Glass fiber wetting agent, preparation method and uses thereof

A technology of glass fiber and sizing agent, applied in the field of glass fiber sizing agent and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

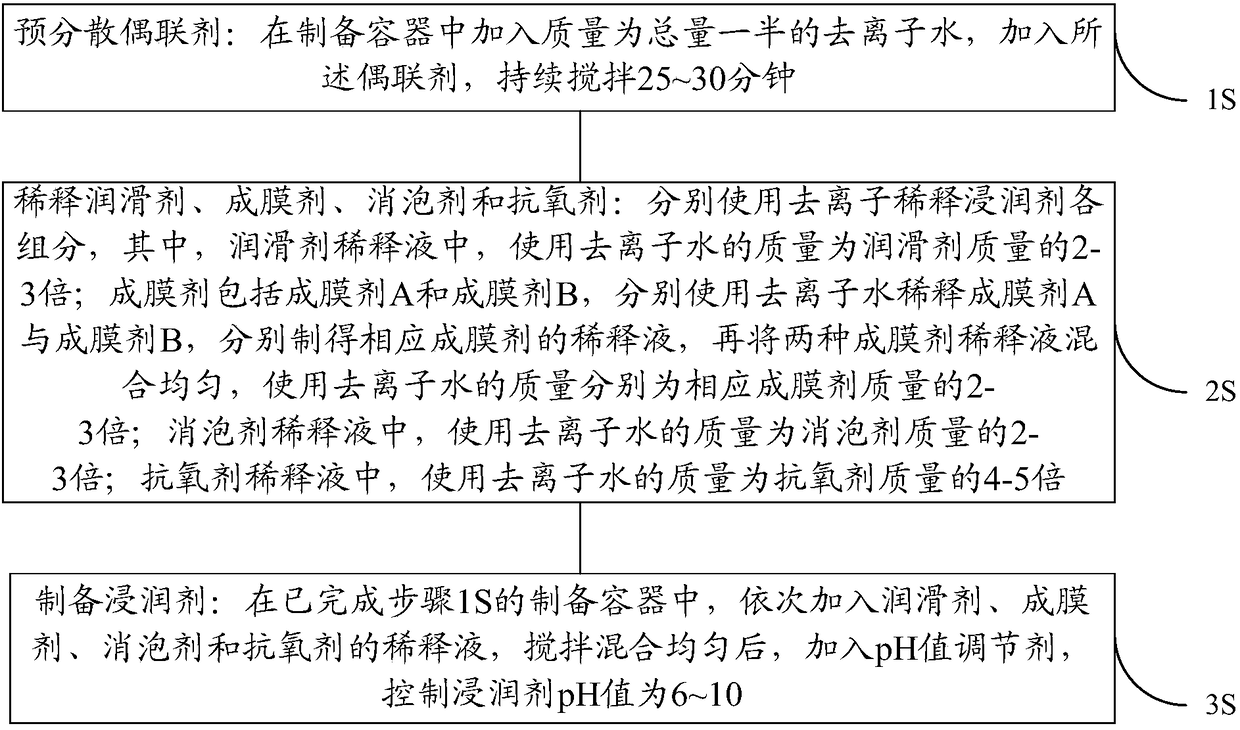

Method used

Image

Examples

Embodiment 1

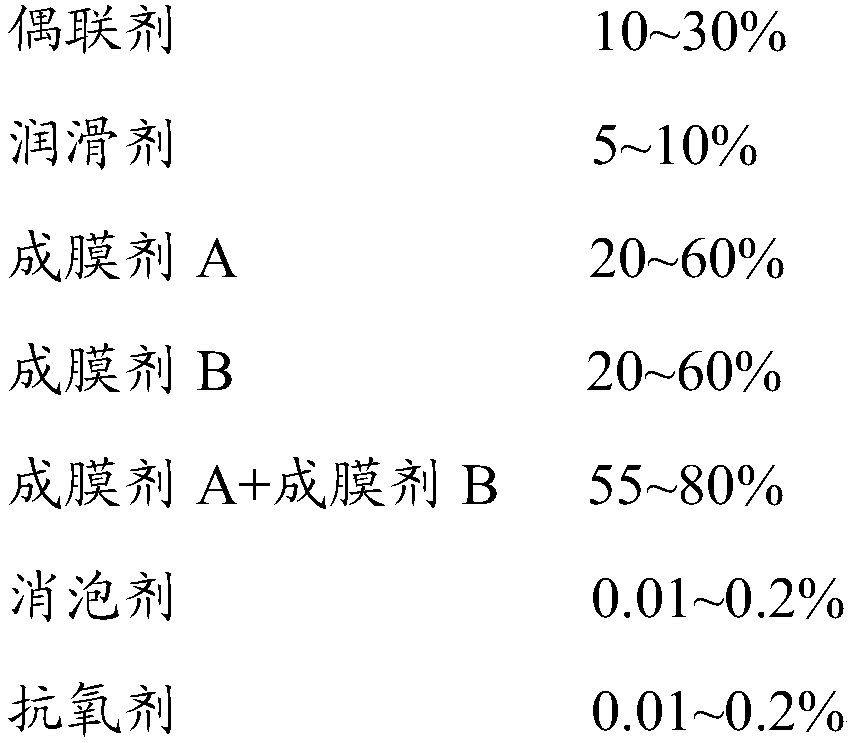

[0060] Weigh each component according to the sizing agent formula, wherein the water content accounts for 96.5% of the total mass of the sizing agent, and the solid mass of each component accounts for the total solid mass of the sizing agent as follows: coupling agent 10%, lubricant 10%, 20% of film-forming agent A, 59.34% of film-forming agent B, 0.01% of defoamer, 0.15% of antioxidant, 0.5% of pH regulator, and the total solid content ratio of each component is 100%.

[0061] Among them, the coupling agent is a bisaminosilane coupling agent, the product grade is A-1120; the lubricant is microcrystalline wax, the product grade is Hydrolube 496 of McMann; the film-forming agent A is a relatively high molecular weight polypropylene emulsion, the product The grade is Michelman’s FGlass X35; the film-forming agent B is a low molecular weight polypropylene wax emulsion, and the product grade is Michelman’s PP2-01; the defoamer is organosiloxane BYK019; Sodium phosphate; pH adjuste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com