077] Add GN-90 and stir at 500-600 rpm for 5-10 min...

Embodiment 1

[0092] Add water to the container according to 80% of the required amount, start the mixer, and rotate at 200 rpm, add dispersant 1080, dispersant 136, wetting agent 270, and neutralizer AMP96 to disperse for 1 minute; add thixotropic resin AQ600 at 1000 Rotate and disperse for 5 minutes; add titanium dioxide and disperse at 1200 rpm for 45 minutes; add 50% defoamer A3210 at 800 rpm for 10 minutes; add 50% defoamer 240 at 500 rpm for 10 minutes, as a semi-finished product S spare.

Embodiment 2

[0094] Add GN-90 and stir at 500 rpm for 5 minutes; add film-forming agent DPnB and stir at 500 rpm for 5 minutes; add filling powder and stir at 800 rpm for 15 minutes; add the semi-finished product S in Example 1, and stir at 800 rpm for 20 minutes; Add the remaining defoamer A3210 and stir at 400 rpm for 5 minutes; add the remaining defoamer 240 and stir at 400 rpm for 3-5 minutes; add thickener TT615 and stir at 500 rpm for 5 minutes; add color paste and stir for 10 minutes to prepare into the desired color; use the remaining 20% of the water to wash the container, and add the washing water to the paint for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com