Rebar reinforced polypropylene corrugated pipe and manufacturing method thereof

A technology of threaded steel bars and corrugated pipes, applied in the field of threaded steel bar reinforced polypropylene bellows pipes and its manufacture, can solve the problems of easy delamination of steel and plastic, poor impact performance, corrosion of steel strips, etc., and achieve enhanced synergistic compression resistance and Mutual protection, avoidance of differences in expansion coefficient and shrinkage, effect of excellent compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach ( 1

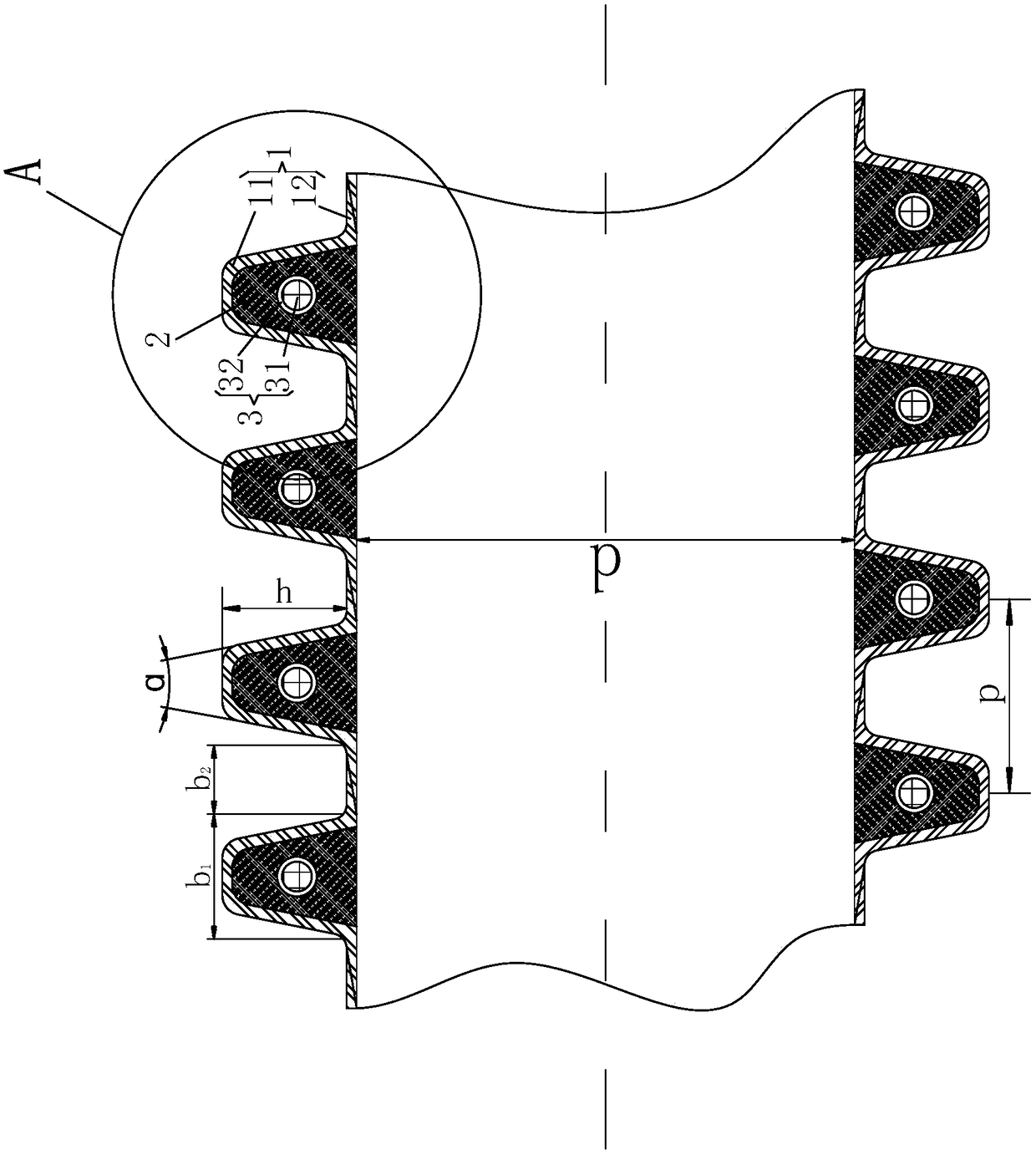

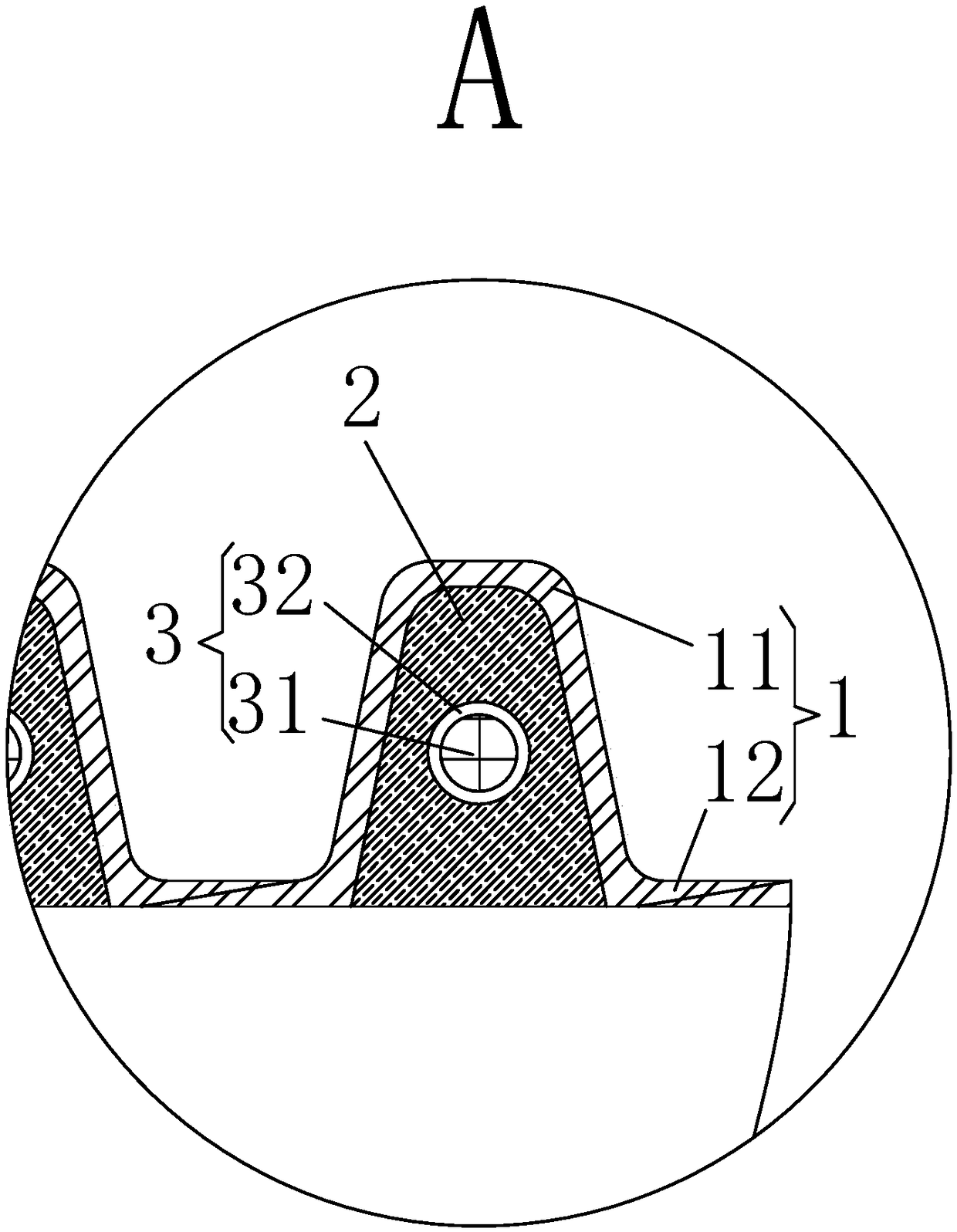

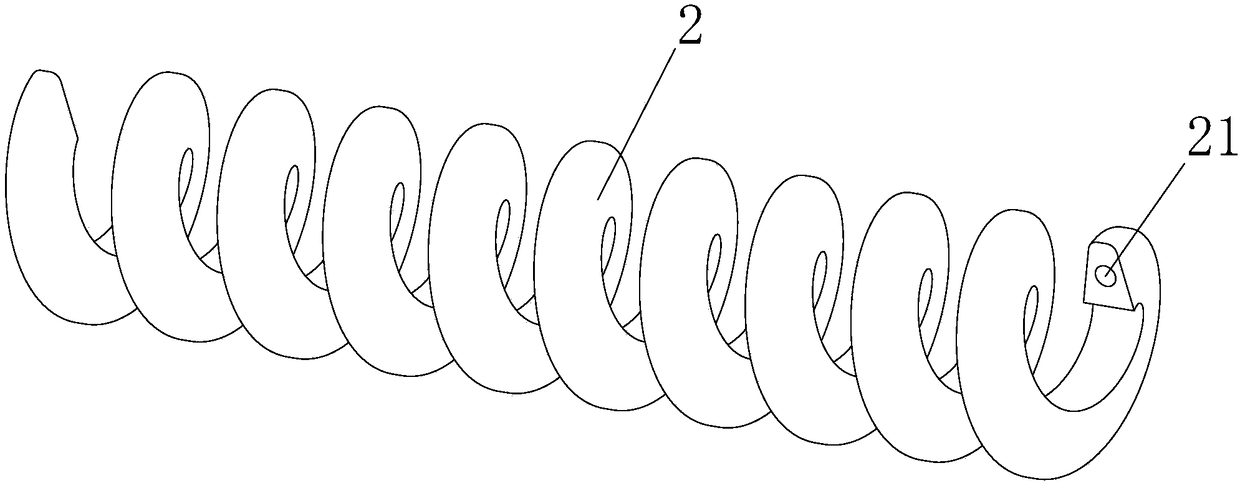

[0032] Such as Figure 1-4 Shown is a threaded steel reinforced polypropylene corrugated pipe provided by the present invention, which is characterized in that the corrugated pipe includes an outer layer 1, a reinforced layer 2, and a plastic-coated steel bar layer 3 arranged in the reinforced layer 2, the outer layer 1 includes outer layer crests 11 and outer layer troughs 12 arranged alternately and extending helically along the axial direction of the bellows, the inner surface of the outer layer crests 11 is a spiral cavity, and the reinforcing layer 2 is a solid crest structure and extend spirally along the axial direction of the bellows, the reinforcement layer 2 is located in the spiral cavity, the outer surface of the reinforcement layer 2 is attached and fixed to the inner surface of the outer wave peak 11 and the inner surface of the reinforcement layer 2 flush with the inner surface of the outer layer trough 12, the cross-sectional area of the plastic-coated steel ...

specific Embodiment approach ( 2

[0037] A method for manufacturing corrugated polypropylene pipe reinforced with threaded steel bars, characterized in that: the method comprises the following steps:

[0038] ①Heat the straight-line threaded steel bars to control the surface temperature at 250°C-280°C, and at the same time melt the grafted modified polyolefin resin at 180°C-220°C; then melt the grafted The modified polyolefin resin is evenly applied on the surface of the linear threaded steel bar profile, and the thickness of the coating is controlled at 0.8mm to 1.2mm. After cooling, the grafted modified polyolefin resin is cured on the surface of the linear threaded steel bar profile and tightly bonded. , to obtain a linear plastic-coated reinforcement layer;

[0039] ②When performing step ①, melt the polypropylene material used to make the reinforcement layer 2 at the same time, and control the melting temperature at 180°C to 250°C. Introduce and fix the plastic-coated linear threaded steel bar in step ① in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com