Automatic solid waste impurity electromagnetic screening device and method

A screening device and electromagnetic technology, applied in the fields of magnetic separation, solid separation, chemical instruments and methods, etc., can solve the problems of small particle size of magnetic metal particles and the removal of magnetic metal particles that cannot be magnetic, so as to avoid secondary mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

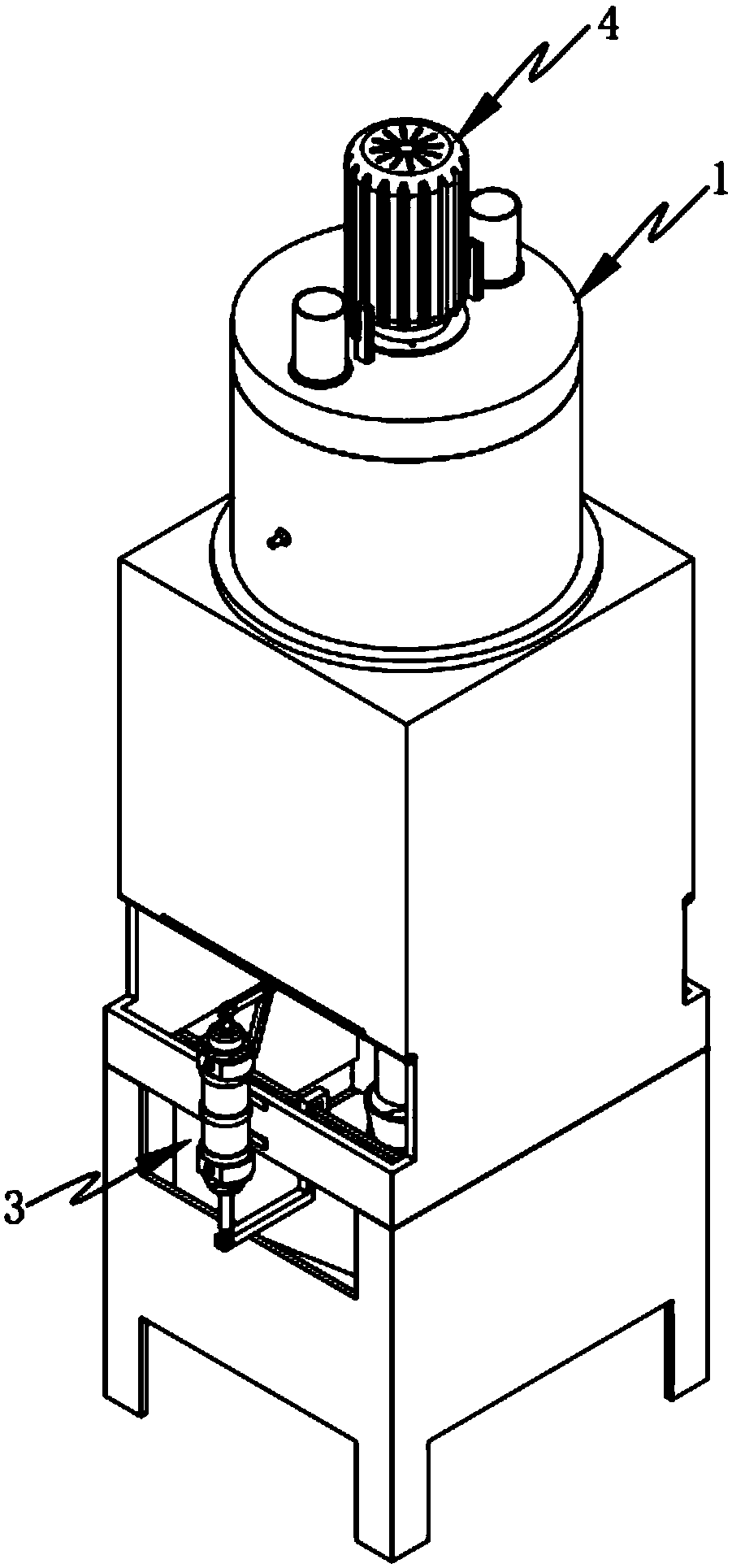

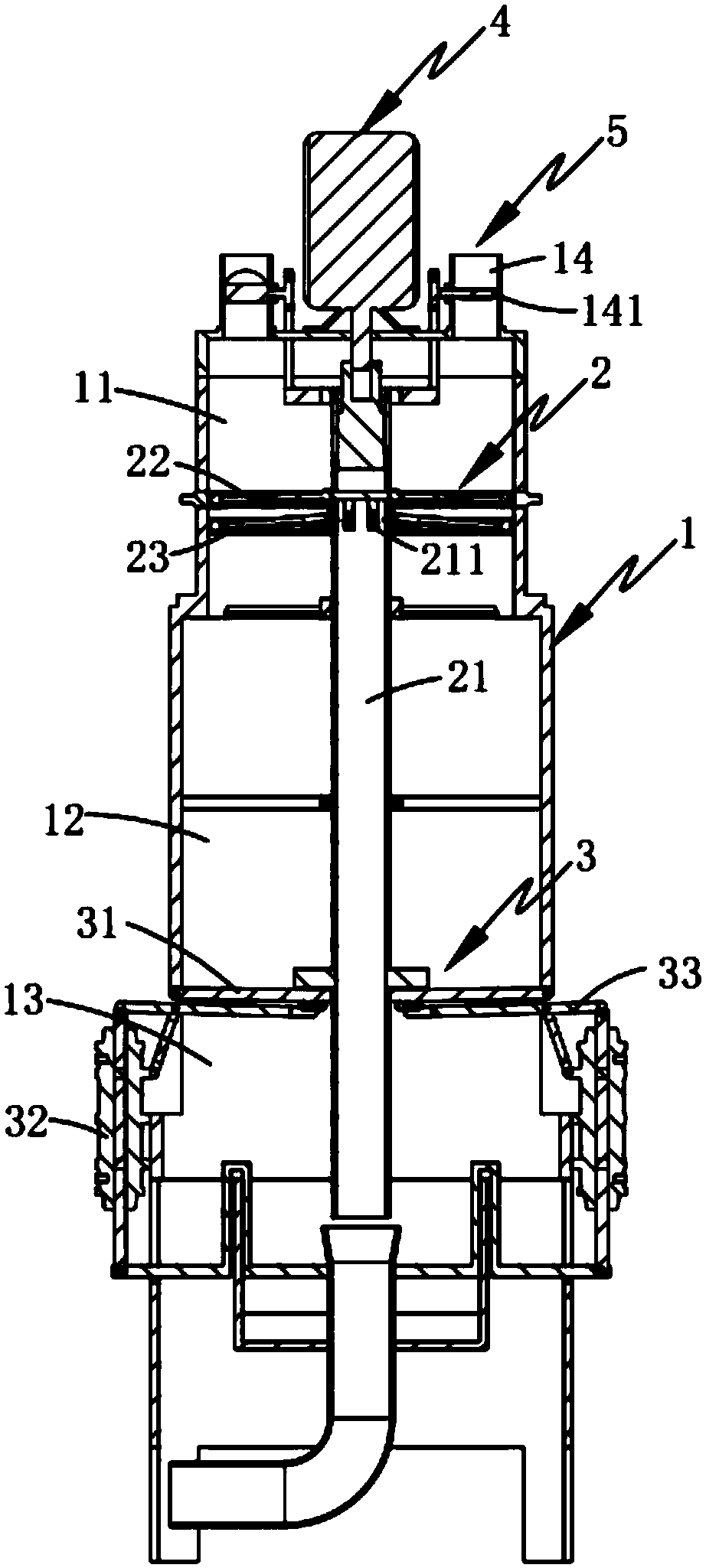

[0052] Such as figure 1 , figure 2 , image 3 , Figure 4 , Image 6 , Figure 8 with Picture 9 As shown, an automatic electromagnetic screening device for solid waste and impurities includes a box body 1, which is divided into a screen zone 11, a storage zone 12, and a discharge zone 13 from top to bottom, and also includes:

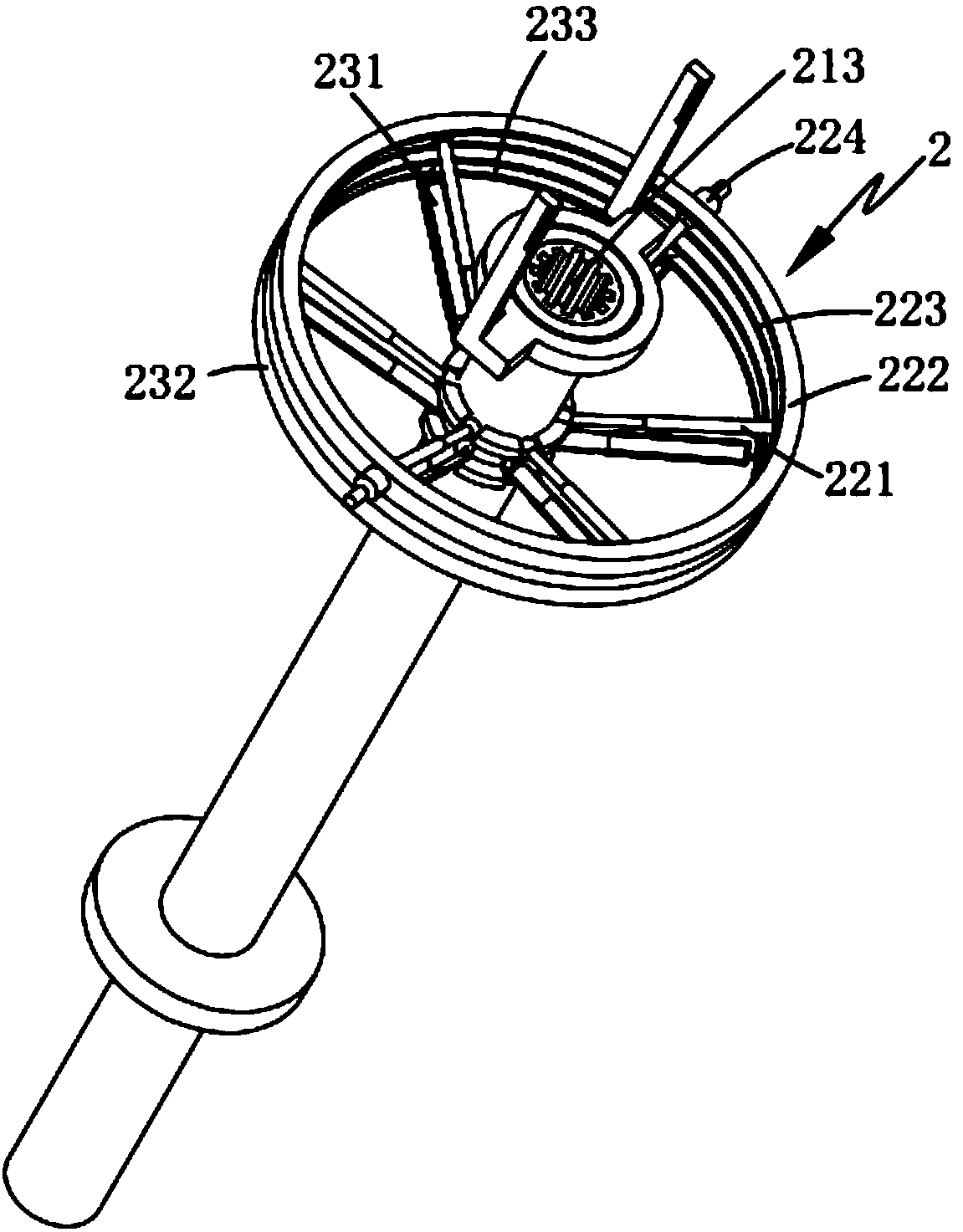

[0053] The electromagnetic screening mechanism 2 is arranged in the box 1 and includes a rotating shaft 21 vertically slidably arranged in the box 1. The inside of the rotating shaft 21 is hollow and arranged along the From top to bottom in the axial direction, an electromagnetic screening assembly 22 and a receiving assembly 23 are arranged in sequence, and the electromagnetic screening assembly 22 and the receiving assembly 23 are both arranged in the screen zone 11, the electromagnetic screening assembly 22 It includes a plurality of shift rods 221 for sieving solid waste impurities, and the material receiving assembly 23 includes a plurality of receiv...

Embodiment approach

[0057] As a preferred embodiment, the electromagnetic screening assembly 22 further includes:

[0058] The magnetic permeable ring 222, the permeable ring 222 is arranged in a circular ring shape, which is fixedly arranged inside the screen section 11, and the inner wall of which is provided with a continuous guide groove 223, the permeable ring 222 is energized by the electromagnet 224 With magnetism; a number of the levers 221 are arranged in a circumferential array along the central axis of the shaft 21, one end of which is slidably arranged in the guide groove 223, the magnetism is transmitted by the magnetic ring 222, and the other end is The rotating shaft 21 is hinged, and the lever 221 is telescopically arranged.

[0059] It should be noted that the magnetic permeable ring 222 is connected to the electromagnet 224, and the electromagnet 224 is electrically connected to the numerical control box through a relay switch. After the electromagnet 224 is energized and magnetized,...

Embodiment 2

[0070] Figure 5 with 10 It is a schematic structural diagram of Embodiment 2 of an automatic electromagnetic screening device for solid waste impurities of the present invention; Figure 5 with 10 As shown, the components that are the same as or corresponding to the first embodiment use the reference numerals corresponding to the first embodiment. For simplicity, only the differences from the first embodiment are described below. The second embodiment and figure 1 The difference of the first embodiment shown is:

[0071] An automatic electromagnetic screening device for solid waste impurities. The hinged position of the rotating shaft 21 and the material receiving trough 231 is provided with a feed port 211, and the feed port 211 is provided with a sealing plate 234. The top of the plate 234 is rotatably connected with the rotating shaft 21.

[0072] Further, a limit hook 235 is provided at one end of the material receiving groove 231 that is hinged with the rotating shaft 21, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com